Emergency load rejection device for underwater robot

An underwater robot and horizontal axis technology, applied in underwater operation equipment, transportation and packaging, ships, etc., can solve problems such as poor versatility, complex structure, and poor reliability, and achieve simple and convenient installation, easy control, and increased Steady and high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

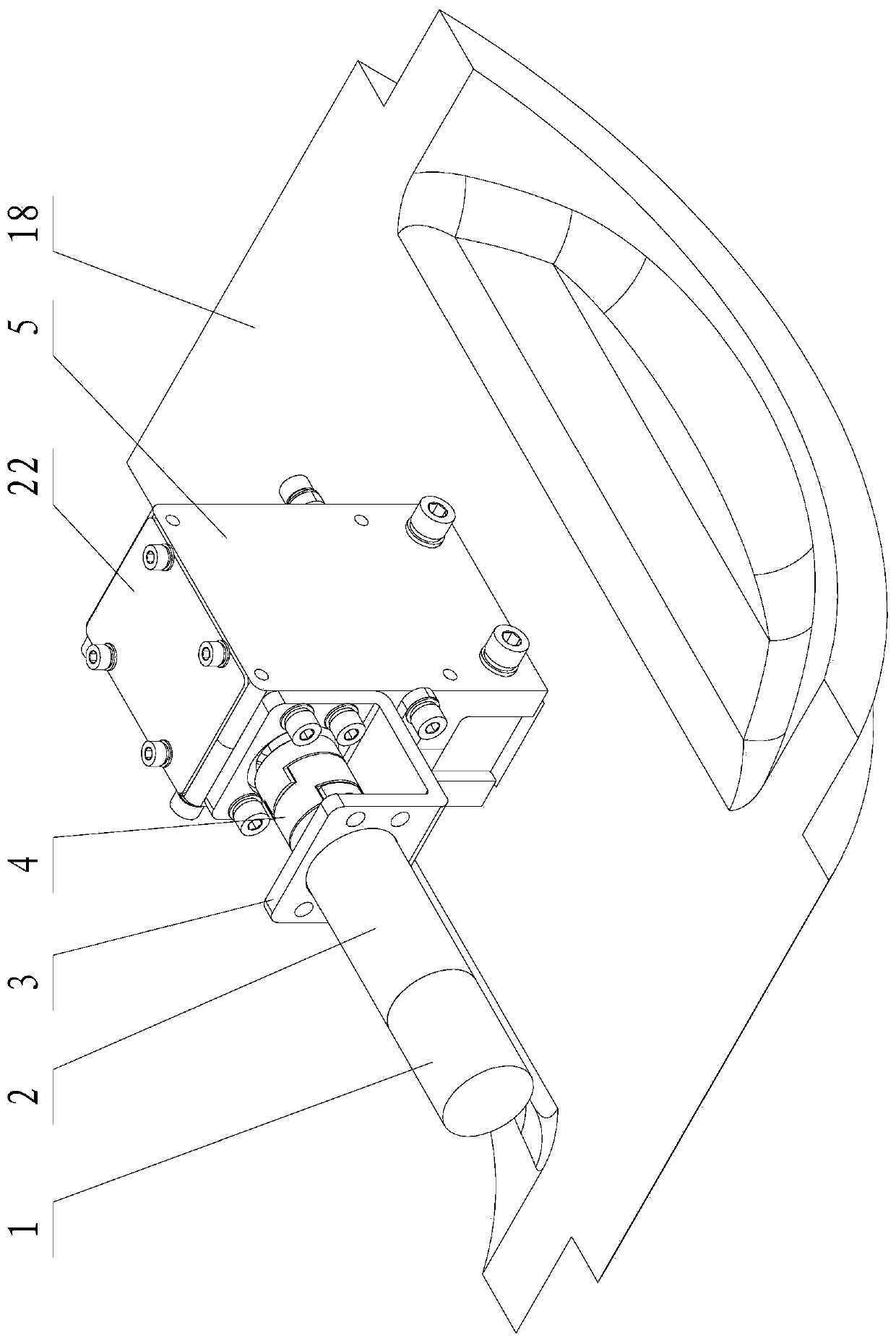

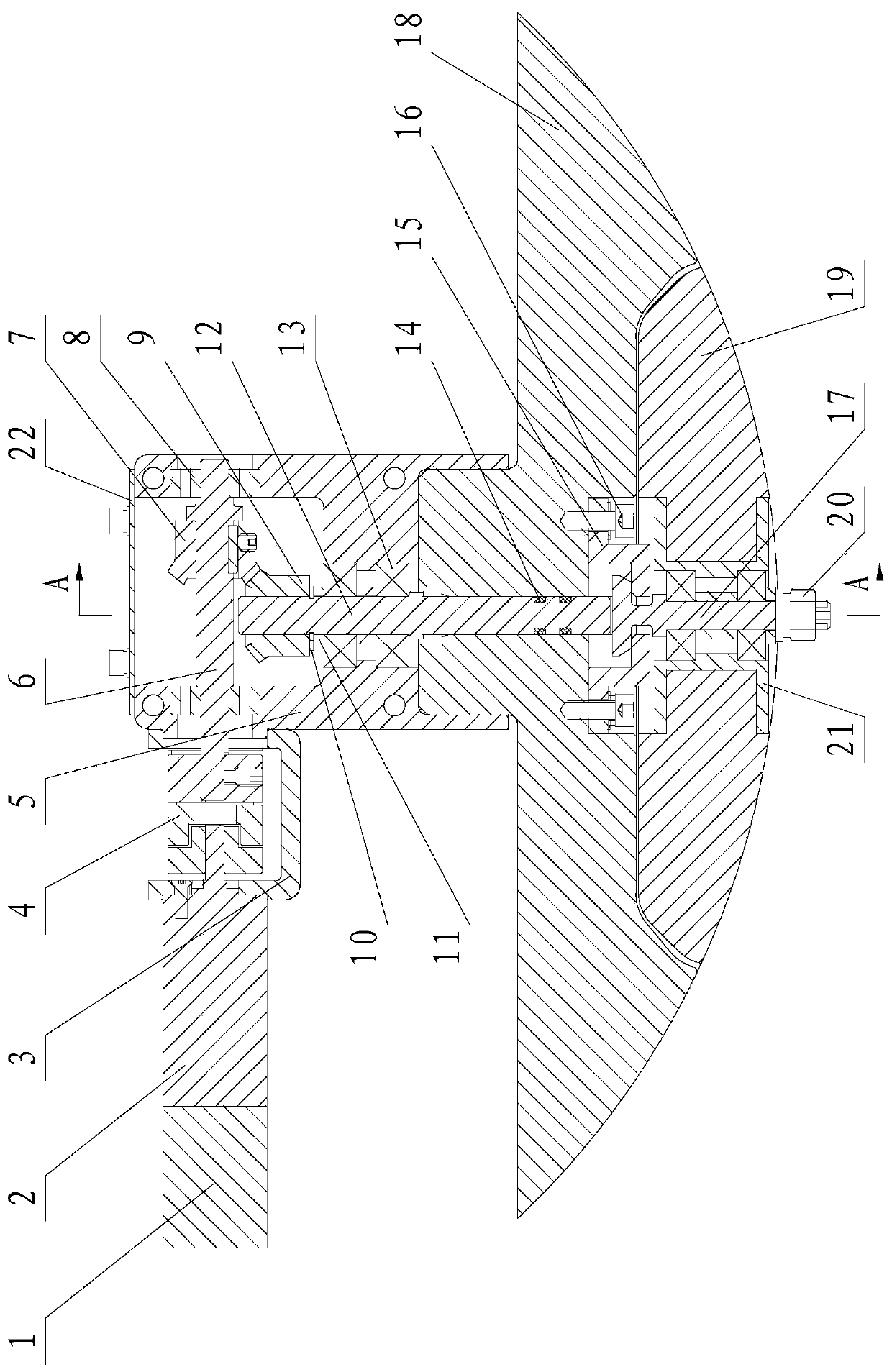

