Electronic-magnetic-stirring-based oil-gas separation device

A magnetic stirring and separation device technology, applied in material separation, measuring device, separation method, etc., can solve the problems of post-processing of faulty gas, inability to meet the problems of good stability of online monitoring system, long life and maintenance-free, etc., to avoid pollution, Low cost and long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

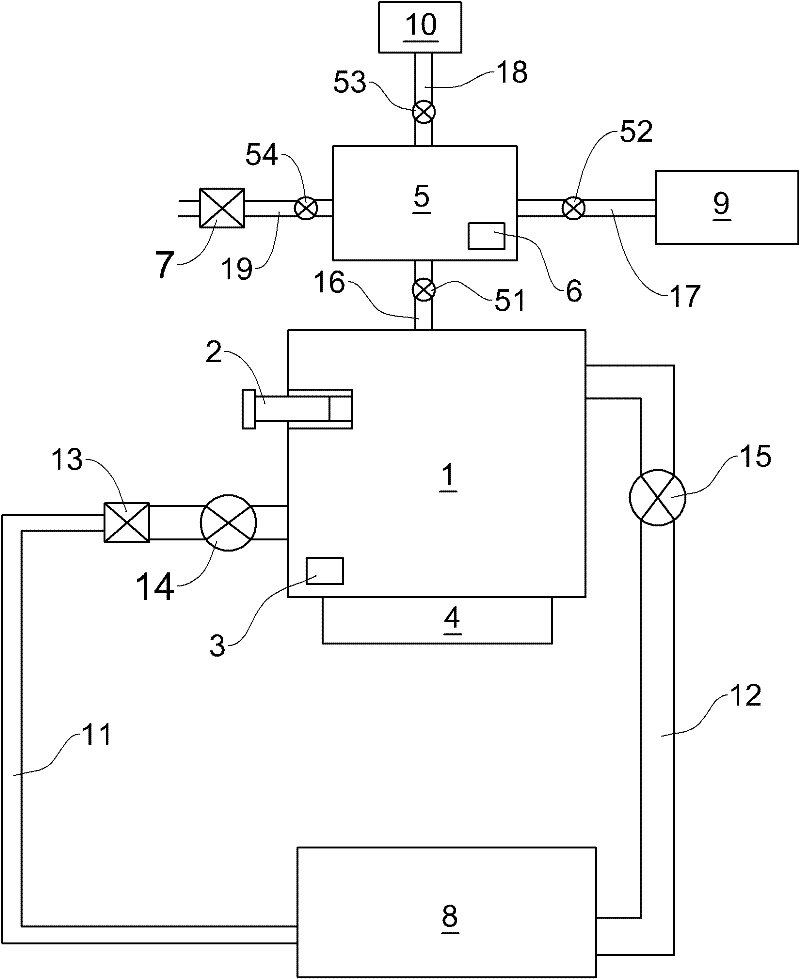

[0019] Such as figure 1 As shown, an oil-gas separation device based on electronic magnetic stirring of the present invention includes an oil-gas separation chamber 1, a stepping motor 2, an oil temperature control unit 3, an electronic magnetic stirrer 4, a cold trap 5, etc., and the cold trap 5 passes through the The inlet pipeline 16 is connected to the oil-gas separation chamber 1, connected to the gas detection unit 9 through the gas outlet pipeline 17, connected to the condensation chamber pressurization unit 10 through the pressurization pipeline 18, and connected to the condensation chamber emptying realization unit through the exhaust pipeline 19 7.

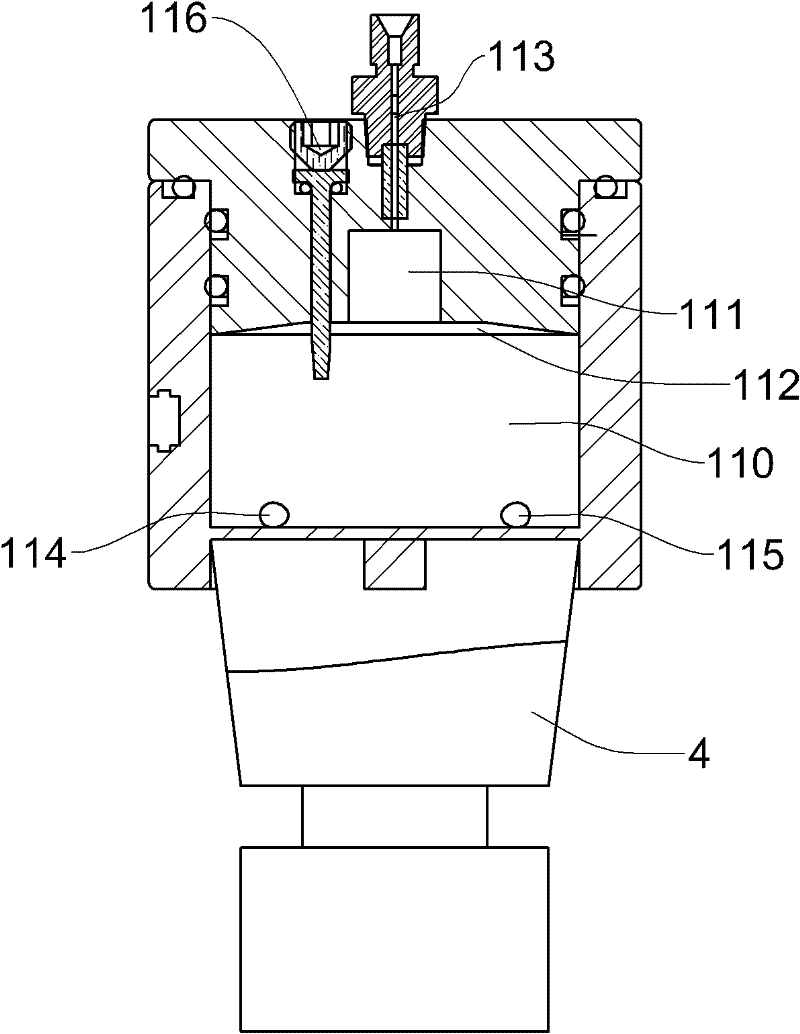

[0020] see figure 2 , the inside of the oil-gas separation chamber 1 has an oil chamber 110 and an air chamber 111, and an oil surface conical space 112 in the shape of a truncated cone is formed between the oil chamber 110 and the air chamber 111 to prevent the oil from entering the cold trap 5 due to equipment inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com