Plate type heat exchanger on-site testing system with non-clean water as heat exchange medium

A technology of plate heat exchanger and heat exchange medium, which is applied in the direction of instruments, machine/structural component testing, measuring devices, etc., can solve the problems of cold source temperature being limited by the environment, complicated experimental working conditions, and large energy consumption, etc., to achieve The design and operation are highly instructive, the experimental data is true and reliable, and the system structure is simple and compact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific structure and work flow of the present invention will be further described in detail below in conjunction with the accompanying drawings.

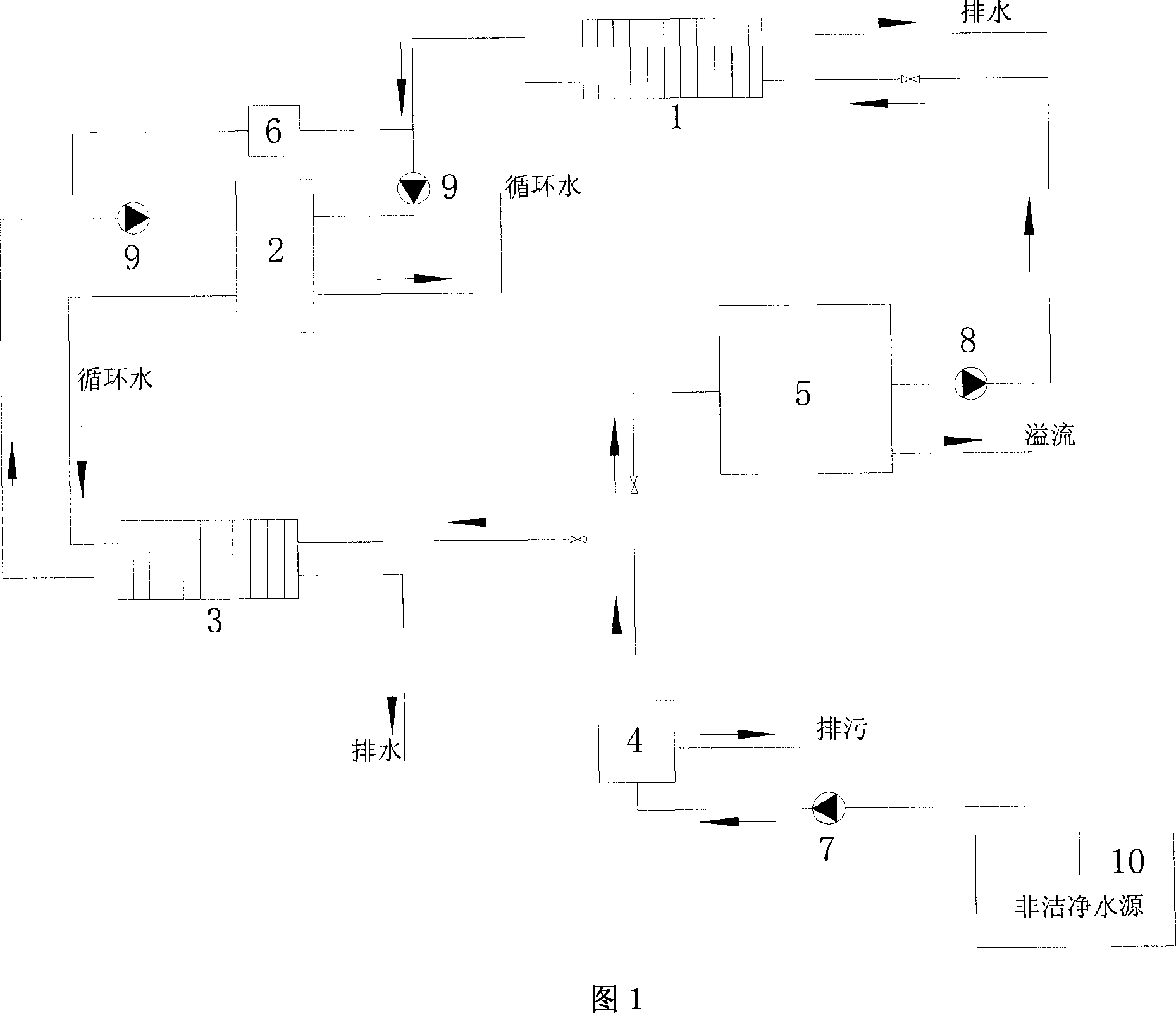

[0017] Figure 1 is a schematic diagram of the field experiment system of a plate heat exchanger with unclean water as the heat transfer medium. The experimental system includes the tested plate heat exchanger 1, heat pump 2, load plate heat exchanger 3, self-cleaning filter 4, water storage tank 5, water supply tank 6, water pump system, unclean water source 10 and the connection of the components pipeline; the unclean water source 10 is connected to the inlet of the self-cleaning filter 4 via the sewage lifting pump 7; the outlet pipe of the self-cleaning filter 4 is divided into two paths, one of which passes through the flow balance valve and the load plate heat exchanger 3 The non-clean water side inlet is connected to each other, and the other is connected to the inlet of the water storage tank 5 through a flow bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com