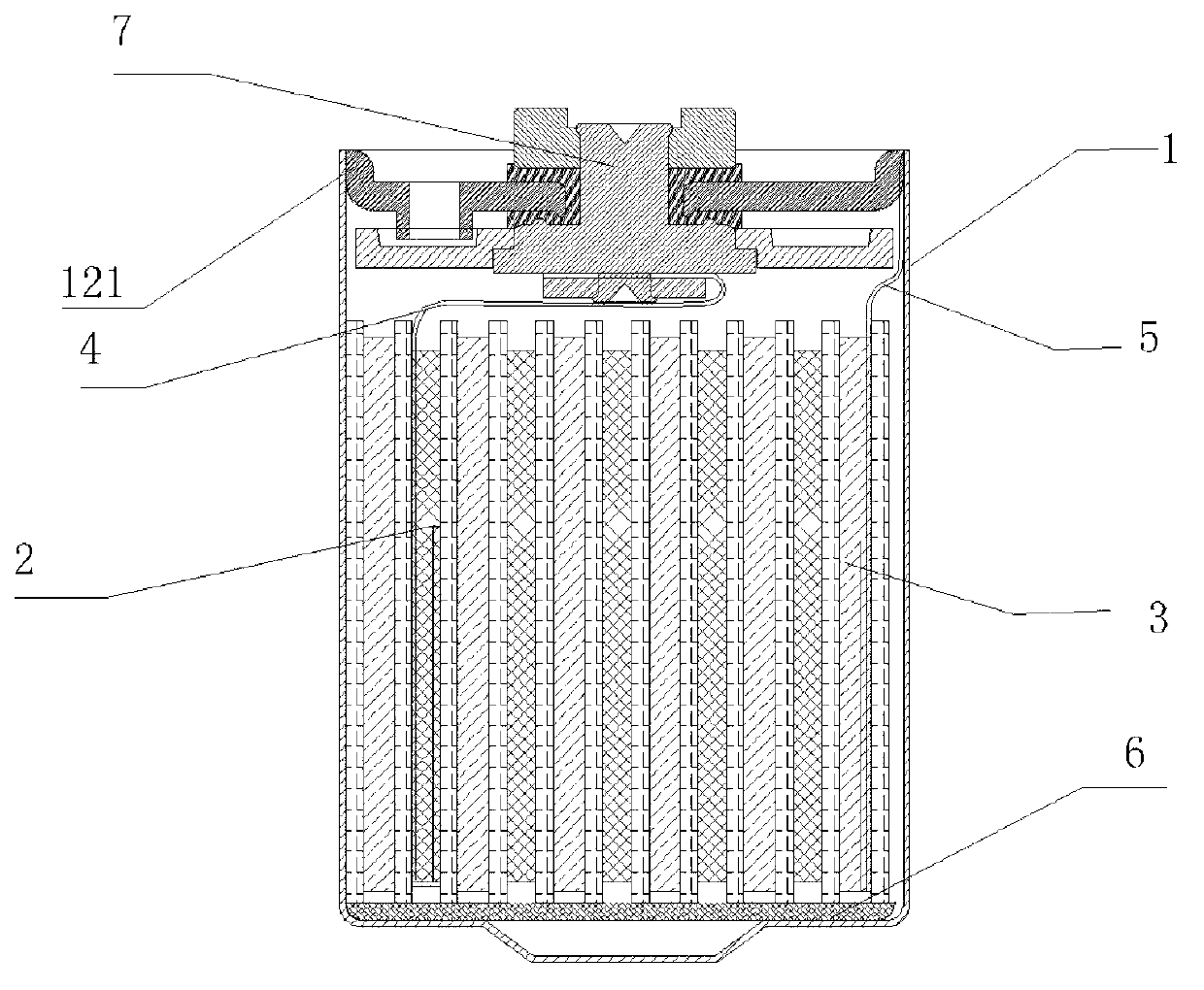

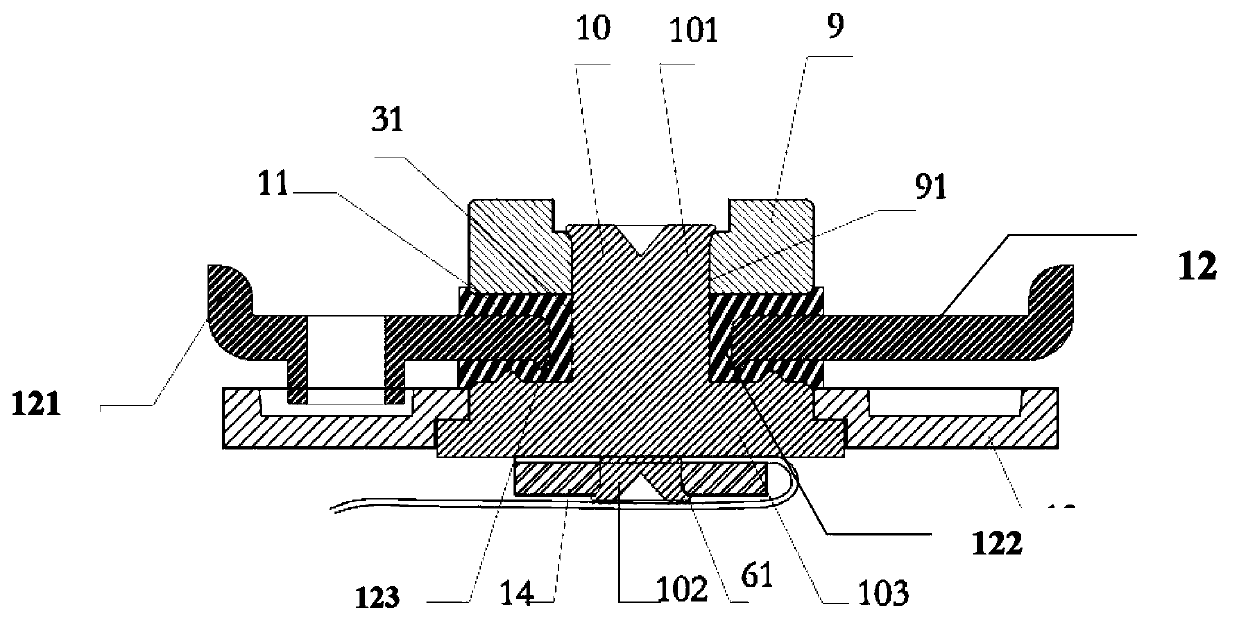

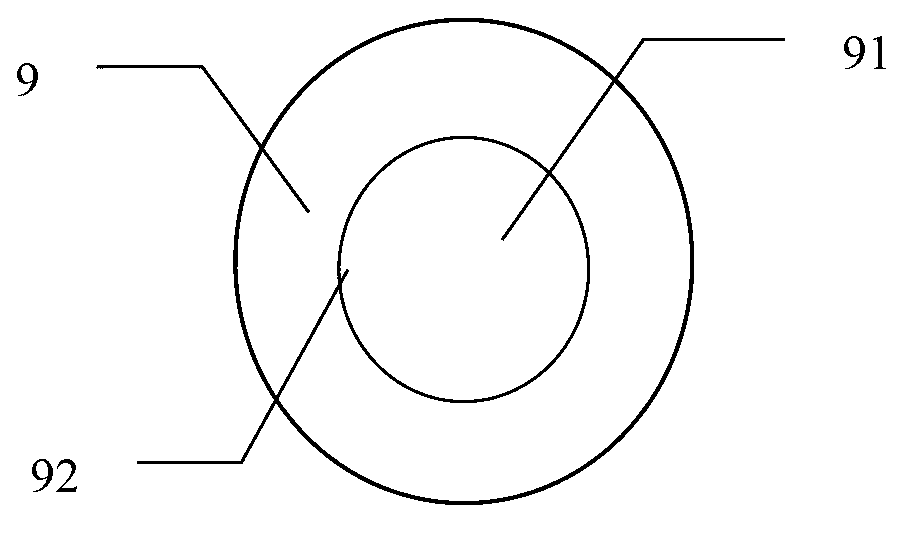

Cylinder battery capacitor

A technology for cylindrical batteries and capacitors, which is applied to battery pack parts, circuits, electrical components, etc. It can solve problems such as unsatisfactory sealing requirements, electrolyte leakage, and inconsistent thermal expansion coefficients, so as to avoid virtual soldering and over-soldering , Improve assembly efficiency and improve firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Test conditions: After charging the cylindrical battery capacitors separately, store them for 30 days at a temperature of 85°C and a relative humidity of 80%.

[0054] Test results: the following table.

[0055]

[0056] Conclusion: the cylindrical battery capacitor of the present invention is better than the conventional cylindrical battery capacitor in the environment of high temperature and high humidity.

Embodiment 2

[0058] Test conditions: After the cylindrical battery capacitors are charged separately, they are placed in an environment that simulates vehicle vibration.

[0059] Test results: the following table.

[0060]

[0061]

[0062] Conclusion: The cylindrical battery capacitor of the present invention has better sealing performance than the traditional cylindrical battery capacitor in the vehicle vibration environment.

Embodiment 3

[0064] Test conditions: After the cylindrical battery capacitors are charged separately, they are connected in parallel with ordinary lithium-ion batteries to form a battery pack, and the battery pack is stored at a constant temperature of -30°C, 23°C, 60°C, 70°C, and 80°C for 30 days. (Simulate the environment where smart water meters and smart gas meters exist).

[0065] Test results: the following table.

[0066]

[0067] Conclusion: The cylindrical battery capacitor of the present invention is better than the traditional cylindrical battery capacitor in the environment of low temperature and large temperature difference.

[0068] In combination with the embodiments, it can be concluded that the cylindrical battery capacitor provided by the present invention improves the sealing performance and can meet the requirements for sealing performance in the field of vehicle-mounted systems, smart gas meters and smart water meters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com