Automatic Bundling Pipe Bagging Machine

An automatic strapping and bagging machine technology, which is applied in the direction of strapping materials, strapping machine parts, external supports, etc., can solve the problems of large space occupation, inconvenience for workers to move equipment, long packaging time, etc., and achieve small footprint , Save the transshipment process, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

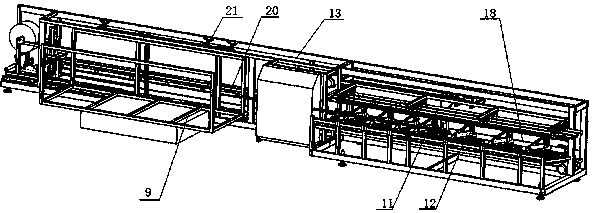

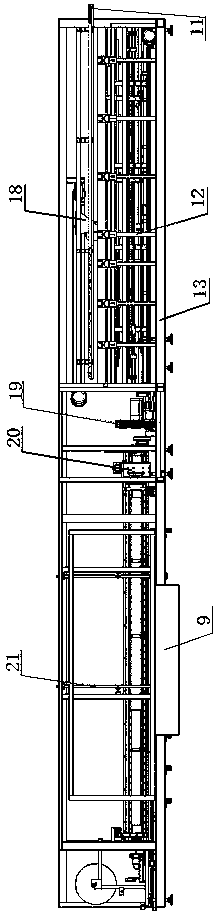

[0046] Such as figure 1 and figure 2 As shown, an automatic binding pipe bagging machine includes a frame 13, and the frame 13 is provided with a turning frame 11 and a material holding and pressing mechanism 12, and the turning frame 11 is located above the holding and pressing material 12 , used to introduce the pipes to be bundled and bagged outside, and turn the pipes into the holding and pressing mechanism 12, which is used to control the orderly rolling of the pipes, and the back of the holding and pressing mechanism 12 is from From right to left, a pushing mechanism 18, a binding mechanism 19 and a bagging mechanism 20 are arranged on the same horizontal axis in sequence. Under the push of the pushing mechanism 18, the pipes are first bundled in the binding mechanism 19, and then bagged in the bagging mechanism 20. , the pipe after bagging is unloaded into the external charging rack 22 through the liftable unloading mechanism 21 .

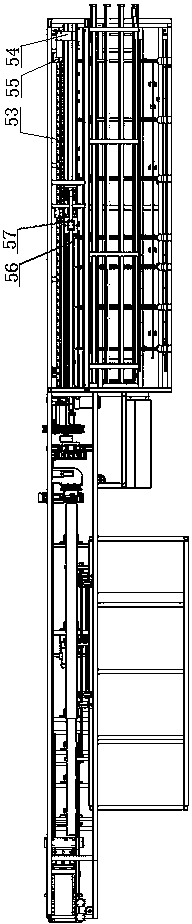

[0047] Such as image 3 , Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com