Waveguide coaxial microstrip conversion circuit

A technology for converting circuits and microwave circuits, applied to circuits, waveguide devices, electrical components, etc., can solve the problems of microwave circuit sealing, failure to meet reliability requirements, and limit the maximum frequency of use, etc., to achieve simple structure and low cost , matching the effect of good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

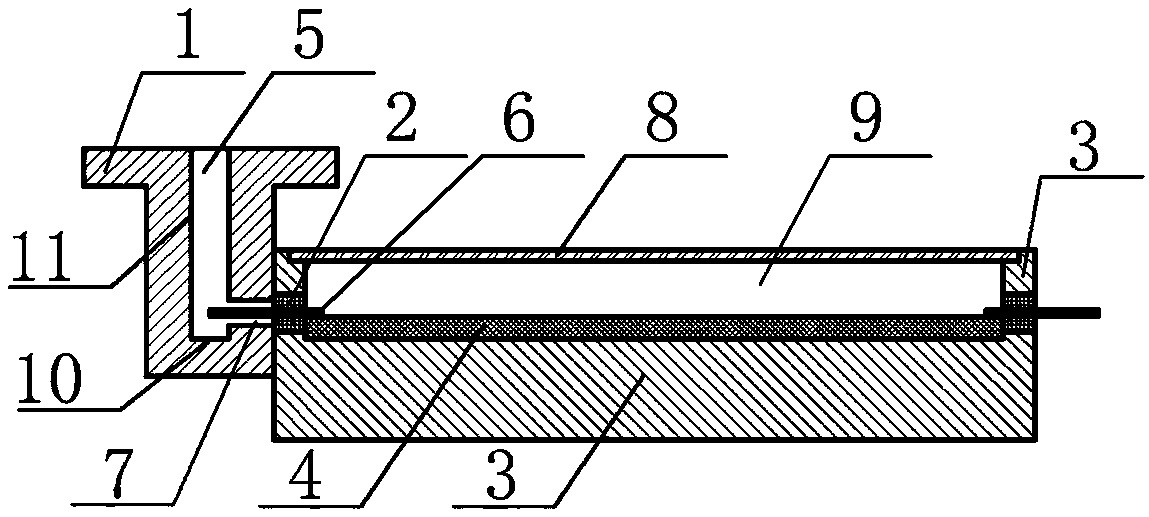

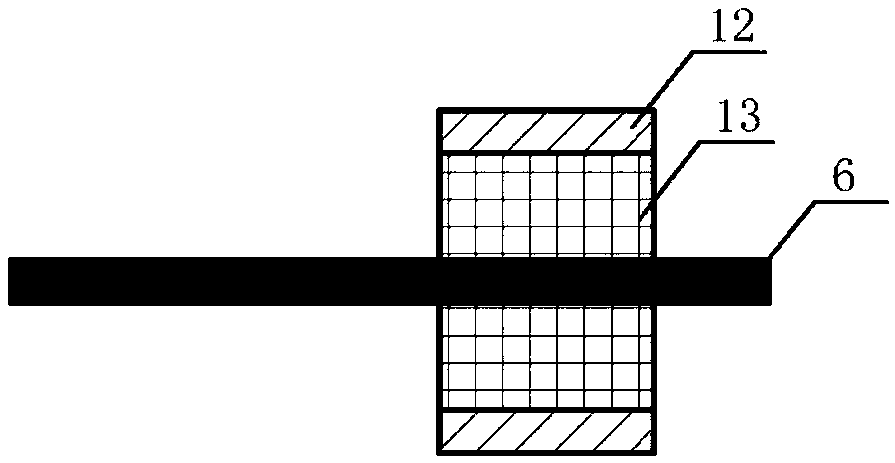

[0011] A waveguide coaxial microstrip conversion circuit, such as figure 1 and figure 2 As shown, it includes: rectangular waveguide connector 1, coaxial insulator 2, microwave circuit box body 3, microstrip circuit 4, waveguide cavity 5, inner conductor 6, through hole 7, cover plate 8, microwave cavity body 9, waveguide cavity bottom 10. Waveguide cavity side wall 11, outer conductor 12, insulating support structure 13, etc., wherein:

[0012] The present invention is generally composed of a rectangular waveguide connector 1 , a coaxial insulator 2 , a microwave circuit box 3 and a microstrip circuit 4 . The coaxial insulator 2 is composed of a coaxial cylindrical inner conductor 6 , an outer conductor 12 and an insulating support structure 13 , the inner conductor 6 passes through the middle of the insulating support structure 13 , and the outer conductor 12 is located outside the insulating support structure 13 . One end of the inner conductor 6 extends into the wavegui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com