Separation type knife library protection device for moving beam gantry machining center

A machining center and protection device technology, applied in the field of separate tool magazine protection devices, can solve problems such as instability, fewer maintenance windows for CNC machine tools, and poor automation of tool magazine sliding doors, so as to avoid impact and deformation and facilitate rapid assembly Effects of commissioning and modular production commissioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

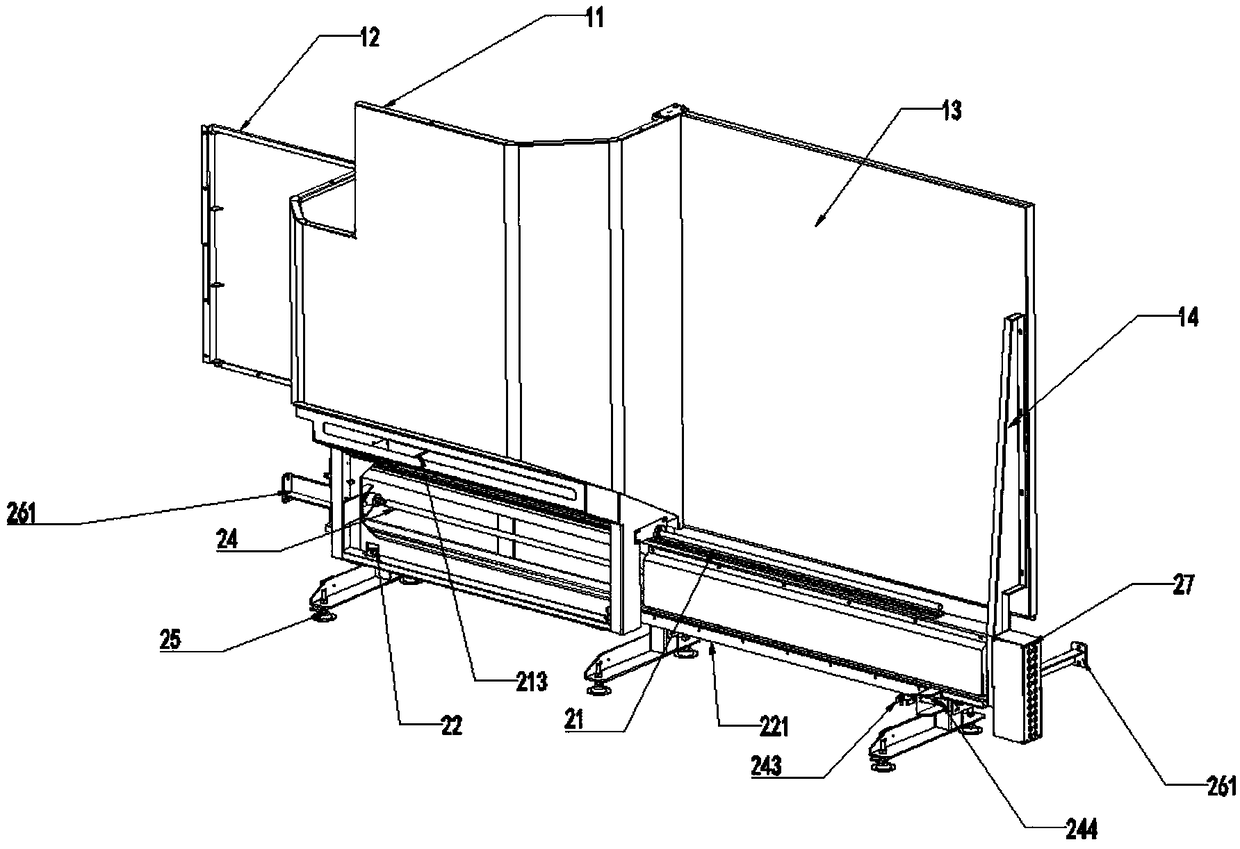

