Method for manufacturing metal matrix ceramic composite part

A ceramic composite material and manufacturing method technology, applied in the field of material manufacturing and machining, can solve the problems of rising cost, inability to high-precision parts, ultra-high-precision machining, immature technology, etc., to reduce difficulty and cost, and reduce post-processing. Process and processing volume, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the drawings and embodiments.

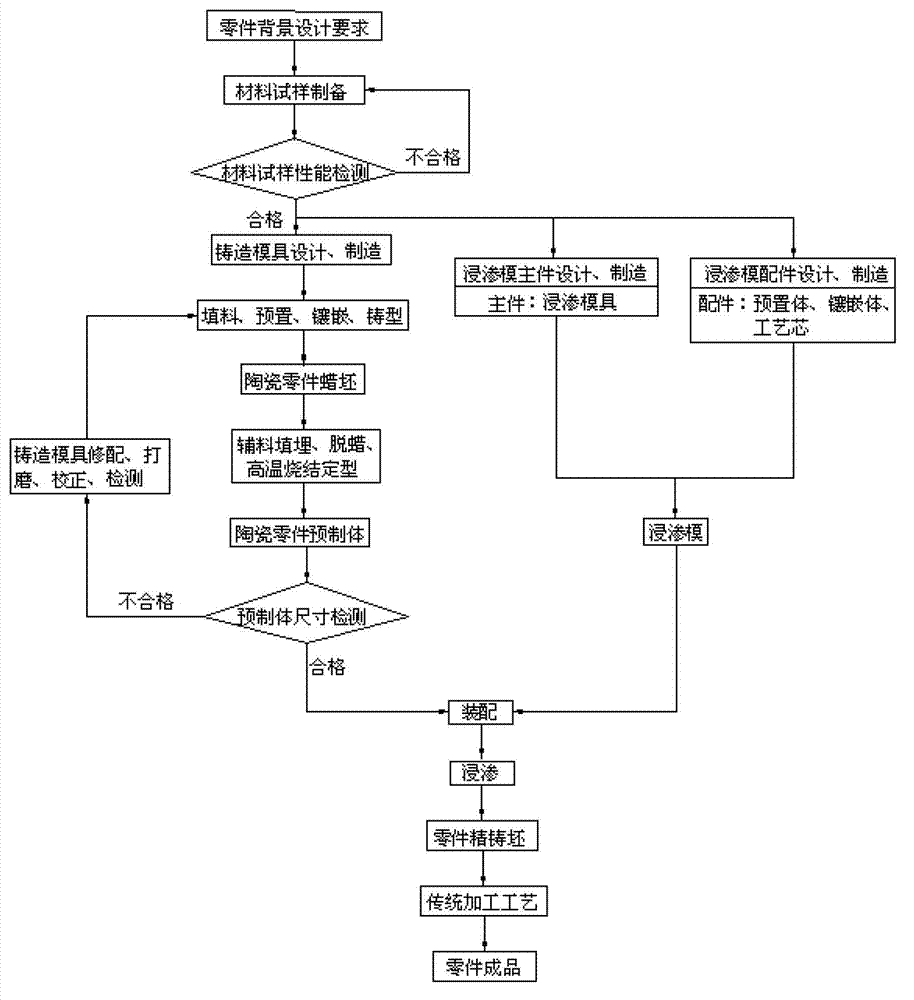

[0034] Such as figure 1 Shown is a flow chart of the manufacturing method of metal-based ceramics or metal-based ceramic composite parts of the present invention. The method includes the following steps:

[0035] 1) According to the background design requirements of specific parts of metal-based ceramic composite materials, use the traditional infiltration preparation method of metal-based ceramic composite materials to prepare material samples;

[0036] 2) Perform performance testing on the material samples. If the material performance requirements of the metal-based ceramic composite parts are not met, the sample preparation will be performed again; if the material performance requirements of the metal-based ceramic composite parts are met, then the casting mold will be manufactured;

[0037] 3) Design and manufacture casting molds according to the shape of metal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com