Self-sealing oil gun for oil gas recovery

A fuel gun, oil and gas technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of weight reduction, difficulty and cost, high cost, etc., and achieve the effects of weight reduction, safety reliability and stability, and high flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

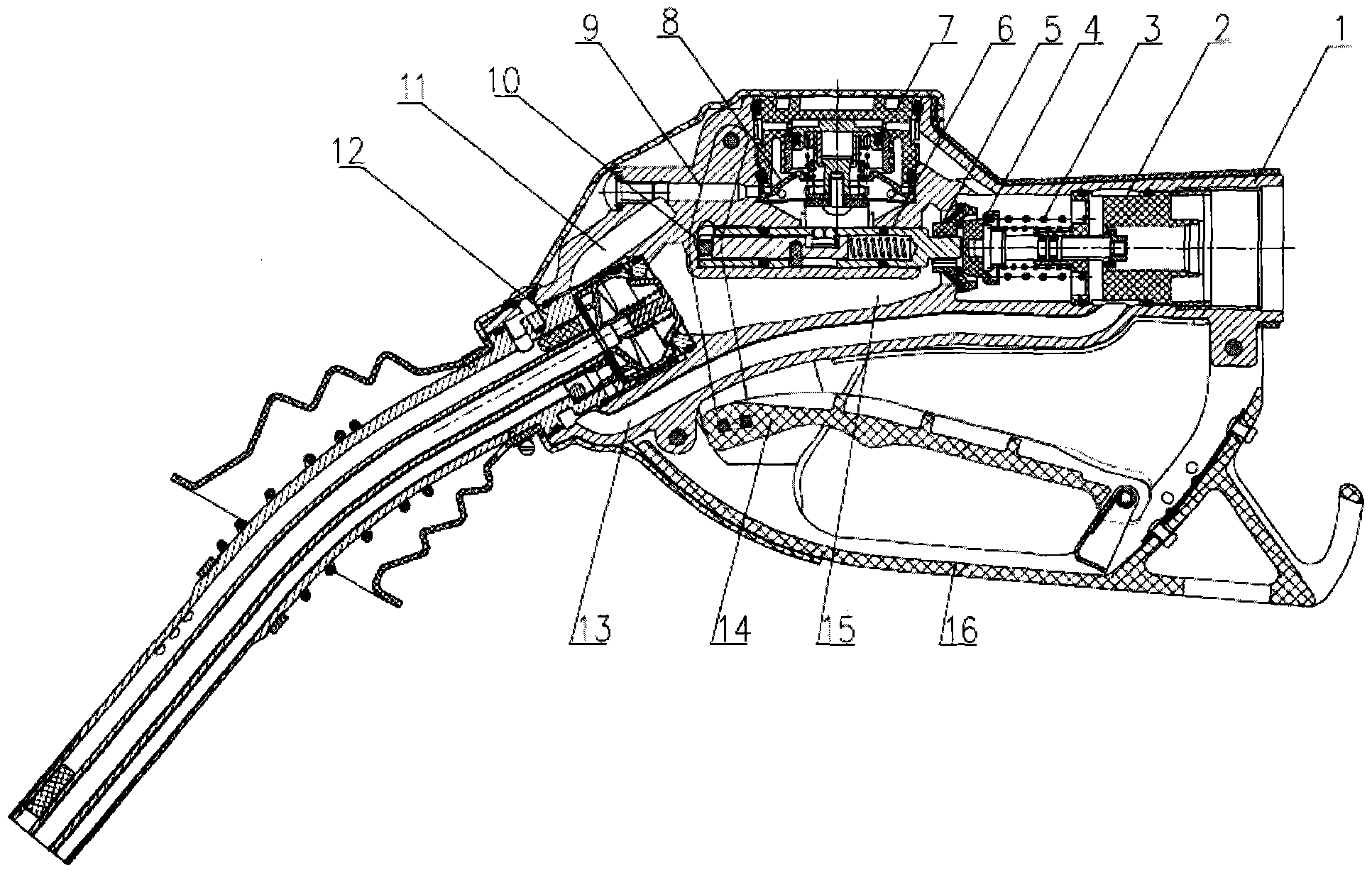

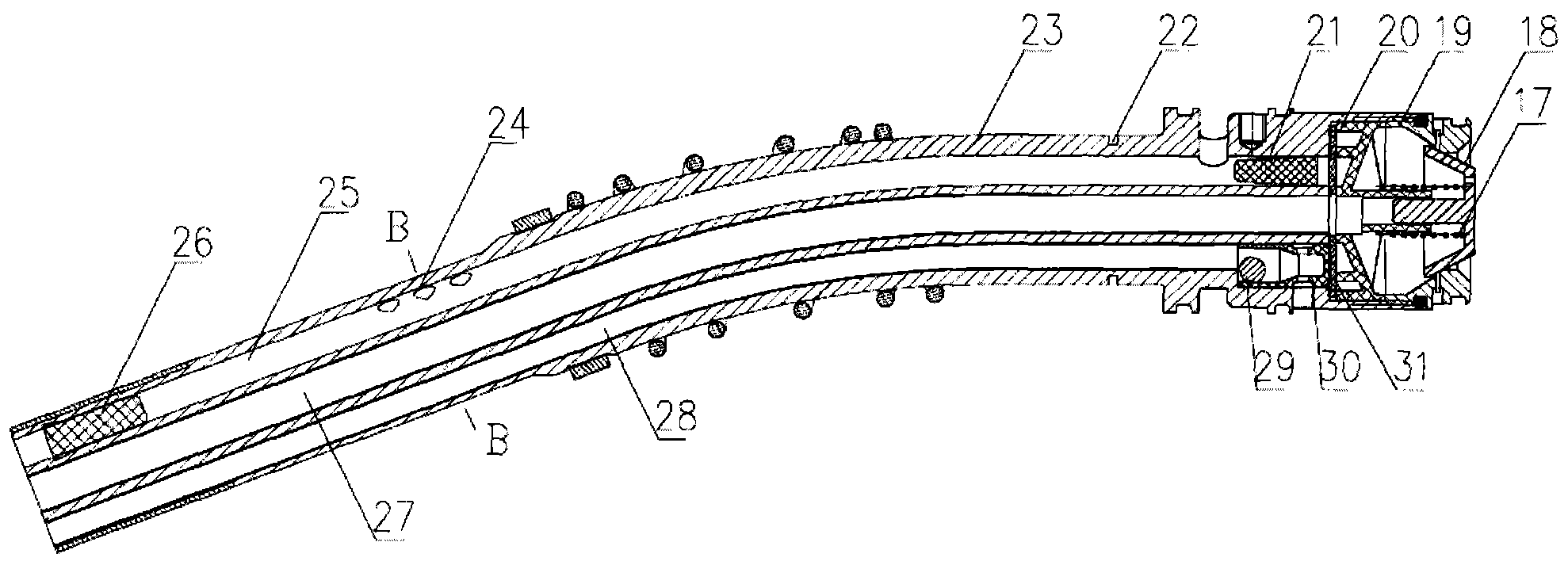

[0018] Below in conjunction with accompanying drawing, structural principle and implementation mode of the present invention are set forth in detail:

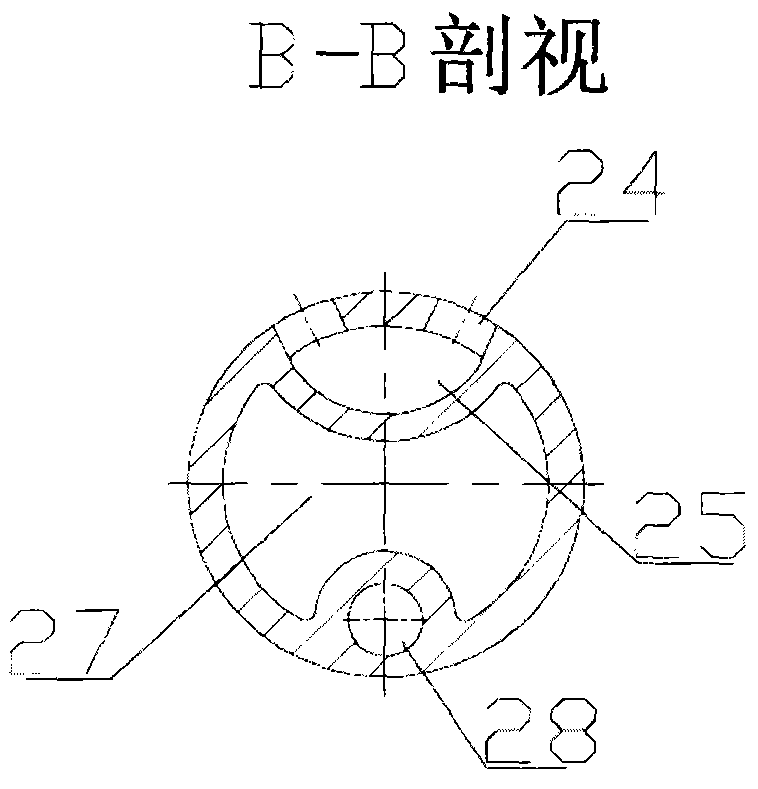

[0019] Such as figure 1 In the oil and gas recovery self-styled refueling gun shown, an independent oil and gas recovery cavity 13 is integrated in the lower part of the oil channel cavity 15 of the gun body, which forms a complete return air channel by communicating with the oil and gas separation assembly 2 and the barrel assembly 12, and connects with the oil channel phase separation. The inside of the gun barrel 23 integrates an oil gas recovery passage 25, an air supply passage 28 and an oil output passage 27, such as figure 2 and image 3 As shown, these three passages are formed by one-time extrusion. The oil and gas recovery passage plug A21 and the oil and gas recovery passage plug B26 respectively seal the two ends of the oil and gas recovery passage. The small hole 24 enters the oil and gas recovery passage 25, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com