Anti-turnover device for track running vehicle

An anti-dumping and track technology, applied in the field of vehicles, can solve the problems of no anti-dumping device, tensioned vehicle rollover, hooks without guiding functions, etc., and achieve the effect of convenient clearance adjustment, vehicle tipping prevention and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

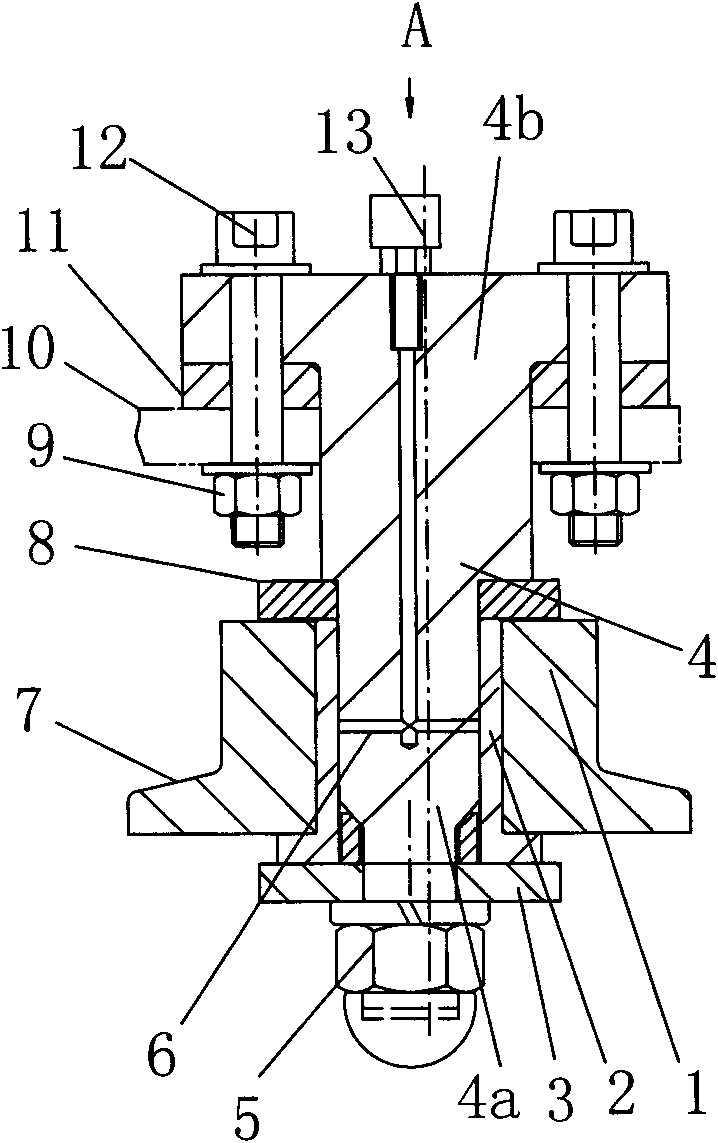

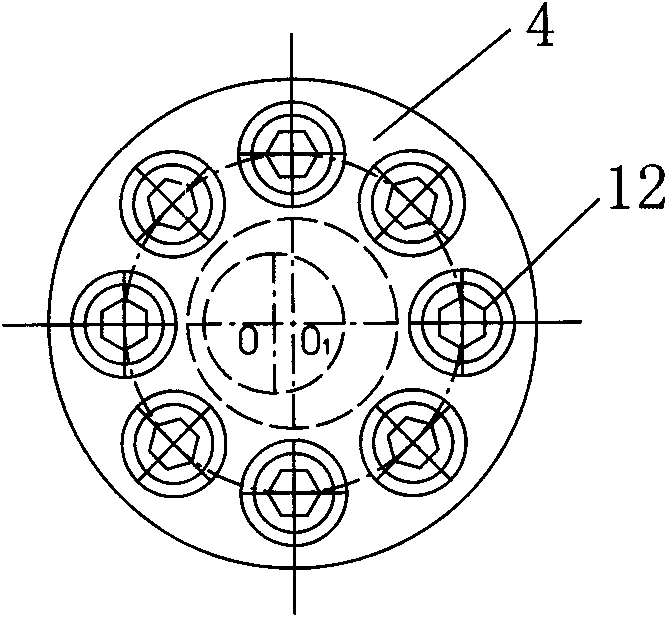

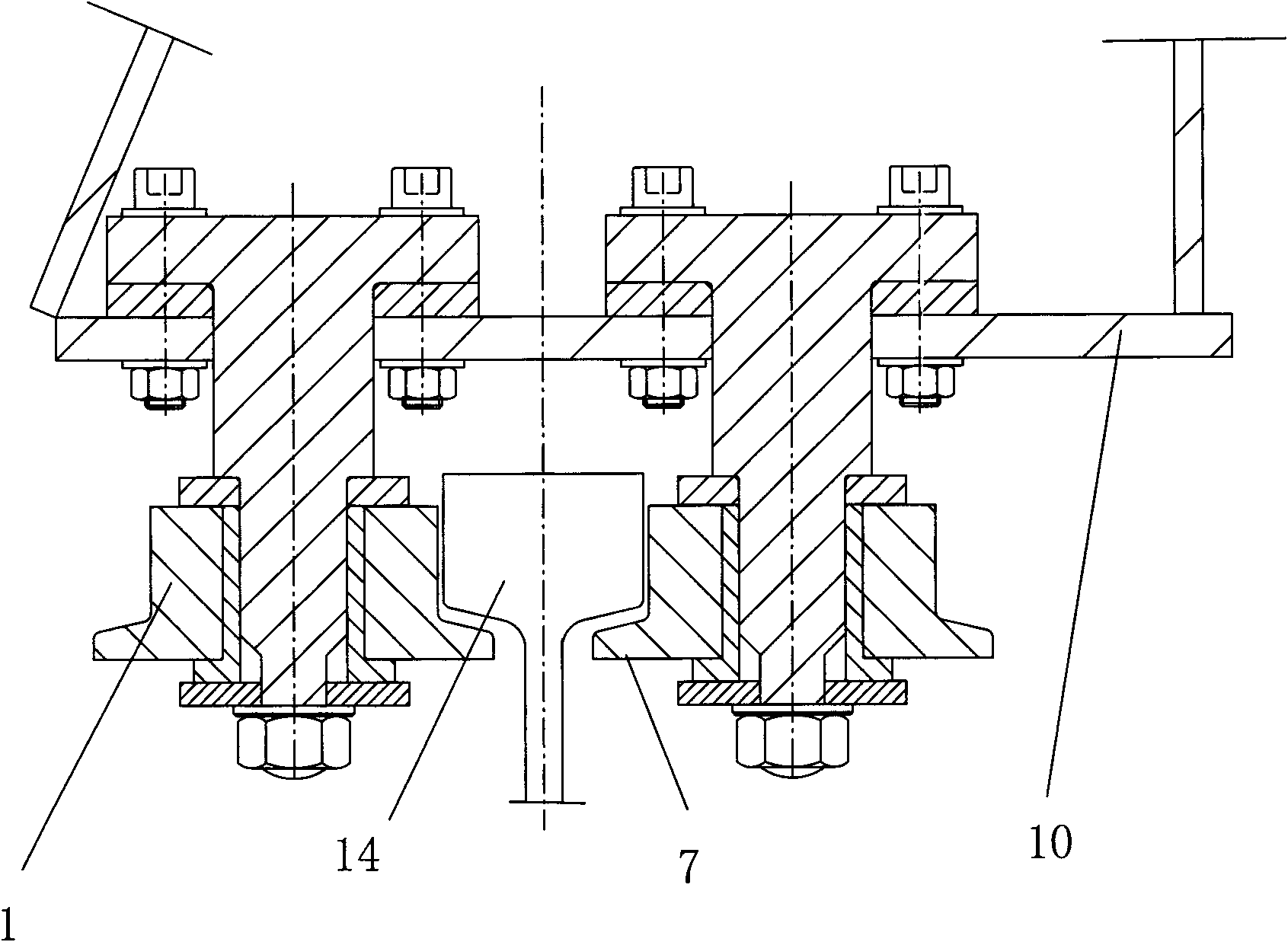

[0012] like Figure 1 to Figure 3 As shown: the guiding device is composed of a guide wheel 1, a shaft sleeve 2 and a wheel shaft 4, the wheel shaft 4 is an eccentric shaft, and the shaft center O and O1 is not on the same axis line, that is, the two are arranged in parallel and at intervals, and the gap between the guide wheel 1 and the track 14 can be adjusted by adjusting the installation holes on the wheel shaft 4 and the vehicle frame 10 . The upper shaft body 4b is fixed on the bottom frame 10 of the car body through the backing plate 11, bolts 12 and nuts 9, the guide wheel 1 is set on the lower shaft body 4a through the bushing 2, and the bottom of the lower shaft body 4a is provided with external threads. , There is a shaft shoulder between the lower shaft body 4a, 4b, the nut 5 fixes the bushing 2 on the lower shaft body 4a through the upper and lower backing plates 8, 3, the cylindrical surface of the guide wheel 1 is in contact with the side wings of the track 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com