Self locking type worm gear-worm screw-threaded shaft elevator

A screw lifter and worm gear technology, applied in the field of lifts, can solve the problems of poor self-locking capacity and low load-bearing capacity, and achieve the effect of reasonable structure, strong load-bearing capacity, and good self-locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

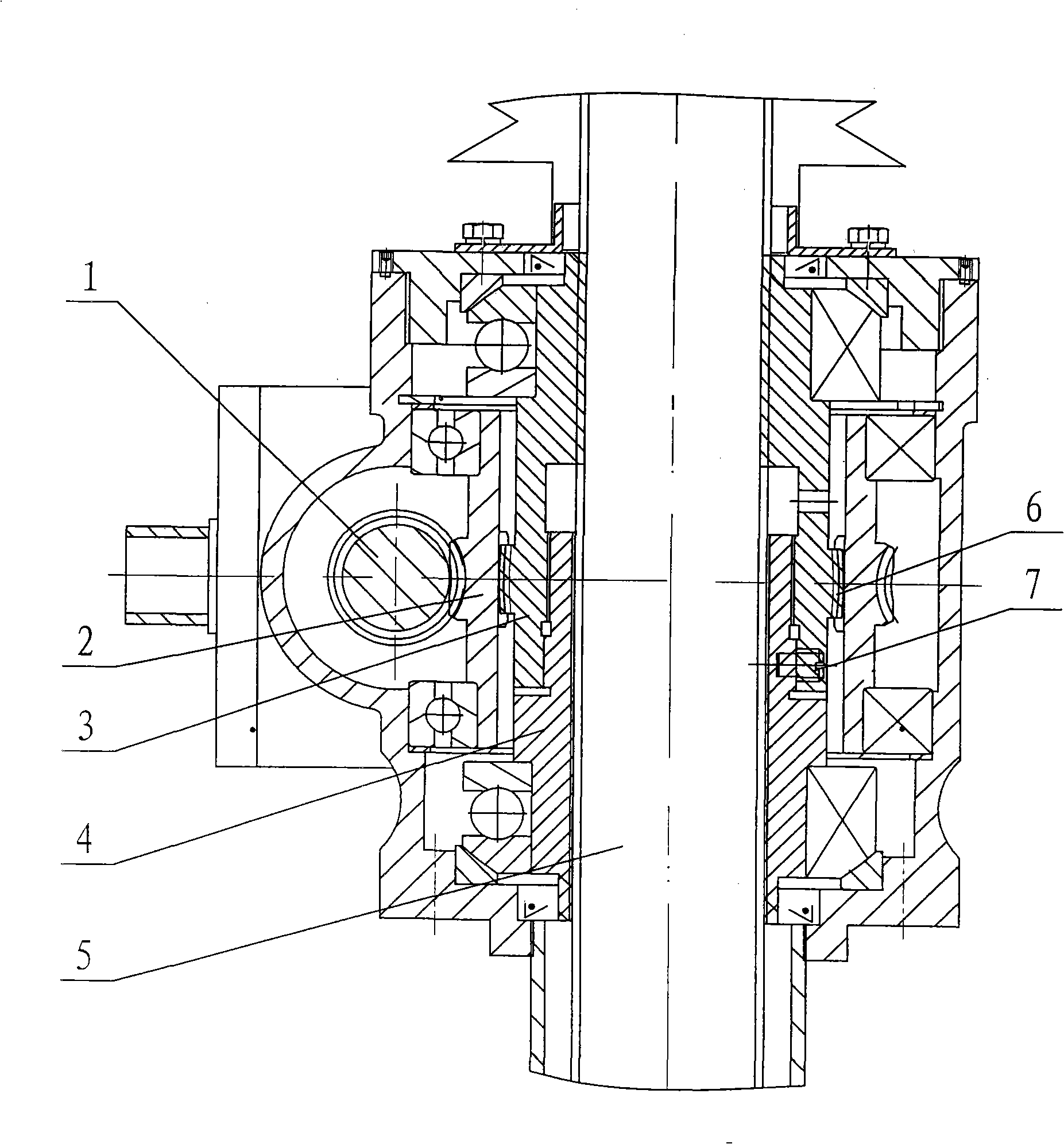

[0016] figure 1 A self-locking worm gear screw lift shown, including a worm 1, a worm wheel 2, a nut, a lead screw 5, and a drum-shaped tooth 6, the worm 1 meshes with the worm wheel 2, and the worm wheel 2 meshes with the nut through the drum-shaped tooth 6, The nut is screwed with the lead screw. The nut is a double nut structure, including the nut concave part 3 and the nut convex part 4 that are screwed together. The screwed part of the nut concave part and the nut convex part is smooth connection or threaded connection or such as figure 1 In the connection structure of the combination of smooth surface and screw thread shown, the screwed part of the nut concave part and the nut convex part is riveted by the stop screw 7, and the recessed depth of the nut concave part is greater than the protruding height of the nut convex part.

[0017] In the design of the worm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com