Preparation method of high-permeability and high-elastic polyurethane elastomer

A technology of polyurethane elastomer and polyurethane prepolymer, applied in the field of polyurethane application, can solve the problems of narrow hardness range, poor resilience, and reduced transparency of high-elastic elastomers, and achieves excellent processing performance, low equipment requirements, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

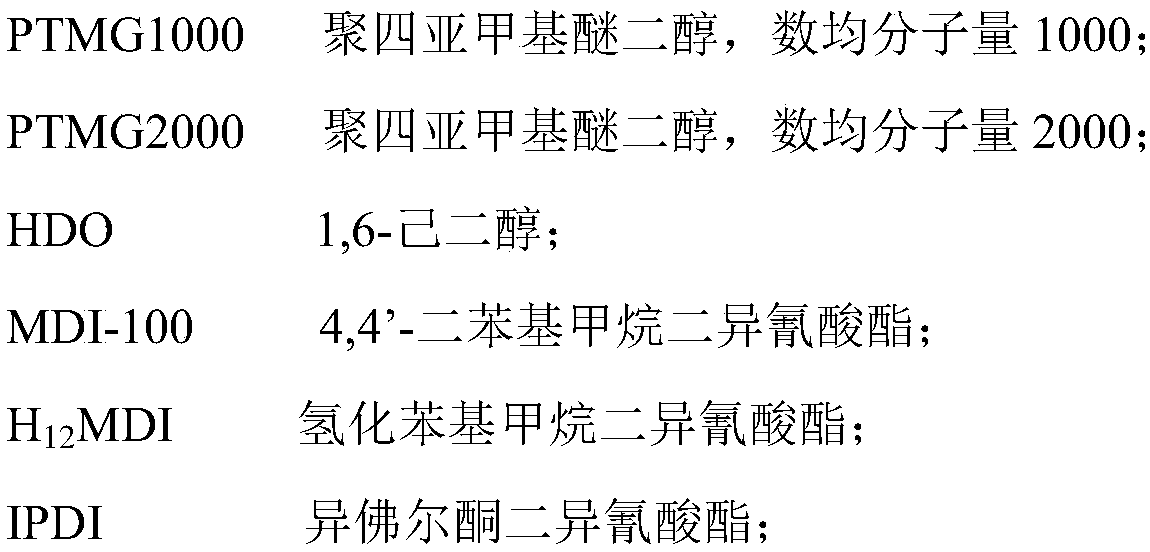

[0038] The components of the two-component high-permeability and high-elasticity polyurethane elastomer are as follows:

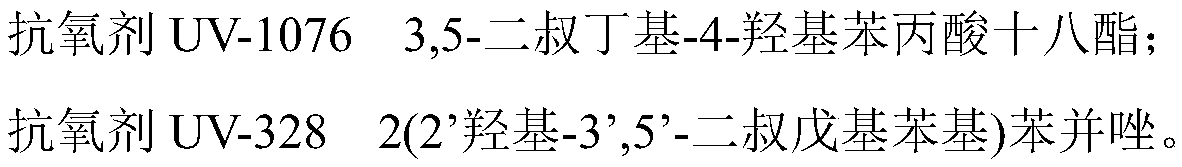

[0039] Component A: 93% and 7% of PTMG2000 and HDO with moisture content ≦0.03%, respectively, 0.4% of bismuth catalyst, 0.2% of antioxidant UV-1076 and 0.3% of UV-328, mix well to obtain component A.

[0040] Component B: PTMG2000 66.4% and MDI-100 33.6% with moisture content≦0.03% were reacted at 85°C for 2.5 hours, and vacuum (-0.095MPa) was used to remove air bubbles to obtain a prepolymer with an isocyanate content of 8.5%.

