Pressure stabilization compensation device and energy accumulator detection system with same

A compensating device and voltage stabilization technology, applied in the direction of fluid pressure actuating device, fluid pressure actuating system testing, mechanical equipment, etc. The effect of hydraulic shock, absorption of system pulsation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

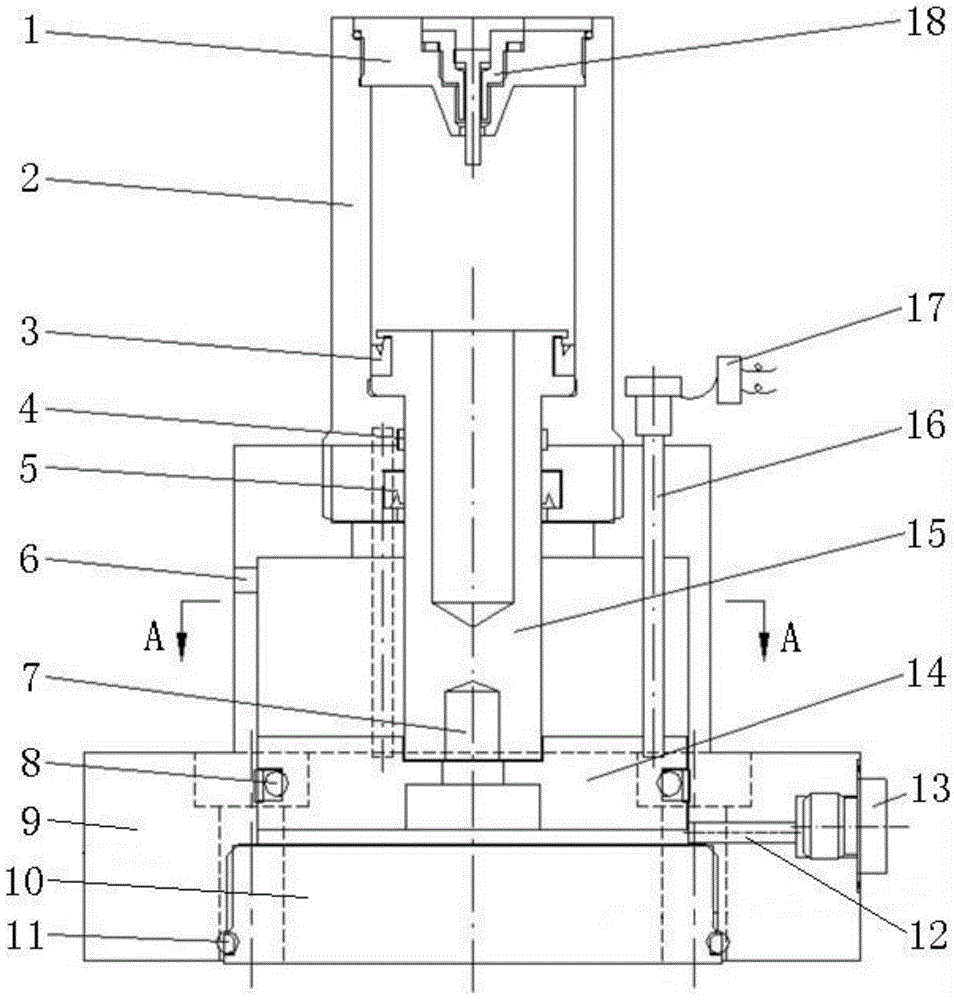

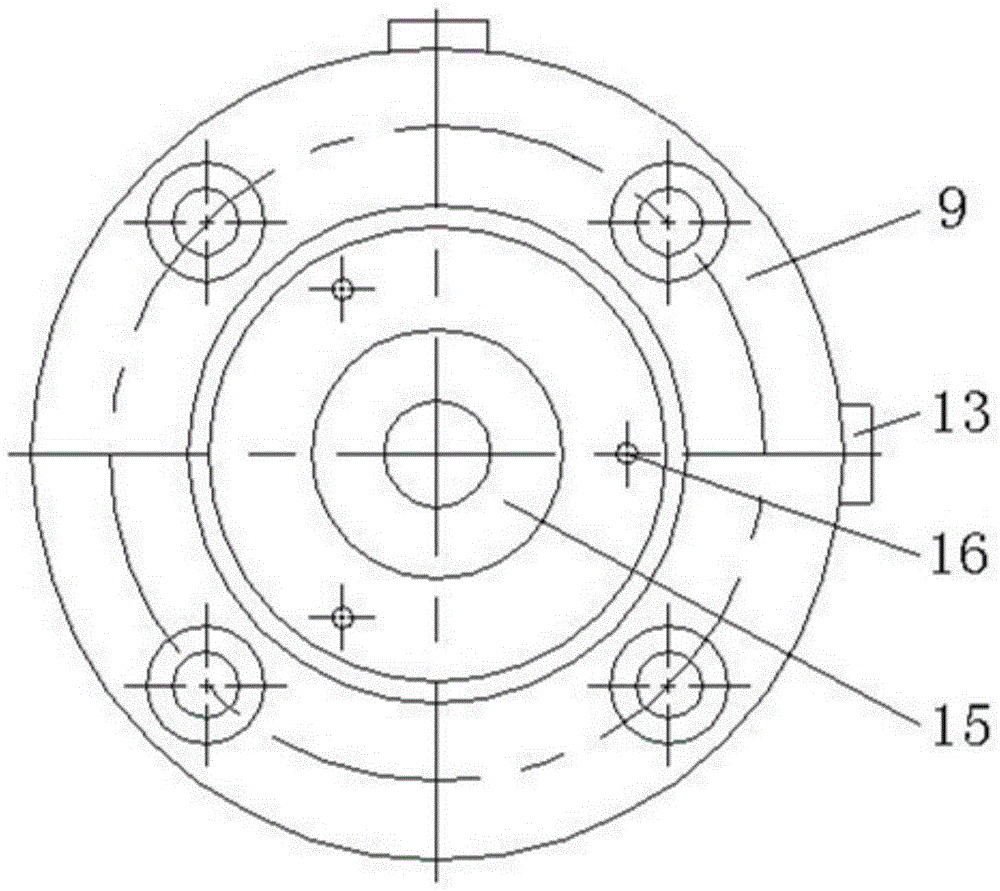

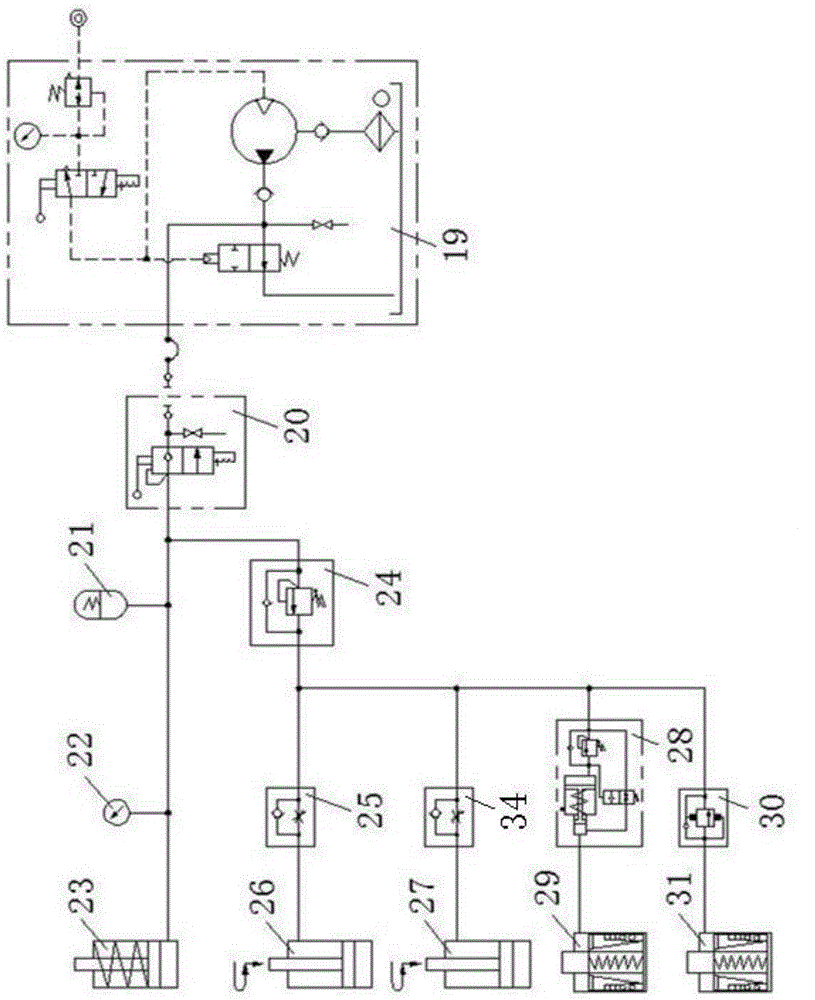

[0018] Such as figure 1 , figure 2 As shown, the voltage stabilizing compensation device includes a nitrogen gas spring, a master cylinder 9, a master cylinder end cover 10, a master cylinder piston body 14 and a gauge needle 16; the nitrogen gas spring includes a nitrogen cylinder end cover 1, a nitrogen cylinder body 2 and a nitrogen cylinder piston 15 , the outer wall of the nitrogen cylinder block 2 is provided with a scale, the nitrogen cylinder piston 15 is a cavity structure, the piston body of the nitrogen cylinder piston 15 cooperates with the inner chamber clearance of the nitrogen cylinder body 2 and is sealed by the nitrogen cylinder piston body oil seal 3, The piston rod of the nitrogen cylinder piston 15 stretches out from the bottom of the nitrogen cylinder body 2 and fits in a gap with the nitrogen cylinder body 2 and is sealed by the nitrogen cylinder piston rod oil seal 5 . A guide ring 4 is arranged between them, and the top of the nitrogen cylinder body ...

Embodiment 2

[0021] Such as figure 1 , figure 2As shown, the voltage stabilizing compensation device includes a nitrogen gas spring, a master cylinder 9, a master cylinder end cover 10, a master cylinder piston body 14 and a gauge needle 16; the nitrogen gas spring includes a nitrogen cylinder end cover 1, a nitrogen cylinder body 2 and a nitrogen cylinder piston 15 , the outer wall of the nitrogen cylinder block 2 is provided with a scale, the nitrogen cylinder piston 15 is a cavity structure, the piston body of the nitrogen cylinder piston 15 cooperates with the inner chamber clearance of the nitrogen cylinder body 2 and is sealed by the nitrogen cylinder piston body oil seal 3, The piston rod of the nitrogen cylinder piston 15 stretches out from the bottom of the nitrogen cylinder body 2 and fits in a gap with the nitrogen cylinder body 2 and is sealed by the nitrogen cylinder piston rod oil seal 5 . A guide ring 4 is arranged between them, and the top of the nitrogen cylinder body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com