A Metering Pump Stroke Adjusting Mechanism

A stroke adjustment and metering pump technology, which is applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of difficult processing, low accuracy, and poor reproducibility, and achieve excellent processing technology, good linearity, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

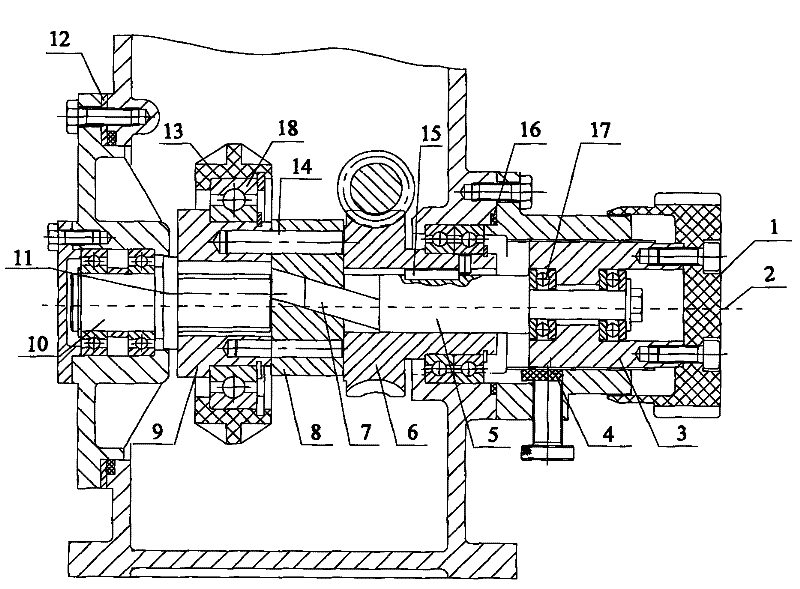

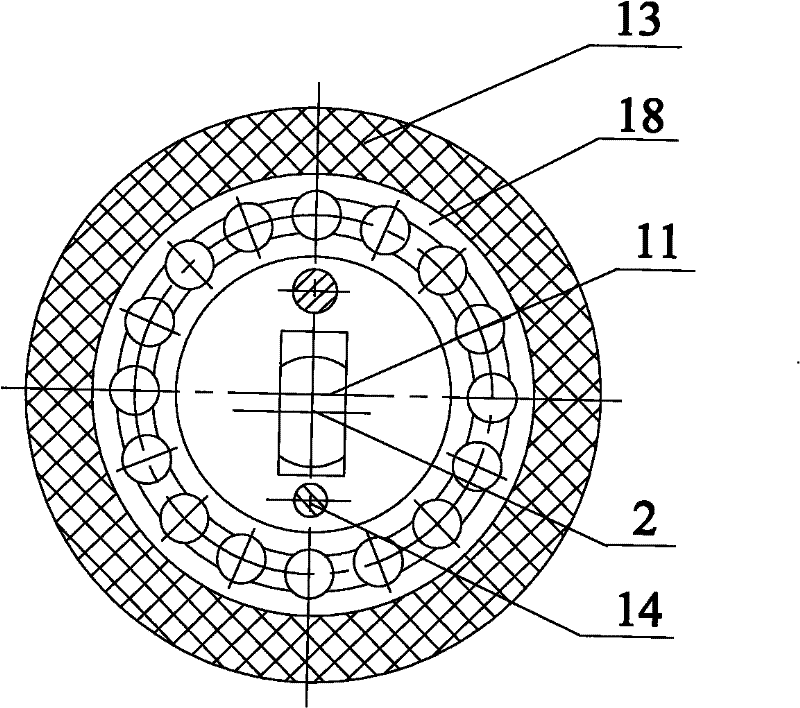

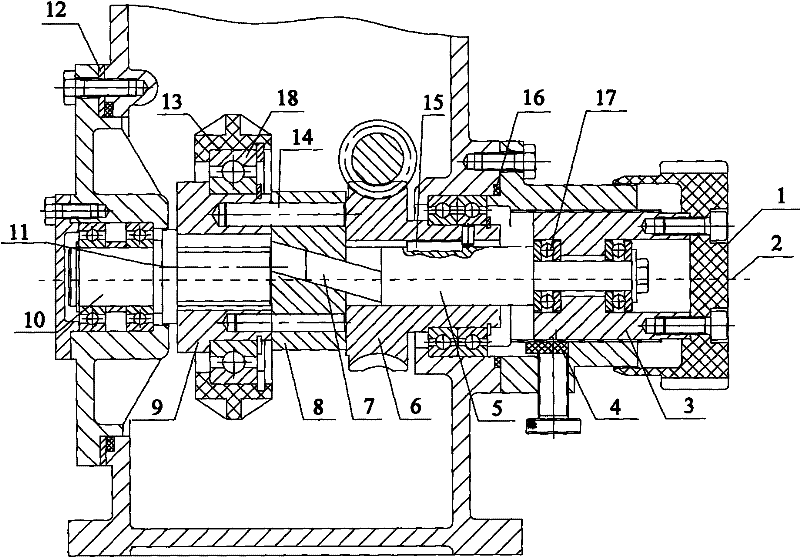

[0019] A metering pump stroke adjustment mechanism, its structure is as follows figure 1 As shown, the adjustment mechanism includes an adjustment hand wheel 1, a hollow screw sleeve 2, a push rod shaft 5, a worm wheel 6, an inclined block 7, a slider 8, a rotary sleeve 9, a guide shaft 10, a connecting rod 13 and a crank pin 14. The hand wheel 1 is connected to the front part of the hollow screw sleeve 3 by bolts, the front part of the push rod shaft 5 is set in the hollow screw sleeve 3, and the rear part is set in the worm wheel 6, and the hollow screw sleeve 3 and the push rod shaft 5 pass through the bearing 17 The hollow screw sleeve 3 is also provided with a locking block 4, the locking block 4 is used to fix the hollow screw sleeve 2, and then determine the relative position and connection between the inclined block 7 and the slider 8 connected to the tail of the push rod shaft 5 The stroke of rod 13. The rear portion of the push rod shaft 5 is also provided with a gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com