Power-transformer overall vacuumizing device

A technology of vacuum pumping device and power transformer, applied in transformer/inductor cooling, switchgear, electrical components, etc., can solve the problems of low vacuum degree of transformer oil conservator, reduction of internal insulation of transformer, expansion and rupture of capsule 4', etc. Achieve the effect of preventing air from entering the inside of the transformer, reducing the accident rate, and reducing manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

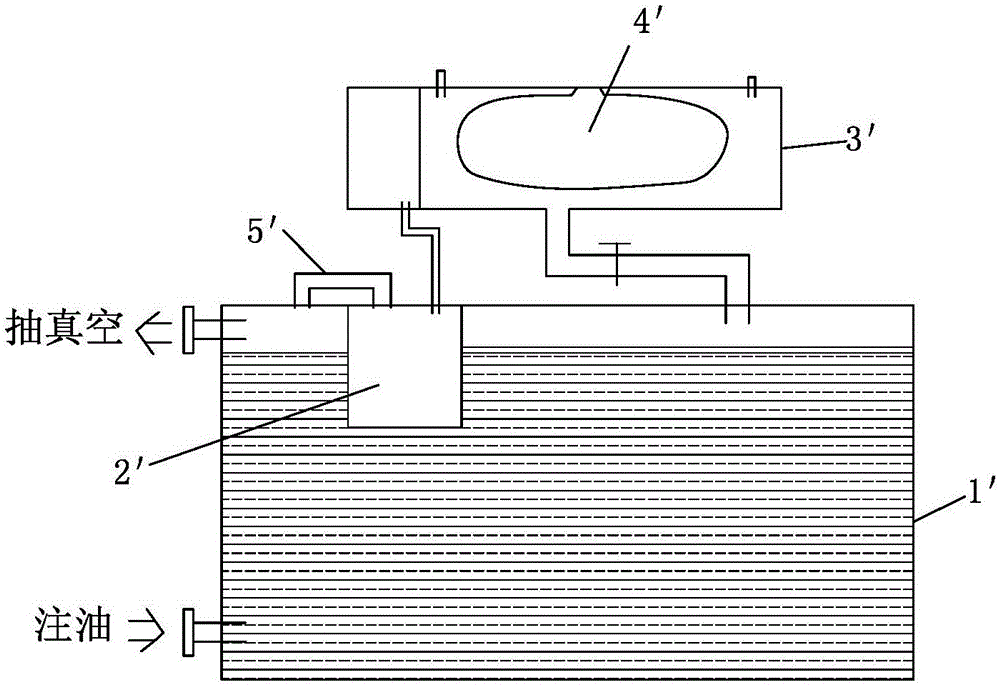

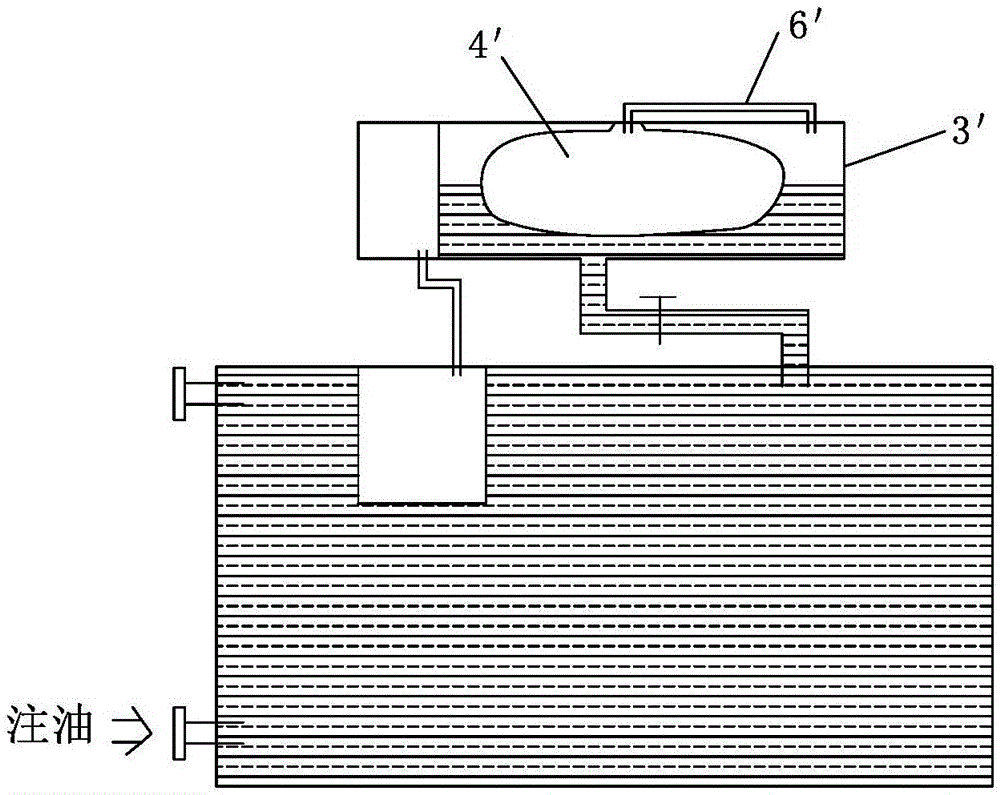

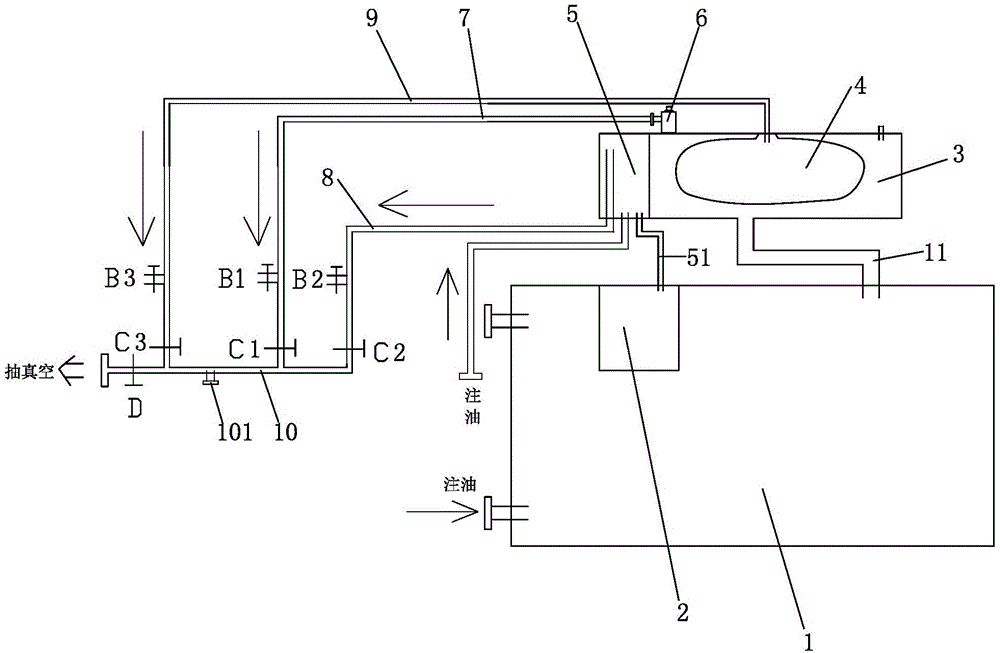

[0031] Examples, see image 3 , Figure 4 As shown, an overall vacuum pumping device for a power transformer of the present invention includes a transformer body 1, a body oil conservator 3, a capsule 4, and an on-load oil conservator 5. The transformer body 1 is connected to the body oil conservator 3 through a connecting pipe 11. The capsule 4 is arranged in the oil conservator 3 of the body, and the on-load oil conservator 5 communicates with the oil chamber 2 of the on-load tap changer in the transformer body 1 through a connecting pipe 51 . A control assembly 6 is installed at the exhaust port 31 of the oil conservator 3 of the body. The control assembly 6 is used to replace the vent plug of the oil conservator 3 of the body in a vacuum state so as to block the exhaust of the oil conservator 3 of the body. The air port 31, the control assembly 6 has a chamber 66 connected to the oil conservator 3 of the body before the vent plug is lowered, and the chamber 66 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com