Electronic control oil sprayer for injection valve

An electronically controlled fuel injection and fuel injector technology, which is applied to fuel injection devices, machines/engines, charging systems, etc., can solve problems such as difficult processing and difficulty in processing throttle cone holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples.

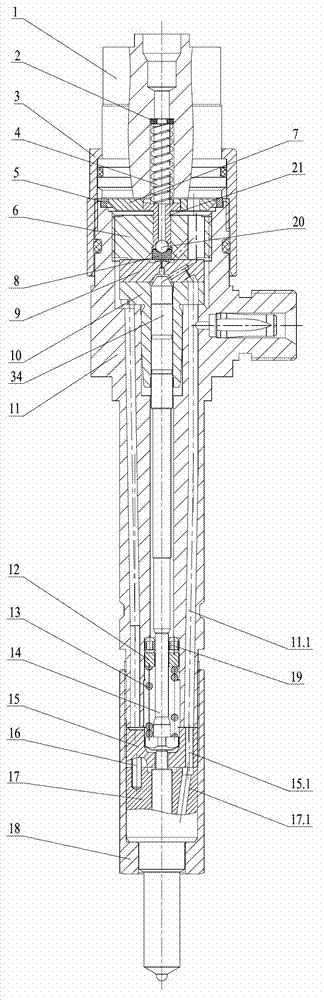

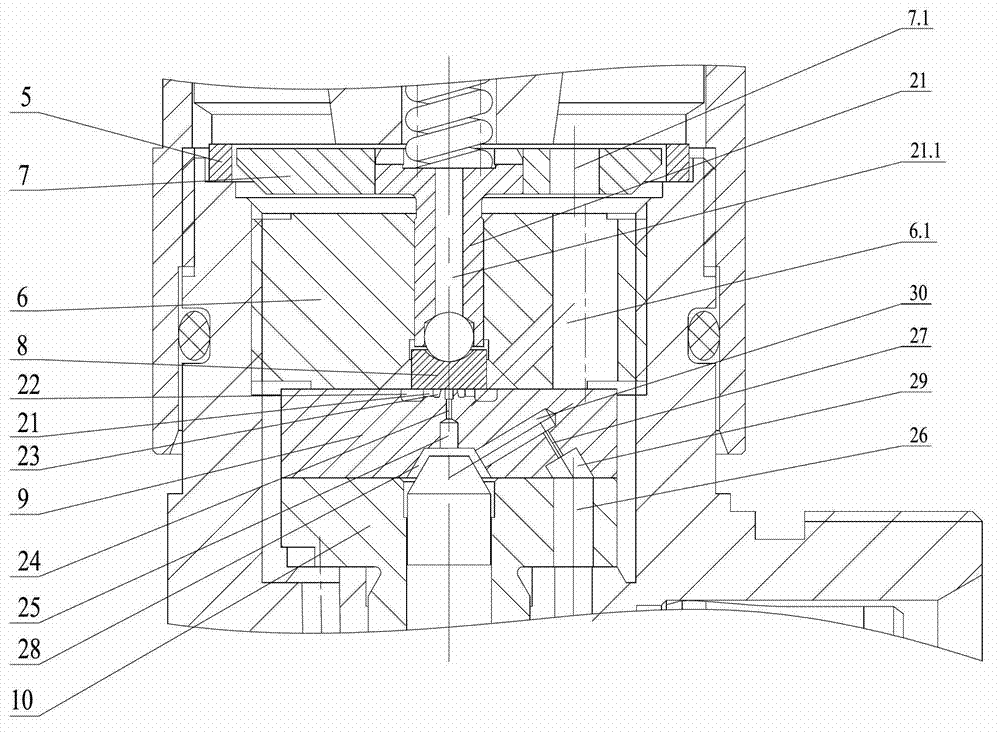

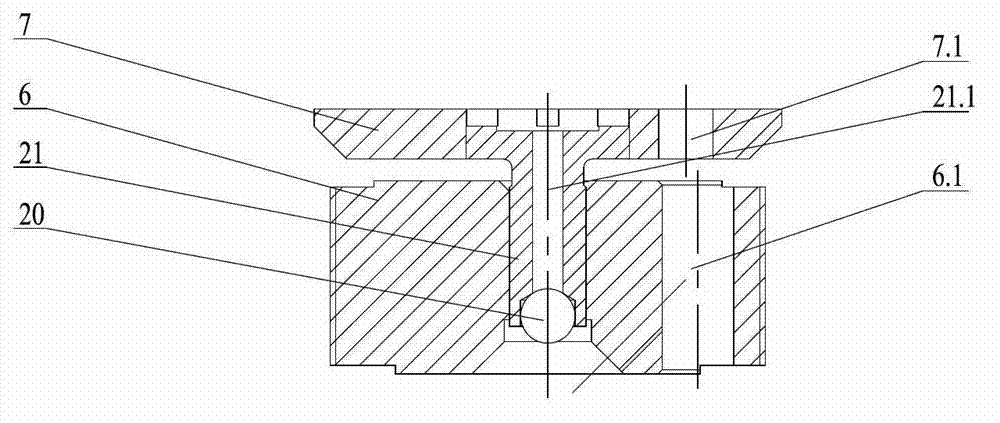

[0017] As shown in the figure, the electronically controlled fuel injector of the injection valve has a fuel injector body oil hole 11.1 in the fuel injector body 11, and the fuel injector body oil hole 11.1 and the oil inlet port on the fuel injector body 11 Connected, the injector body 11 is provided with a lining ring 5 and a pilot valve seat 6, the pilot valve seat 6 is located below the lining ring 5, and the pilot valve seat 6 is provided with a pilot valve seat oil hole 6.1 and an armature rod guide hole , a throttle orifice 9 is provided below the guide valve seat 6, and a control chamber 28, an oil inlet orifice 27, a throttle orifice oil inlet 29, and a connecting oil hole 30 are provided on the throttle orifice 9. , the oil return orifice 24 and the oil hole 25 under the orifice plate, the aperture of the oil inlet orifice 27 is smaller than the aperture of the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com