A safety dumping device for an underwater robot

An underwater robot and safety technology, applied in underwater operation equipment, transportation and packaging, ships, etc., can solve the problems of poor versatility, complex structure, high cost, etc., and achieve strong independence, simple mechanism, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

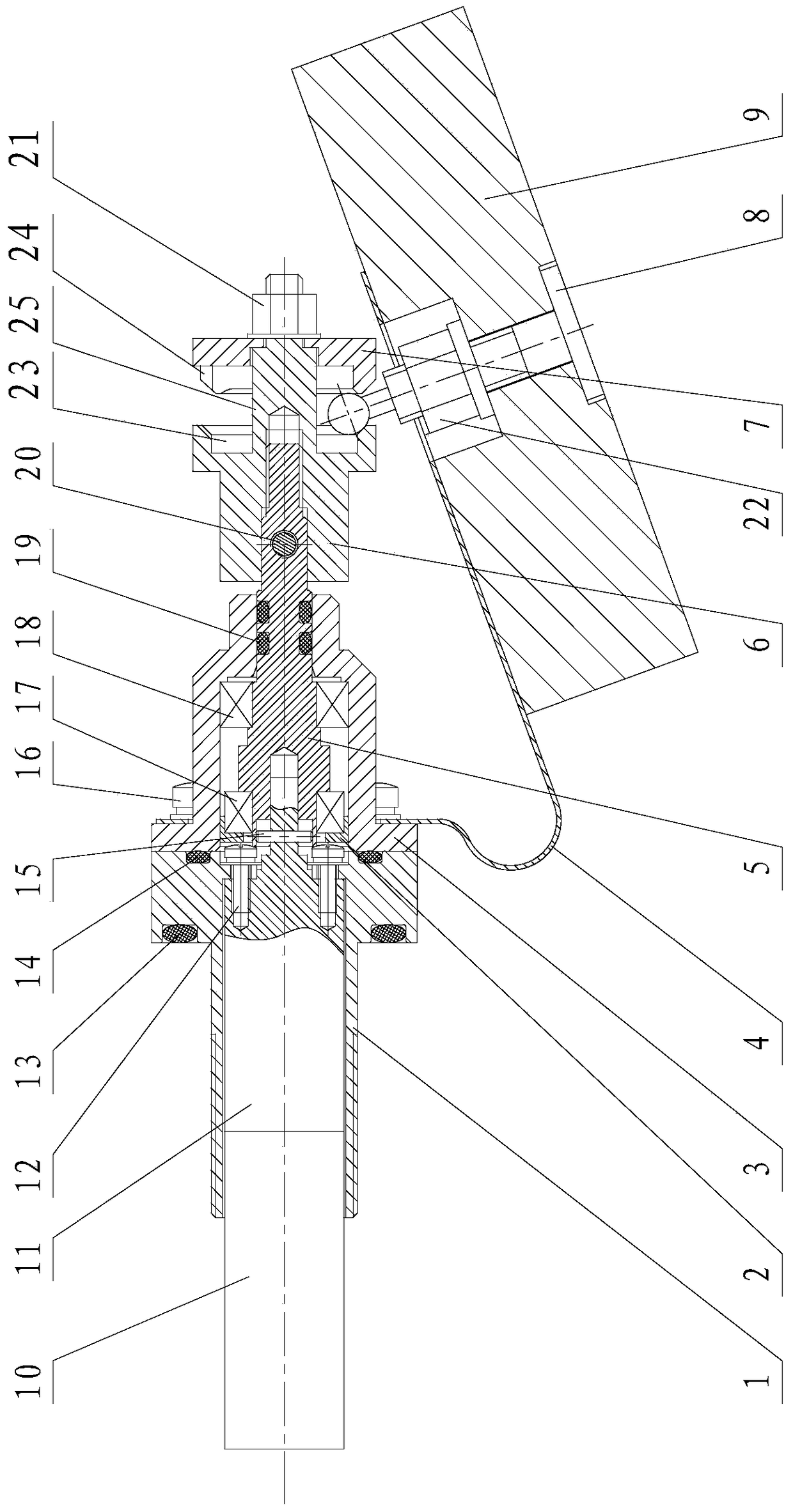

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, it includes motor fixing seat 1, bearing support seat 2, shaft sealing seat 3, spring leaf 4, load dumping shaft 5, runner 6, split wheel 7, ball head support 8, lead block 9, DC motor 10 and Planetary gear reducer 11, in which the motor fixing seat 1 is a cylindrical revolving body with a hollow "T" shape in the axial section, O-ring grooves are opened on both sides of the "T" shape, and O-ring grooves on one side An O-ring seal A13 is placed in the ring groove which is sealingly connected with the pressure-resistant shell of the underwater robot, and an O-ring seal B14 which is sealingly connected with the shaft seal seat 3 is placed in the O-ring groove on the other side; the DC motor 10 and the planetary gear reducer 11 are sequentially inserted in the motor holder 1 and connected in a coaxial direct connection.

[0020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com