The method is suitable for assembly process visualization of large-scale marine oil and gas core module equipment

A core module and assembly process technology, applied in the direction of design optimization/simulation, configuration CAD, CAD numerical modeling, etc., can solve the problems of slow mastery of new product assembly sequence, large number of scrapped parts, and invalid assembly path, etc., to achieve The effect of ensuring construction safety and assembly efficiency, improving assembly safety, and reducing personnel risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

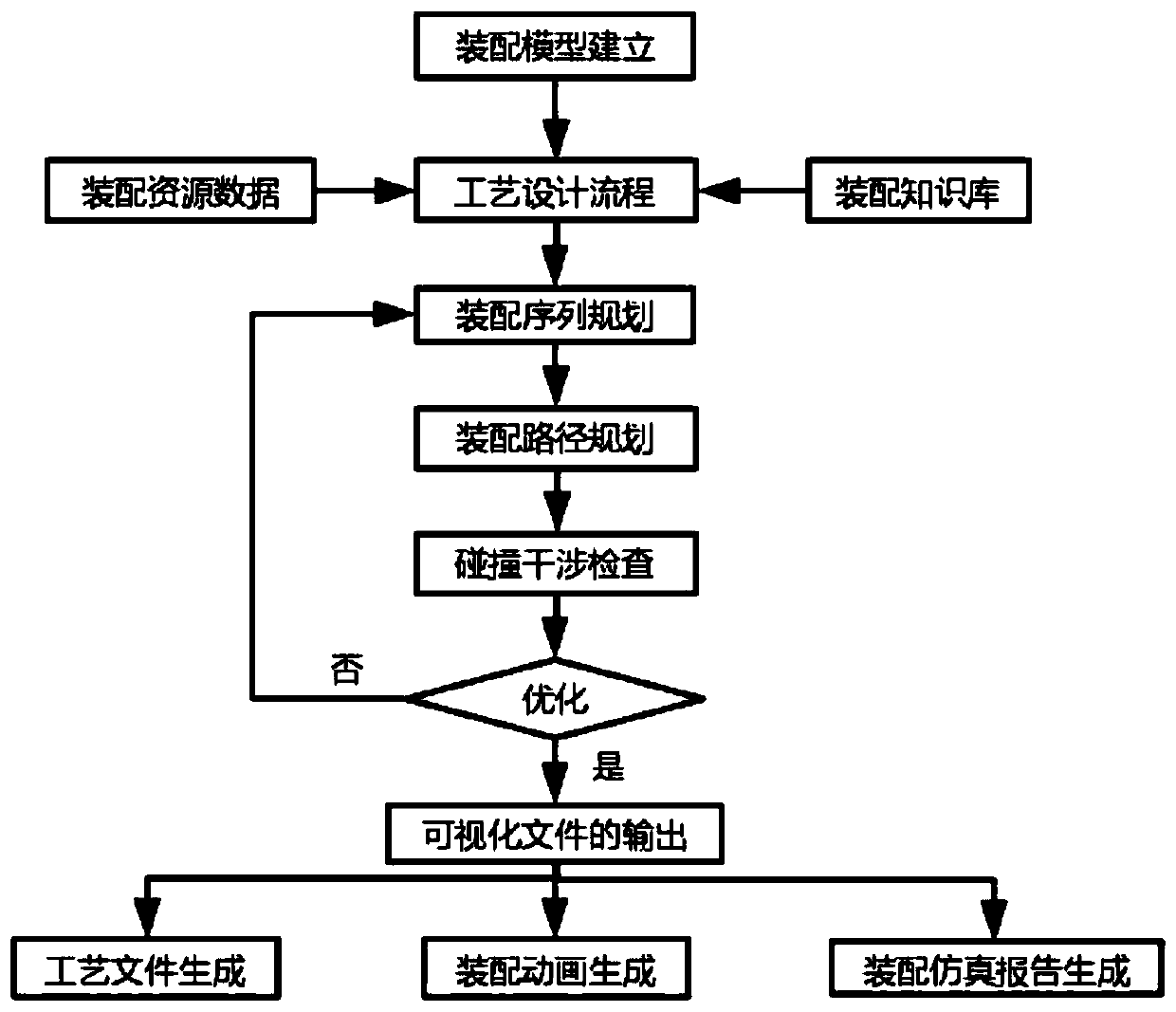

[0025] as attached figure 1 A visualization method for assembly process of the present invention applicable to large-scale offshore oil and gas core module equipment includes the following steps:

[0026] Step 1. Use a hierarchical model to represent the assembly information model of the equipment. The specific process is:

[0027] The first step is to carry out hierarchical planning for the assembly, and to reflect the basic assembly information of each part of the equipment (including geometric properties, physical properties, engineering properties, etc.), the hierarchical information of the equipment, and the constraint information between parts in the form of an assembly tree. Write the process information such as assembly process, assembly task and assembly action into the hierarchical information of the equipment, set the hierarchical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com