Lubricating oil way of automobile engine

A technology of automobile engine and lubricating oil circuit, applied in the direction of pressure lubricating safety device, etc., can solve the problems of hydraulic parts failure, increased bearing wear, etc., to avoid backflow, improve cost performance, and ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

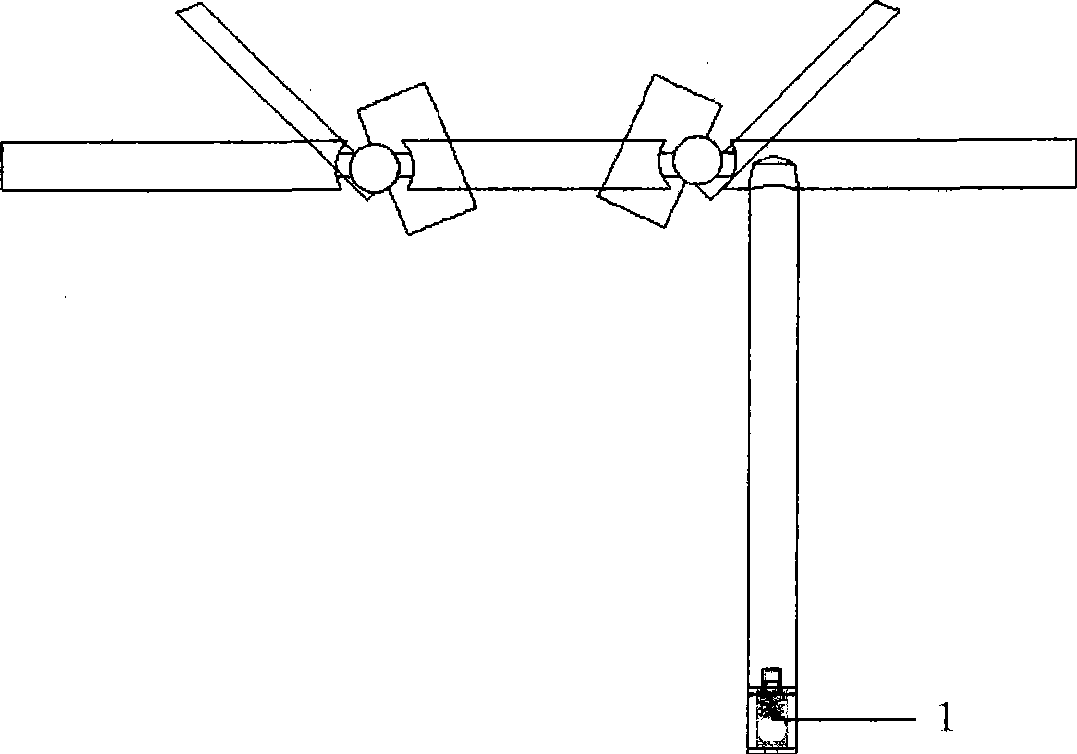

[0013] Such as figure 1 As shown, a check valve 1 is provided at the entrance where the main oil passage of the cylinder block enters the main oil passage of the cylinder head.

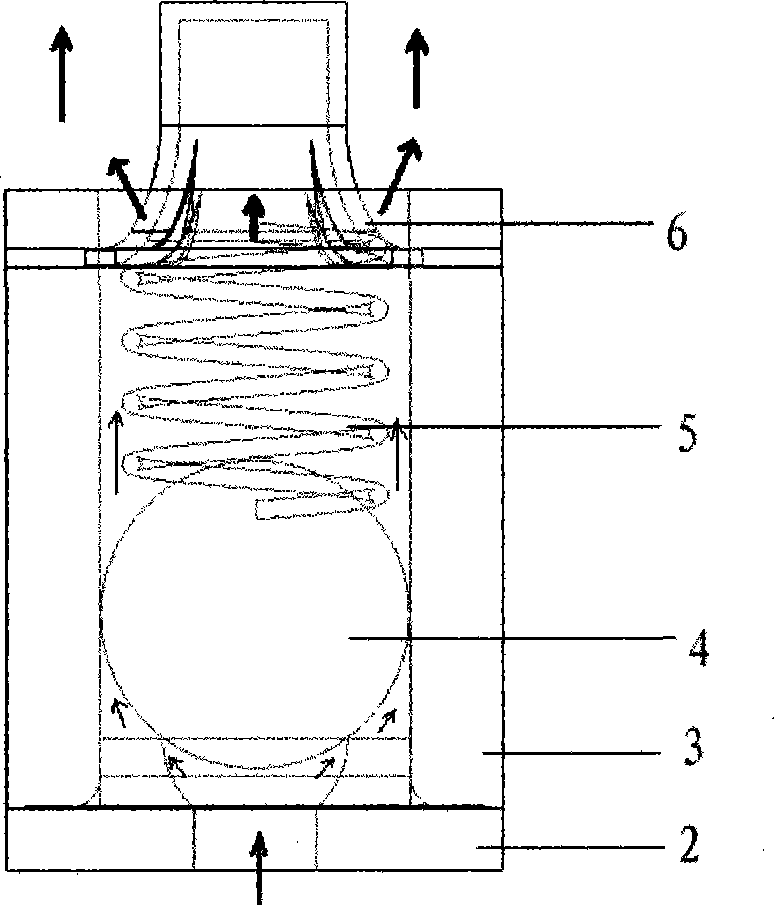

[0014] Such as figure 2 As shown, the check valve has a valve cylinder body 3, a valve seat body 2, a valve ball 4, and a spring 5. The valve cylinder body 3 is connected to the valve seat body 2, and the valve seat body has an oil inlet. Inside the spool body, a valve ball 4 is set corresponding to the position of the oil inlet. The spring is installed in the spring seat 6, and the side of the spring seat has an oil outlet.

[0015] The one-way valve is affected by three forces: the oil pressure on the upper side of the cylinder head, the elastic force of the spring, and the gravity of the valve ball itself. When the engine is not working, the influence of these three forces causes the valve ball to cling to the valve seat body to close the valve. When the engine starts, the oil pump pumps out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com