Sealing method for oil fog lubrication electric mainshaft bearing

A technology of oil mist lubrication and electric spindle, which is applied in the sealing of engines, parts of boring machines/drilling machines, drilling/drilling equipment, etc., which can solve problems such as burning and jamming, and achieve easy maintenance, good sealing effect and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

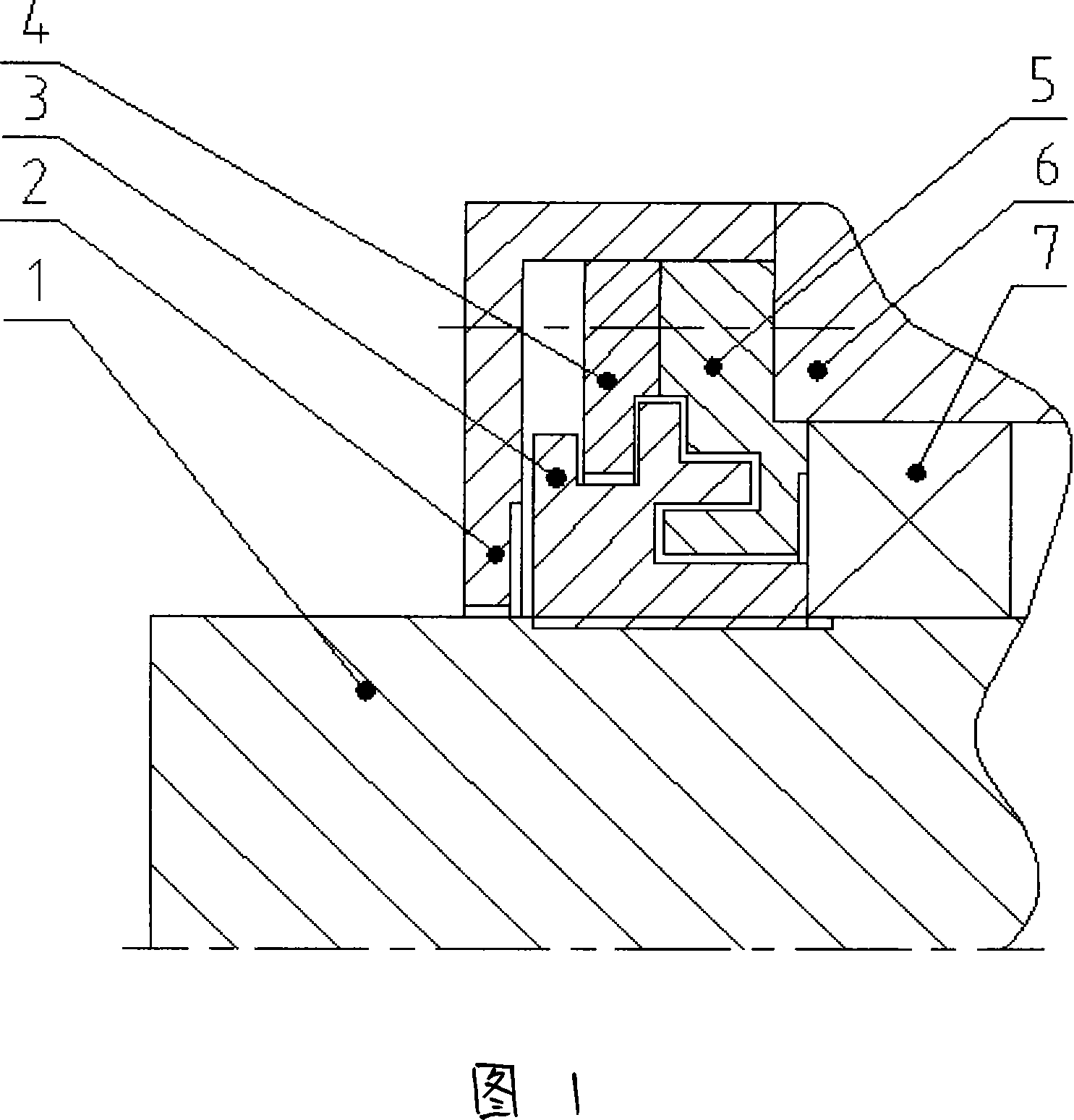

[0014] As shown in Figure 1: after the front bearing 7 and the rotating shaft 1 are fixed into the front bearing seat 6 at the front end of the electric spindle, the front small cover 5 is fixed on the front bearing seat 6 by screws at the outer end of the front bearing seat 6, and the electric Thread the front end of the spindle shaft 1, lock the front bearing 7 with the front nut 3, fix the two-piece baffle plate 4 on the front small cover 5 with screws, and then fix the dustproof with screws on the front end of the baffle plate 4 Cover 2.

[0015] A small gap seal is used between the front nut 3 and the baffle 4 . Waste oil mist is discharged from the gap here, so the size of the gap here should take into account the two points of sealing the bearing and allowing the waste oil to be discharged smoothly. After research and repeated tests, the diameter of the gap is controlled within the range of 0.4 ~ 0.6mm , the axial clearance is controlled within the range of 0.5-1 mm, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com