Method for preparing boric acid ester automobile braking fluid with high performance

A technology of automobile brakes and boric acid esters, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of unconsidered boric acid hydrolysis stability, insufficient consideration of corrosion resistance, low temperature viscosity increase, etc., to achieve optimization Brake fluid performance, good anti-corrosion effect, stable color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

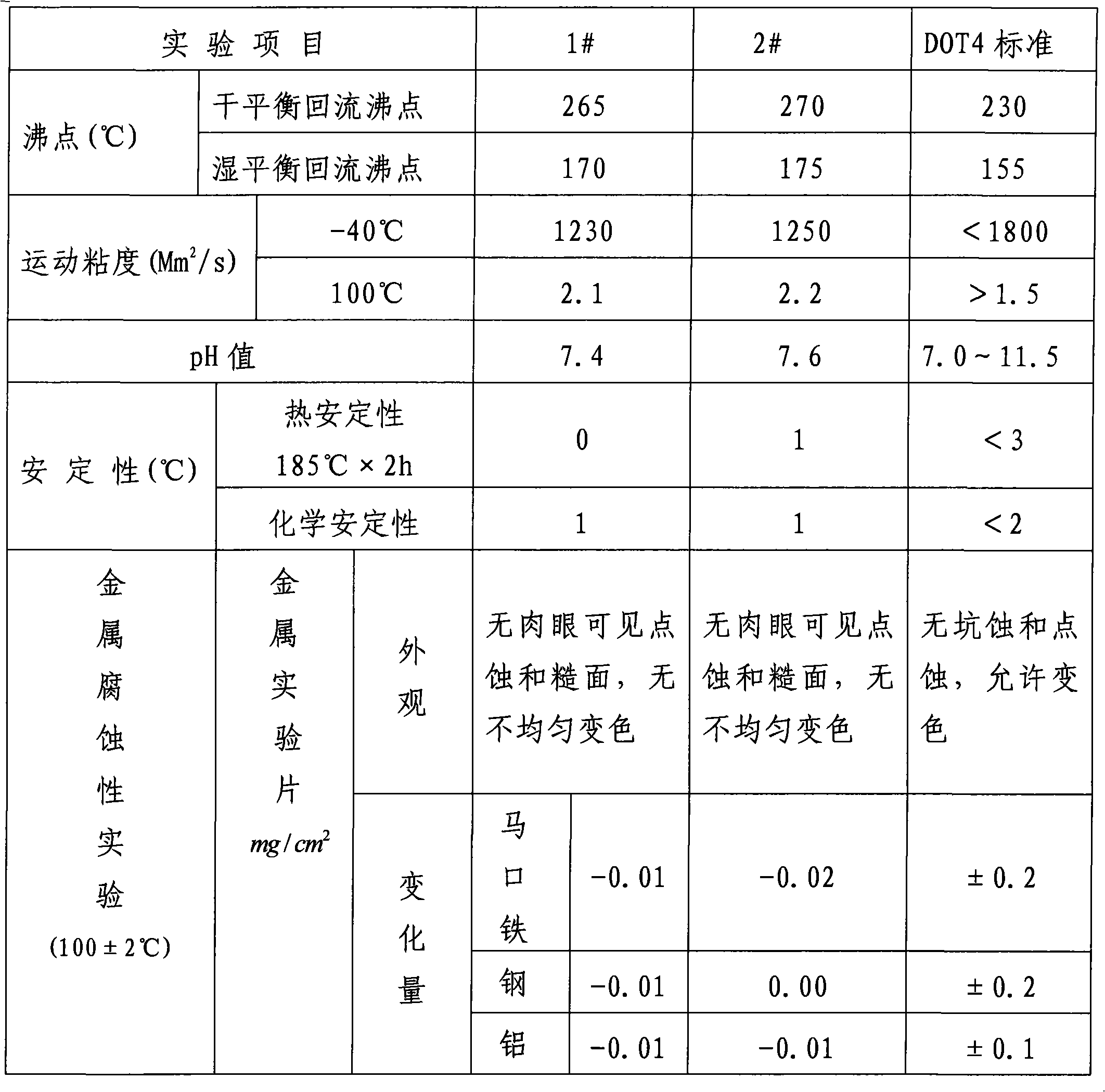

Embodiment 1

[0025] Take 60g of propanol, 232g of propylene oxide, and 0.6g of sodium hydroxide into the autoclave, blow nitrogen gas, keep the pressure in the autoclave at 0.4-0.5Mpa, set the temperature of the autoclave at 150°C, heat and stir, and the pressure will reach the highest value with time , and then the pressure drops rapidly. When the pressure drops to about 0.5Mpa, the polymerization is completed. After standing for 1 hour, add lactic acid to adjust the pH value to 7-8, and obtain a clear, transparent, light yellow liquid polypropanol propyl ether;

[0026] Take 64g of methanol, 580g of propylene oxide, and 0.64g of sodium hydroxide and put them into the autoclave, set the temperature of the kettle to 165°C, the method is the same as that of polypropanol propyl ether, and the product obtained is polymethanol propyl ether.

[0027] Take 221g of polypropanol propyl ether and 6.0g of boric acid into a three-neck flask, add the enhanced distillation agent zeolite molecular sieve,...

Embodiment 2

[0031] Take 40g of propanol, 200g of propylene oxide, and 0.40g of sodium hydroxide into the autoclave, blow nitrogen gas, keep the pressure in the autoclave at 0.4-0.5Mpa, set the temperature of the autoclave at 150°C, heat and stir, and the pressure will reach the highest value with time , and then drop rapidly. When the pressure drops to about 0.5Mpa, the polymerization is completed. After standing for 1 hour, add lactic acid to adjust the pH value to 7-8, and obtain a clear, transparent, light yellow liquid polypropanol propyl ether;

[0032] Take 25g of methanol, 250g of propylene oxide, and 0.25g of sodium hydroxide and put them into an autoclave. Set the temperature of the kettle to 165°C. The method is the same as that of polypropanol propyl ether, and the product obtained is polymethanol propyl ether.

[0033] Take 100 g of polypropanol propyl ether and 2.5 g of boric acid into a three-neck flask, add the enhanced distillation agent zeolite molecular sieve, pass coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com