Medical used titanium alloy for surgery implantation material

A surgical implant and titanium alloy technology, applied in medical science, prosthesis, etc., can solve the problems of vanadium containing toxic components, low strength of pure titanium, short development history, etc., and achieve good comprehensive mechanical properties, good biomechanics Compatibility, effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

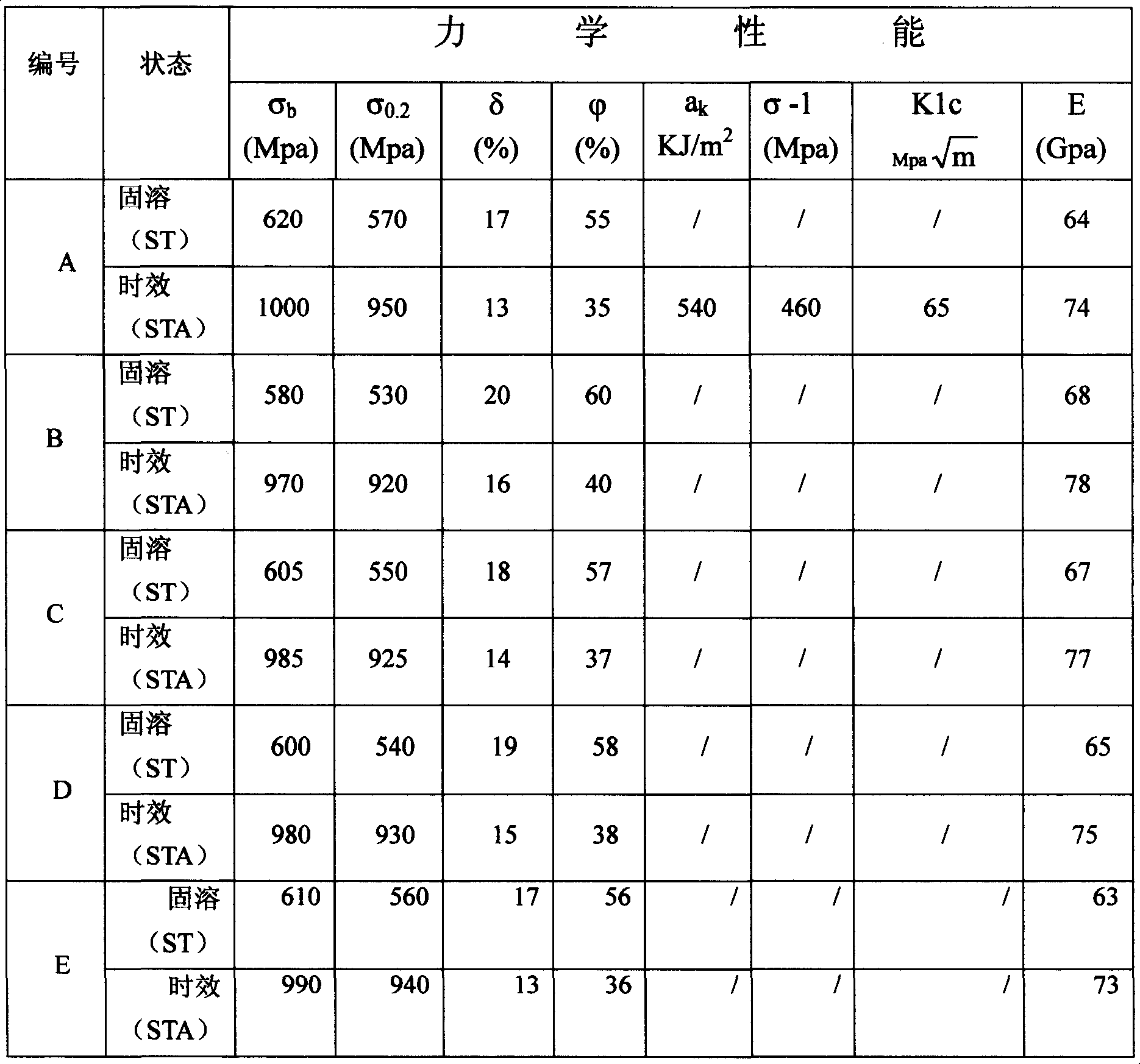

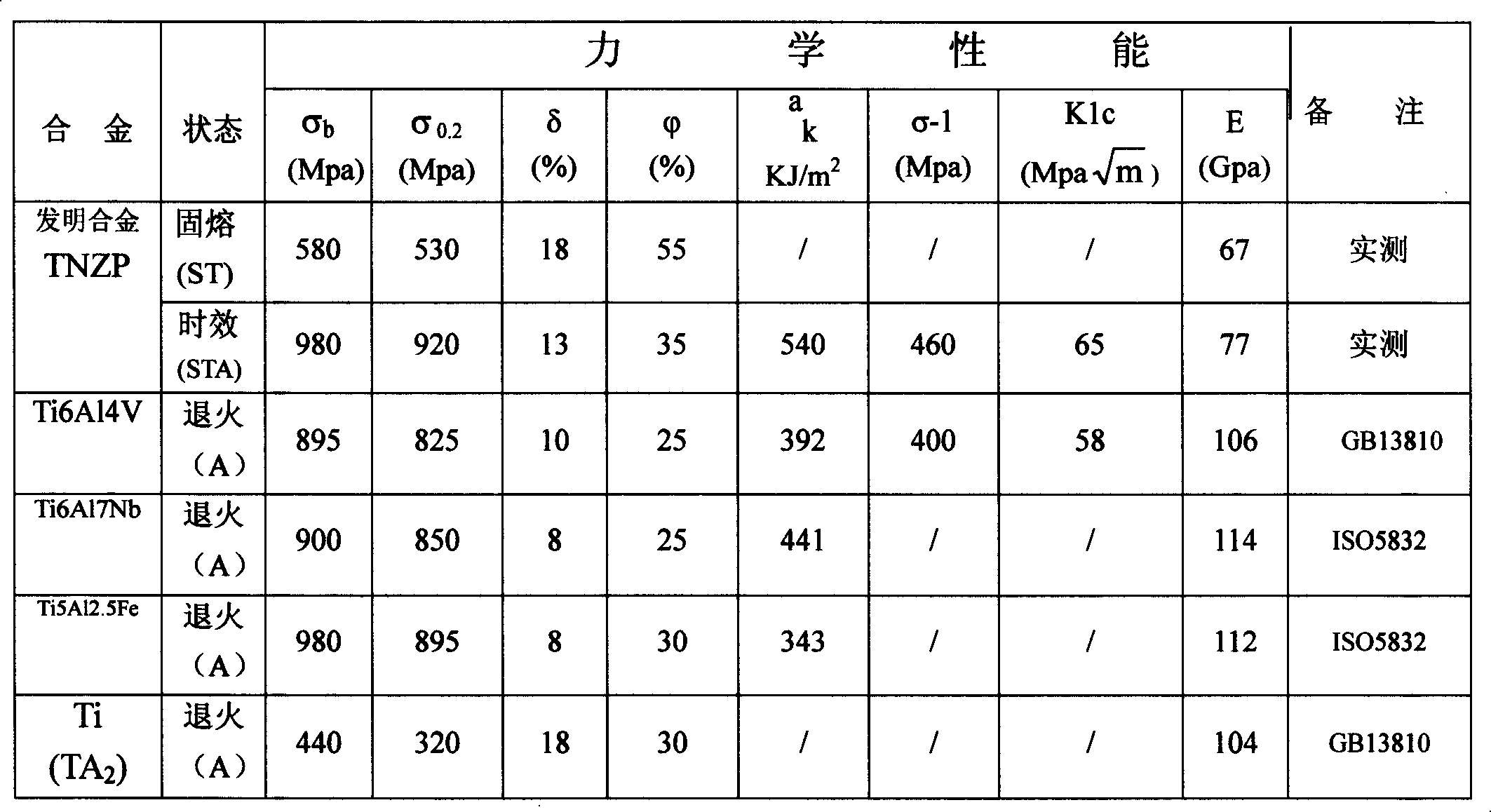

Embodiment 1

[0008] First-grade small particle sponge titanium, atomic energy grade sponge zirconium, industrial palladium powder and niobium-titanium master alloy are used for batching. The design masses of each component are: titanium (Ti) 64.85 kg, niobium (Nb) 27 kg, zirconium (Zr) 8 kilograms, palladium (Pd) 0.15 kilograms. The electrode is made, then smelted in a vacuum consumable electric arc furnace, and pressed at 800-1050°C, processed into a 15-30mm bar, solution treated at 700-900°C, and aged at 450-650°C. Above-mentioned processing technology can be carried out by the method of prior art.

Embodiment 2

[0010] First-grade small particle sponge titanium, atomic energy grade sponge zirconium, industrial palladium powder and niobium-titanium master alloy are used for batching. The design masses of each component are: titanium (Ti) 55.8 kg, niobium (Nb) 32 kg, zirconium (Zr) 12 kilograms, palladium (Pd) 0.2 kilograms. The electrode is made, then smelted in a vacuum consumable electric arc furnace, and pressed at 800-1050°C, processed into a 15-30mm bar, solution treated at 700-900°C, and aged at 450-650°C. Above-mentioned processing technology can be carried out by the method of prior art.

Embodiment 3

[0012] First grade small particle sponge titanium, atomic energy grade sponge zirconium, industrial palladium powder and niobium-titanium master alloy are used for batching. The design masses of each component are: titanium (Ti) 72 kg, niobium (Nb) 22 kg, zirconium (Zr) 5.83 kg, palladium (Pd) 0.17 kg. The electrode is made, then smelted in a vacuum consumable electric arc furnace, and pressed at 800-1050°C, processed into a 15-30mm bar, solution treated at 700-900°C, and aged at 450-650°C. Above-mentioned processing technology can be carried out by the method of prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com