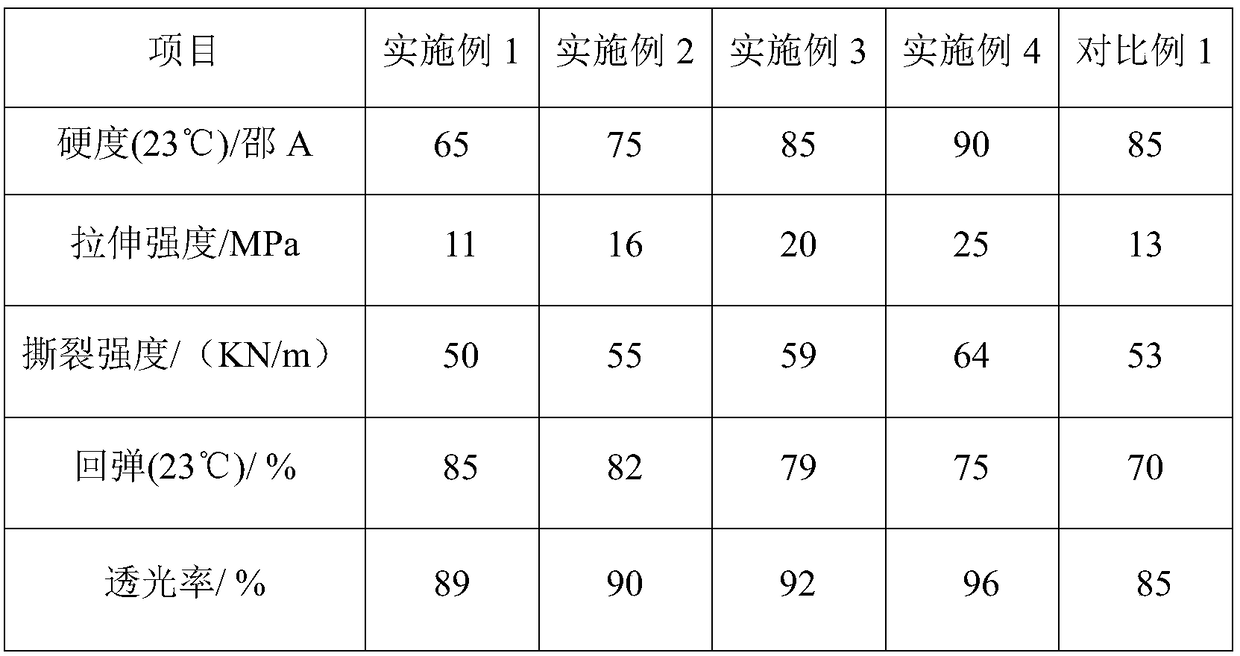

[0041] The mixing temperature of A and B two-components is controlled at 65°C. After mixing evenly according to the mass ratio of A:B=100:100, pour it into a mold at 75°C, and open the mold for 40 minutes. The hardness can be obtained as Shore 65A. Rebound is 85% high-permeability and high-elasticity polyurethane elastomer.

Embodiment 2

[0043] The components of the two-component high-permeability and high-elasticity polyurethane elastomer are as follows:

[0044] Component A: PTMG1000 with moisture content ≦0.03%, PTMG2000 and HDO 25%, 65% and 10%, bismuth catalyst 0.5%, antioxidant UV-1076 0.2% and UV-328 0.3%, mix well to get A components.

[0045]Component B: PTMG2000 63% and MDI-100 37% with moisture content≦0.03% were reacted at 85°C for 2.5 hours, and vacuum (-0.095MPa) was used to remove air bubbles to obtain a prepolymer with an isocyanate content of 9.8%.

[0046] The mixing temperature of A and B two-components is controlled at 65°C. After mixing evenly according to the mass ratio of A:B=80:100, pour it into a mold at 75°C, and open the mold for 40 minutes. The hardness can be obtained as Shore 75A. Rebound is 82% high-permeability and high-elasticity polyurethane elastomer.

Embodiment 3

[0048] The components of the two-component high-permeability and high-elasticity polyurethane elastomer are as follows:

[0049] Component A: PTMG1000 with moisture content ≦0.03%, PTMG2000 and HDO 41.7%, 38.3% and 20% respectively, bismuth catalyst 0.6%, antioxidant UV-1076 0.2% and UV-328 0.3%, mix well to get A components.

[0050] B component: PTMG2000 57% and MDI-100 38.7% with moisture content≦0.03%, H 12 MDI 4.3% was reacted at 85° C. for 2 hours, and vacuum (-0.095 MPa) was used to remove air bubbles to obtain a prepolymer with an isocyanate content of 12%.

[0051] The mixing temperature of A and B two-components is controlled at 65°C. After mixing evenly according to the mass ratio of A:B=60:100, pour it into a mold at 75°C, and open the mold for 40 minutes. The hardness can be obtained as Shore 85A. Rebound is 79% high-permeability and high-elasticity polyurethane elastomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com