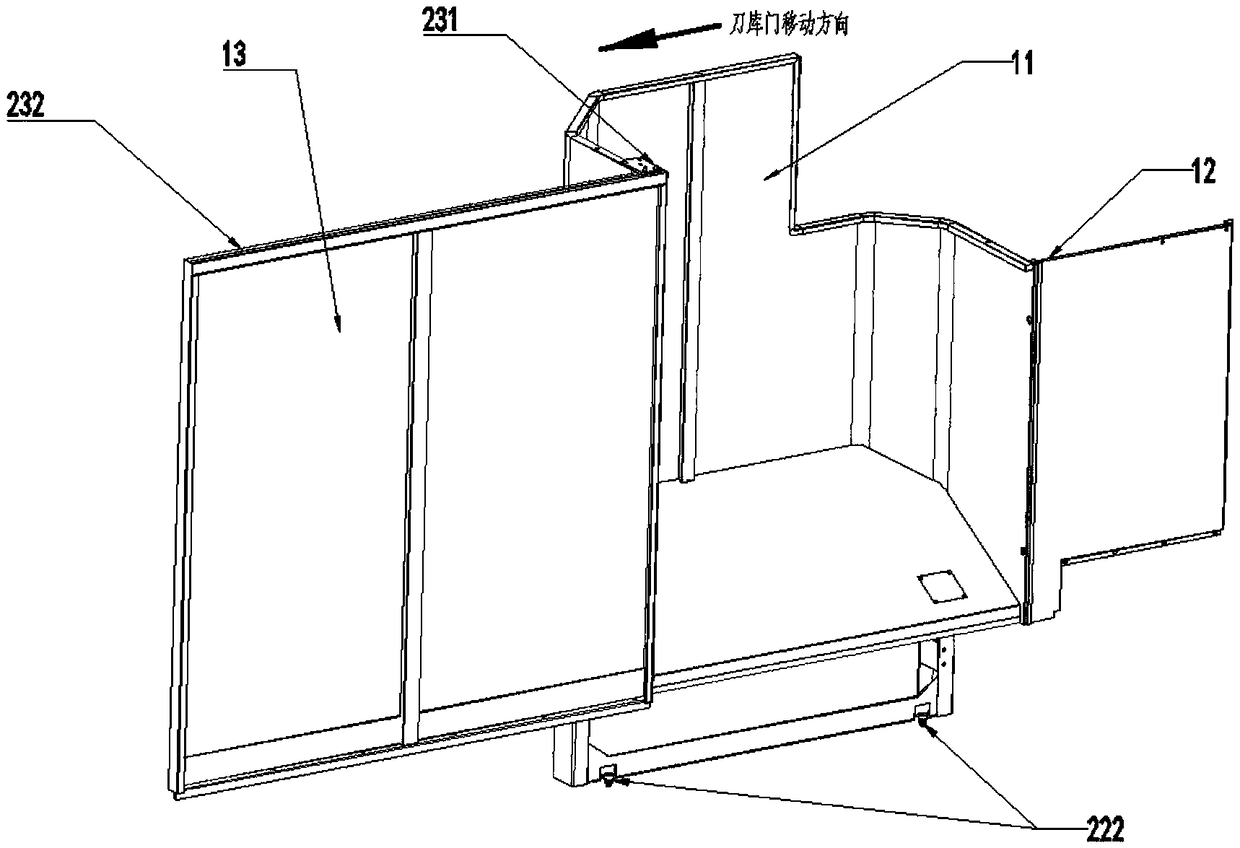

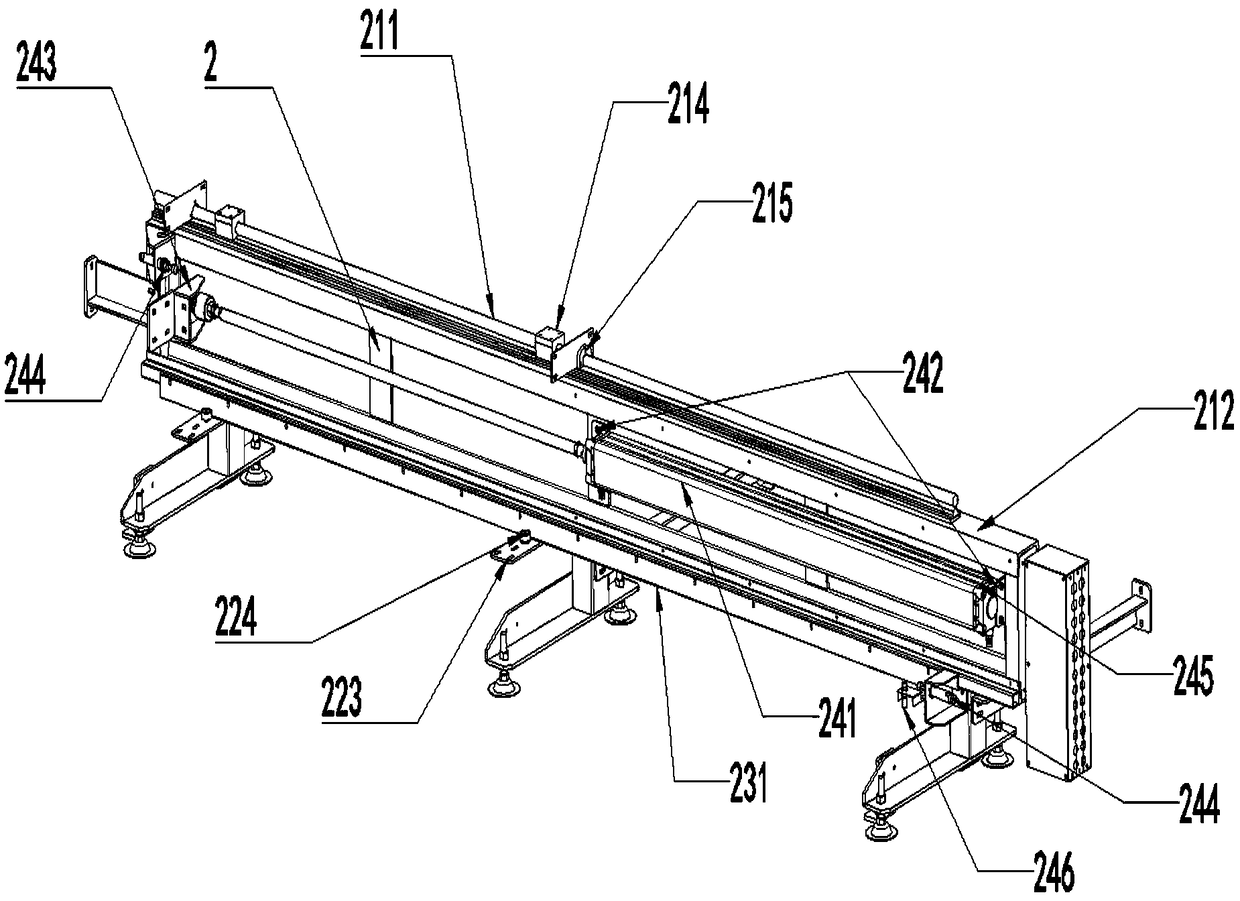

[0021] like figure 1 As shown, a separate tool magazine protection device for a moving beam gantry machining center includes a protective door for waterproof and chip prevention, and a protective door base mechanism for connecting and driving the protective door.

[0022] figure 1 It is a structural schematic diagram of the main body of the tool magazine protection device of the present invention. The figure includes the tool magazine door 11, which uses profile welded parts as the frame to improve its overall rigidity, and the chip guide surface adopts a large-slope structural design, which avoids the accumulation of iron filings during processing and facilitates the rapid return of cutting fluid. The tool magazine protective cover 13 is directly fixed on the protective chip removal groove of the machine tool to play the role of auxiliary chip prevention. In order to strengthen its rigidity, an auxiliary reinforced support 14 is added to its end face. A column protective co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com