Heat exchanger and manufacturing method thereof

A processing method and technology of heat exchangers, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve problems such as bad heat exchangers, difficult to control the bending size, and strained fins, etc., to achieve Good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

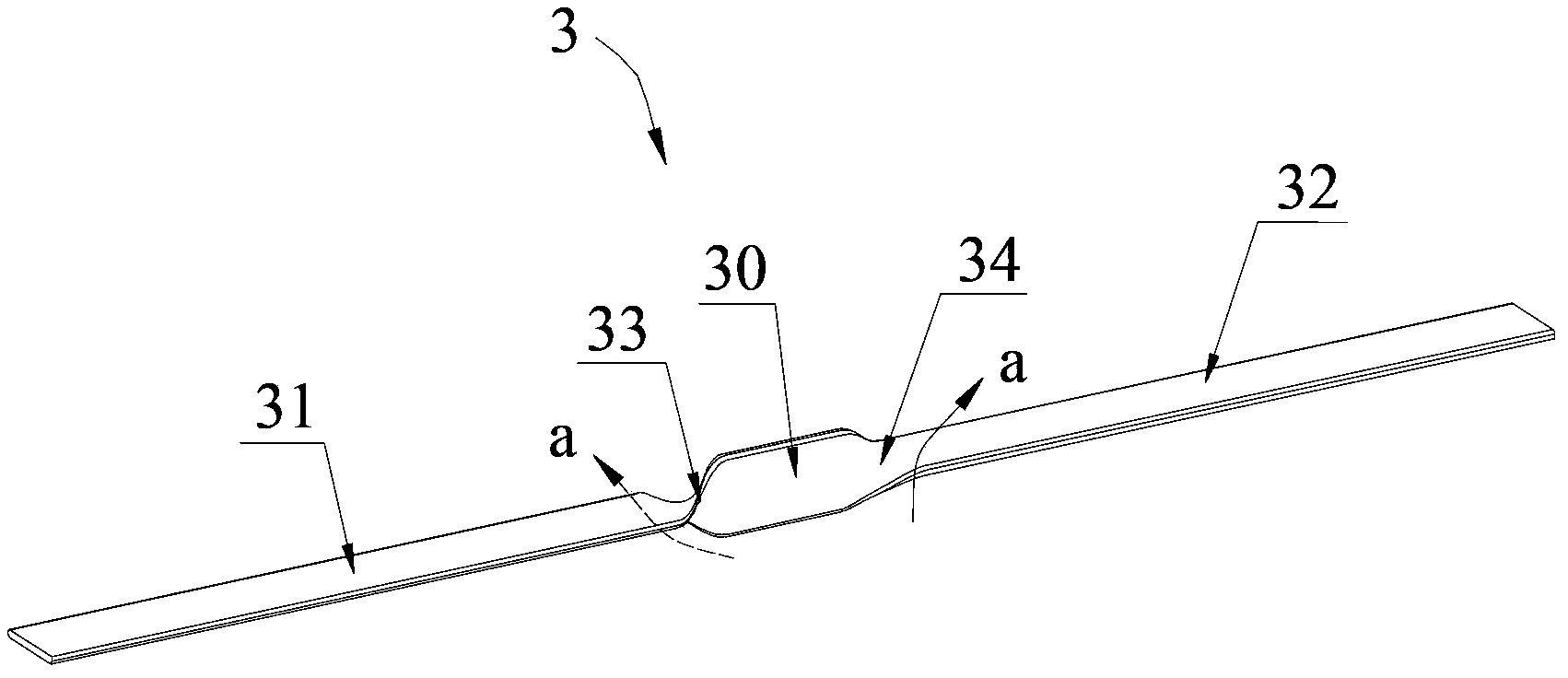

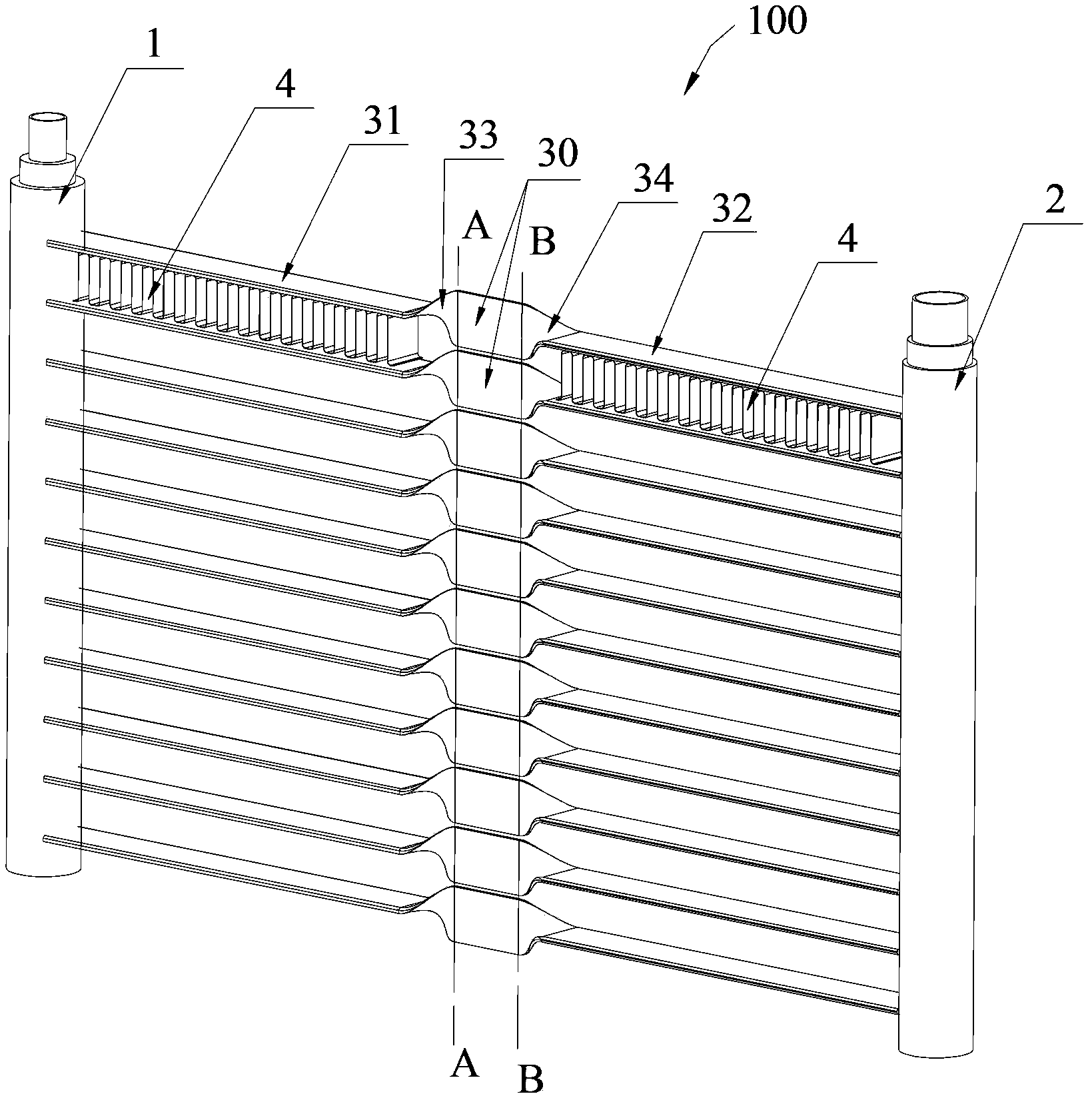

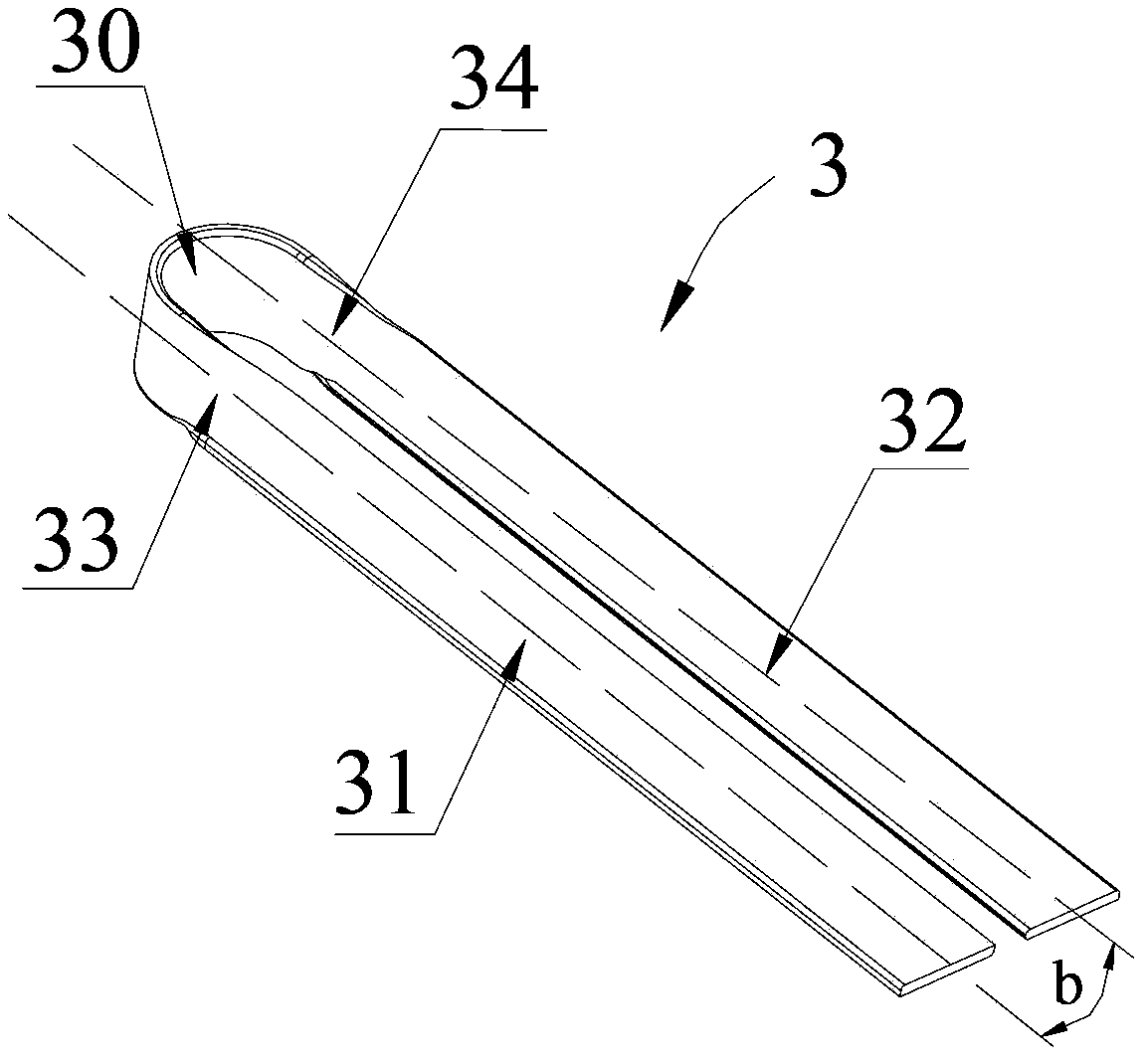

[0030] Please refer to figure 1 and figure 2 As shown, the present invention discloses a heat exchanger 100, which includes a first header 1, a second header 2, and a connection between the first header 1 and the second header 2. Several flat tubes 3 between them, and several fins 4 between adjacent flat tubes 3 . In the illustrated embodiment of the present invention, the heat exchanger 100 is a microchannel heat exchanger.

[0031] The first header 1 and the second header 2 are arranged parallel to each other and spaced apart on both sides of the heat exchanger 100 , one of which is an inlet pipe and the other is an outlet pipe. In the illustrated embodiment of the present invention, in order to improve the compressive strength of the entire heat exchanger 100, the first and second headers 1 and 2 are both cylindrical. The first and second headers 1 and 2 both extend vertically. Of course, in other embodiments, the positional relationship between the first and second he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com