Speed changing type straw briquetting machine and application thereof

A straw briquetting machine and straw technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems affecting work efficiency, easy to break, high energy consumption, etc., to improve extrusion strength and efficiency, Elimination of clogging and reduction of production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

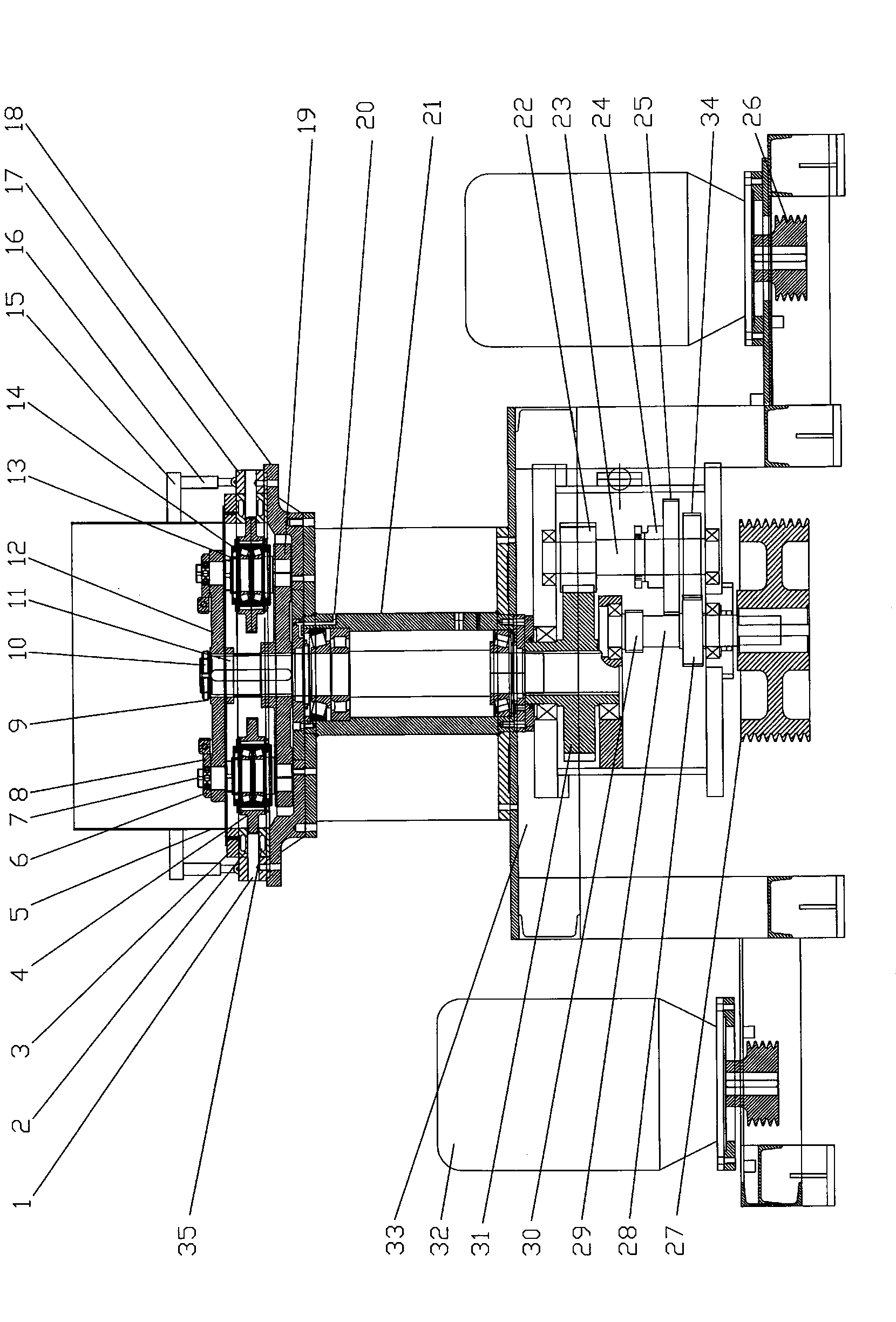

[0028] Example 1 Variable speed straw briquetting machine

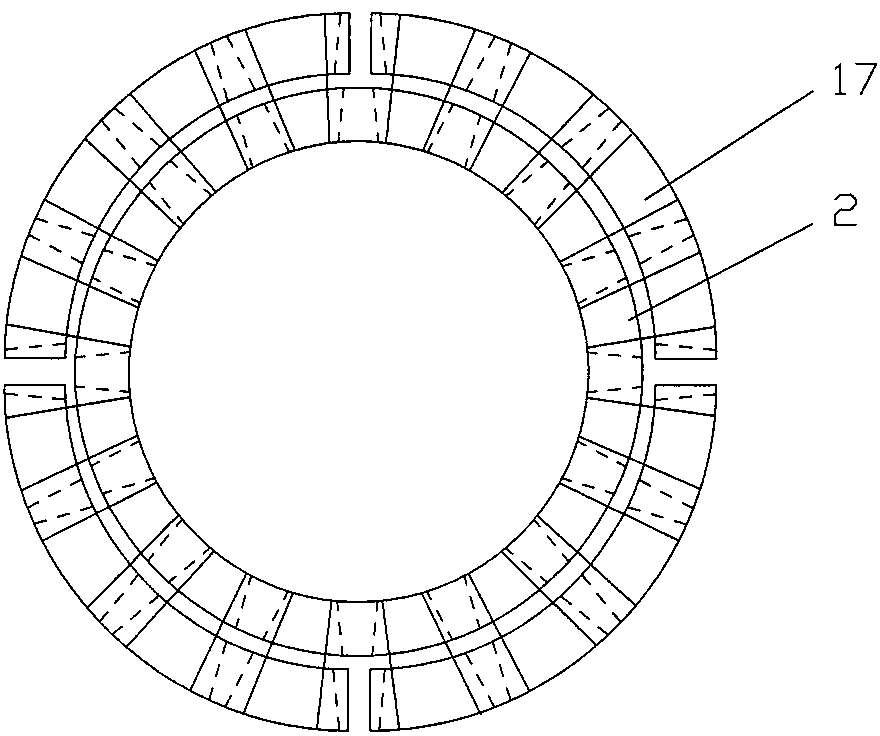

[0029] Such as figure 1 As shown, the variable-speed straw briquetting machine includes a frame 33, a motor 32, a main shaft 11, a pinch wheel shaft 7, a pinch wheel 4 and a module I2, the main shaft 11 is located in the housing 21, and the two motors 32 are placed symmetrically on the frame 33 The two sides of the two motors 32 and the main shaft 11 are connected through a transmission transmission. The transmission is provided with a drive shaft 29 and an intermediate shaft 23. The drive shaft 29 is connected to the motor pulley 26 through a driven pulley 27. The middle The driving wheel 22 of the shaft 23 is connected to the main shaft 11 through the driven wheel 31. The first gear 30 and the second gear 28 are fixedly set on the drive shaft 29. The intermediate shaft 23 is covered with a movable speed change wheel 24, a speed change wheel 24 There is a primary gear 34 meshing with the first gear 30 and a secon...

Embodiment 2

[0030] Example 2 Application of Variable Speed Straw Briquetting Machine

[0031] Application of the variable-speed straw briquetting machine described in Example 1 in the briquetting of straw.

[0032] The briquette forming method for corn stalks: 1) Crush the corn stalks into 10mm pieces; 2) Treat the corn stalk pieces in an oven at 110°C for 8-10 hours; 3) Adjust the moisture content of the corn stalk pieces to control the moisture content 10%; 4) Add corn stalk fragments into the straw briquetting machine in Example 1 for molding.

Embodiment 3

[0033] Example 3 Application of Variable Speed Straw Briquetting Machine

[0034] Application of the variable-speed straw briquetting machine described in Example 1 in the briquetting of straw.

[0035] The briquette forming method for corn stalks: 1) Crush the corn stalks into 20mm pieces; 2) Treat the corn stalk pieces in an oven at 110°C for 8-10 hours; 3) Adjust the moisture content of the corn stalk pieces to control the moisture content 30%; 4) After mixing the corn stalk fragments and corn starch according to the ratio of 9:0.6, they were added to the straw briquetting machine of Example 1 for molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com