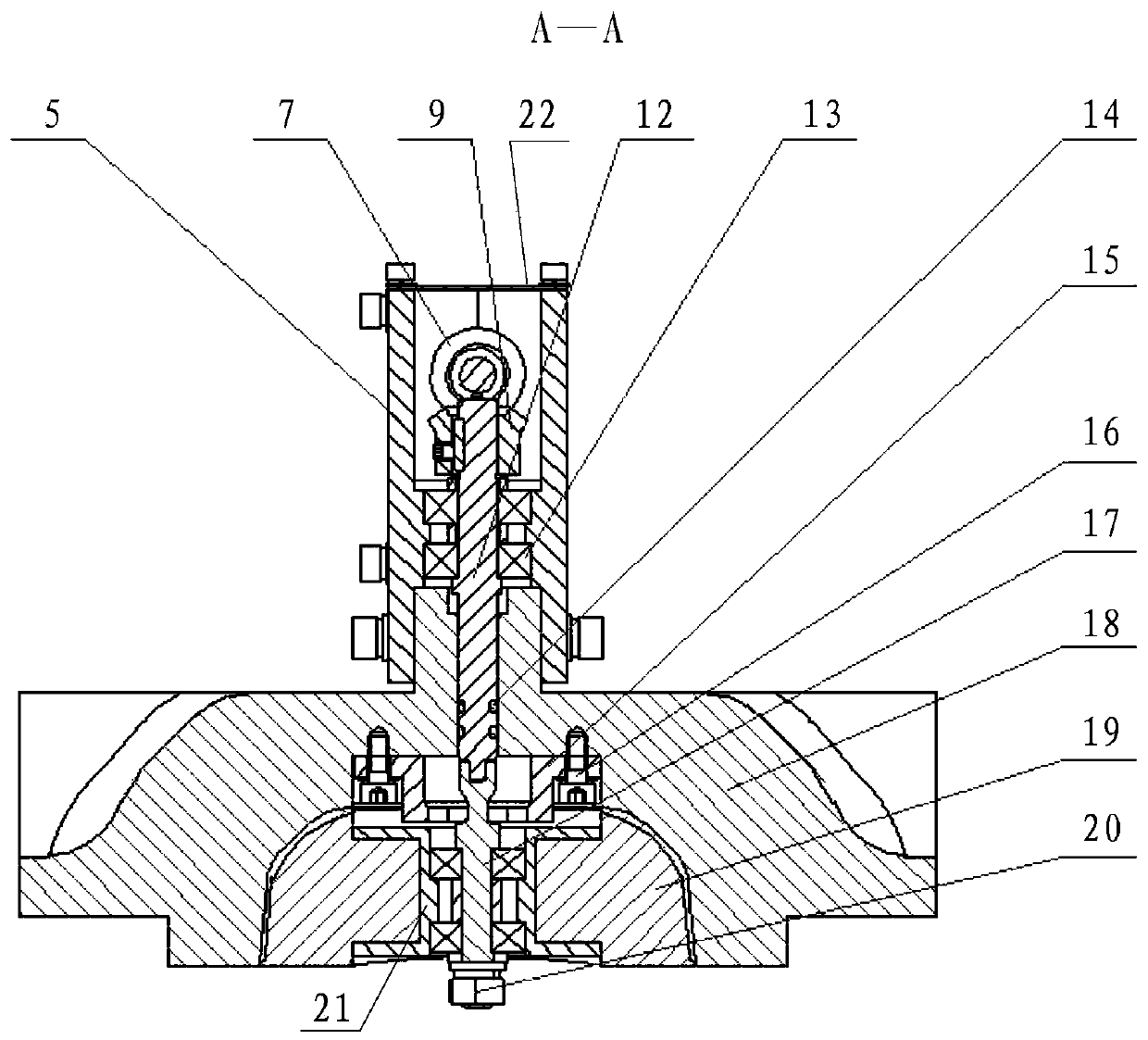

[0029] Such as Figure 1~3As shown, the present invention includes a power source, a motor fixing seat 3, a coupling 4, a load throwing fixing seat 5, a load throwing horizontal shaft 6, a matching helical gear A7, a horizontal angular contact bearing 8, a matching helical gear B9, and a snap spring 10. Sleeve 11, dumping vertical shaft 12, vertical angular contact bearing 13, dumping tray 15, dumping lead support 17, dumping base 18, dumping lead 19 and lead lock Nut 20, wherein the power source includes a DC motor 1 and a planetary gear reducer 2, the DC motor 1 and the planetary gear reducer 2 are plugged together and inserted on the motor holder 3, the motor holder 3 is fixed with the dump load The seats 5 are connected by screws; the DC motor 1, the planetary gear reducer 2 and the load-dumping horizontal shaft 6 are coaxially connected in series. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com