Single-beam overhead crane

A single girder and cart technology, applied in the direction of walking bridge cranes, load suspension components, safety devices, etc., can solve problems such as safety accidents, reduce costs, and affect running stability, so as to improve product performance and reduce safety. Accidents, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the technical principle and working process of the embodiments of the present invention, the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

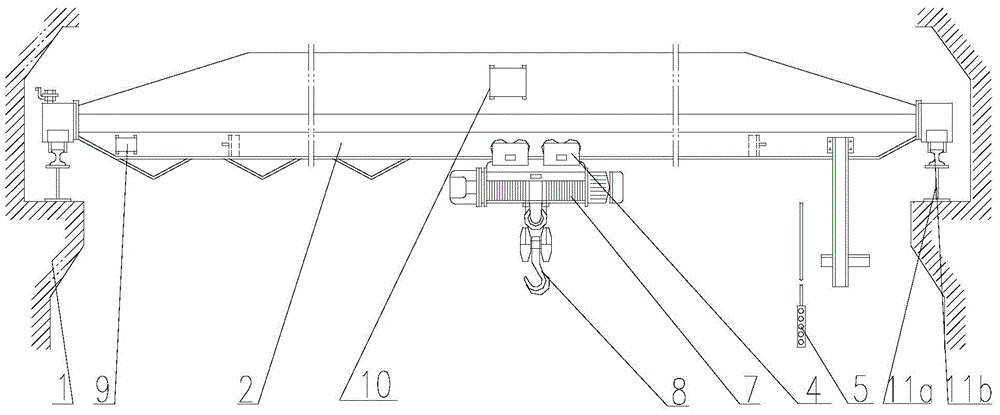

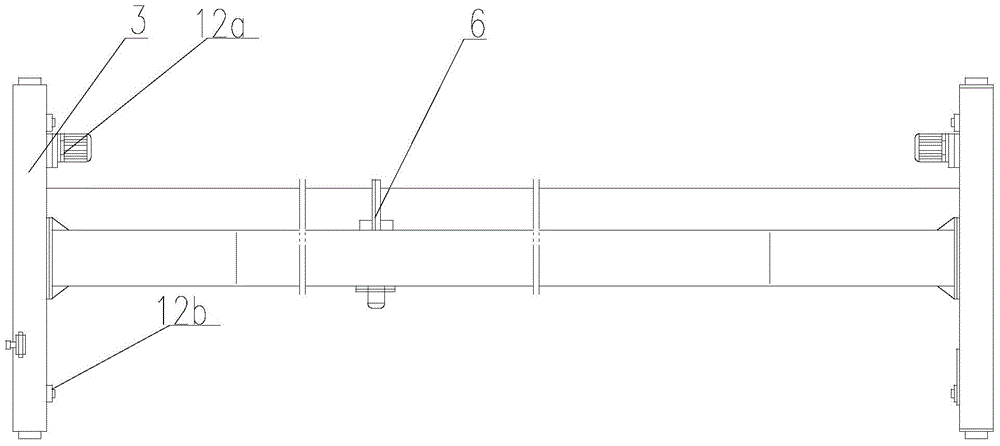

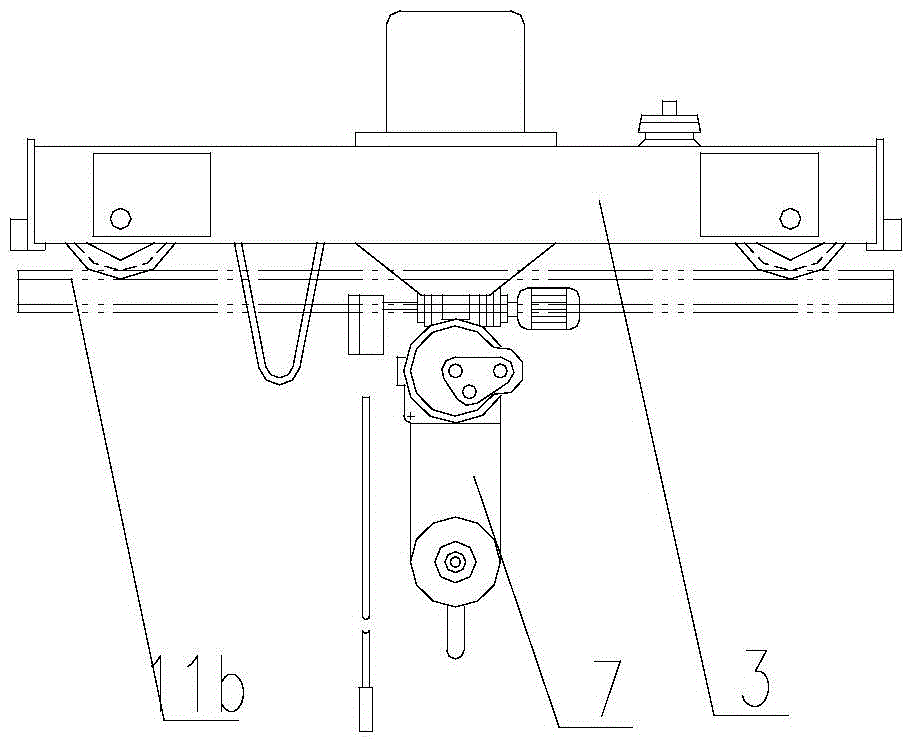

[0027] see also Figure 1a-Figure 1c , shows the overall structure of the single beam crane of the present invention. Such as Figure 1a-Figure 1c In the single-girder crane shown (hereinafter referred to as the crane), the middle main beam 2 and the end beams 3 on both sides are fixedly connected to form a beam frame, and the end beam track 11b is fixed on the steel structure 1 of the factory building by the end beam track support 11a. Driven by the cart (including the active train set 12a and the passive train set 12b), it can run on the end beam track 11b, the electric hoist 7 runs on the main beam track with the trolley 4, and the crane is controlled by the remote control 5 to move in three directions , the hook 8 can easily...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com