Transformer accessory replacing method

A replacement method and technology for transformers, applied in the manufacture of inductors/transformers/magnets, electrical components, switchgear, etc., can solve the problems of oil reduction and high failure rate, reduce oil storage equipment, improve work efficiency, and save work incidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

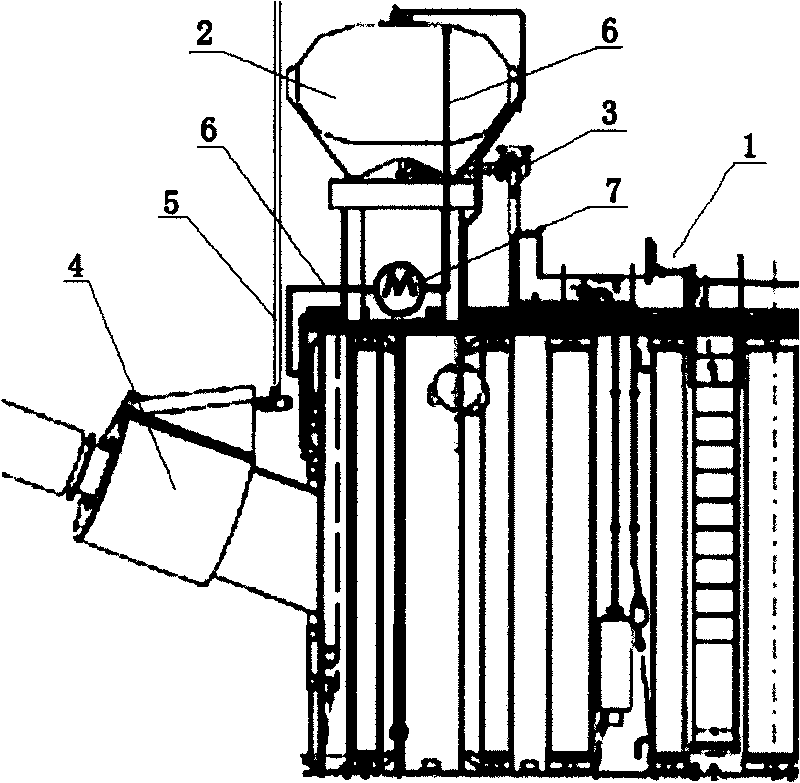

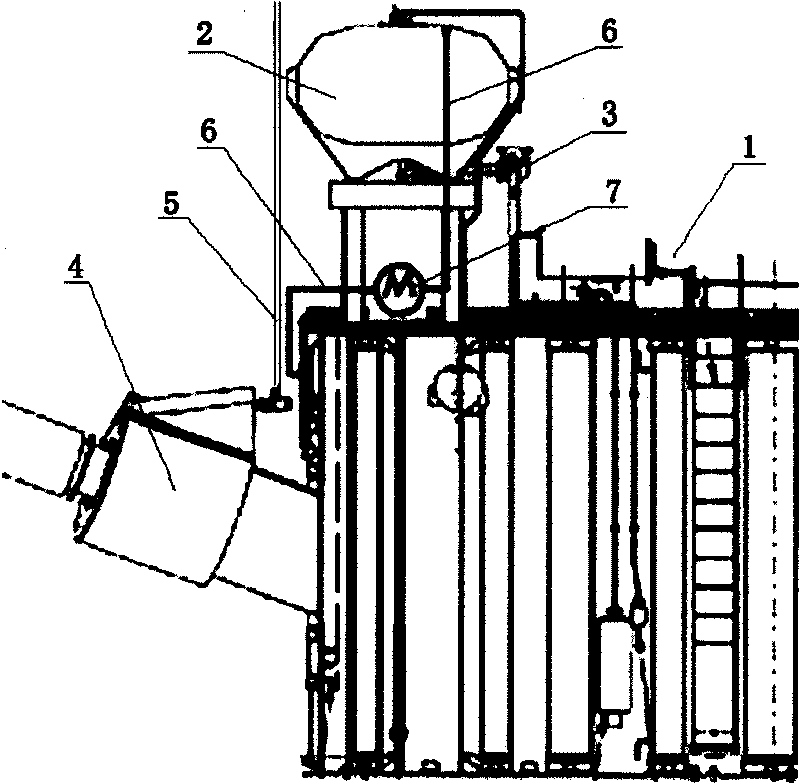

[0012] Such as figure 1 As shown, a transformer accessories replacement method, it includes the following steps:

[0013] (a) Connect a transparent plastic hose to the gas relay 4 of the transformer bushing as the oil level pipe 5, the length of which should be higher than the height of the oil conservator 2 of the main body, so as to observe the actual oil level;

[0014] (b) Connect the hose 6 on the transformer body 1 to the exhaust valve on the oil conservator 2, and connect the vacuum pump 7 in between;

[0015] (c) When pumping oil, it is necessary to close the valve 3 between the oil conservator 2 and the body 1;

[0016] (d) Observe the oil level of the oil level pipe 5 when pumping oil, and stop the vacuum pump 7 when it is lower than the replacement part;

[0017] (e) After the parts are replaced, open the valve 3 between the body 1 and the oil conservator 2, and put the oil down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com