Inner liner sizing material for semi-steel-wire radial ply tire

A technology for radial tires and inner liners, which is applied in the production of rubber materials for tire inner liners, can solve problems such as unguaranteed production demand, price and supply fluctuations of halogenated butyl rubber, and achieve good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

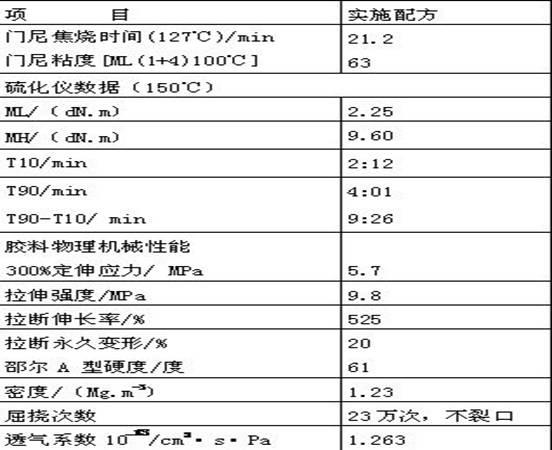

Embodiment 1

[0012] raw material invention compound Chlorobutyl rubber 55.0 SBR1712 20.5 Imported 20# natural rubber 25.0 Modified chlorosulfonated rubber 5.0 light calcium carbonate 25.0 203 resin 4.0 RT-40FE 6.0 stearic acid 1.0 Antiaging agent RD 2.0 Carbon black N660 58.0 Aromatic oil 2.5 Active Zinc Oxide 4.0 Accelerator NS 1.5 accelerator TBzTD 0.2 Insoluble sulfur IS-6005 0.5 Vulcanizing agent WP5 0.7

[0013] In this example, imported natural rubber (code SMR20#), chlorinated butyl rubber (code CIIR1066), styrene-butadiene rubber (code SBR1712), modified chlorosulfonated rubber (code CSM), leveling agent resin (code RT -40FE) is first added to the internal mixer for mixing. Since the rubber material is composed of multiple rubber types, in order to fully ensure the quality of the mixed rubber and the airtight performance of the vulcanized rubber, the mixing time of a master ...

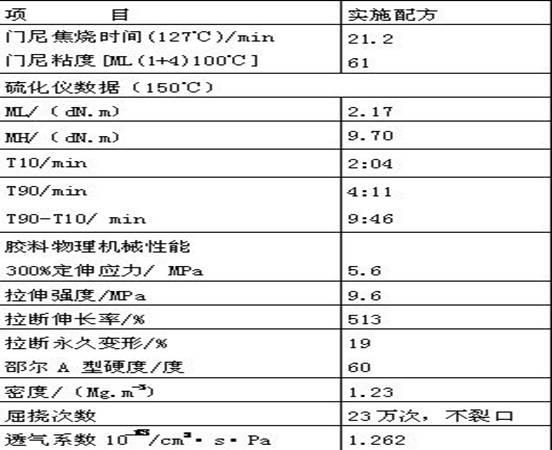

Embodiment 2

[0018] raw material invention compound Chlorobutyl rubber 60.0 SBR1712 20.5 Imported 20# natural rubber 20.0 Modified chlorosulfonated rubber 5.0 light calcium carbonate 25.0 203 resin 4.0 RT-40FE 6.0 stearic acid 1.0 Antiaging agent RD 2.0 Carbon black N660 58.0 Aromatic oil 2.5 Active Zinc Oxide 4.0 Accelerator NS 1.5 accelerator TBzTD 0.2 Insoluble sulfur IS-6005 0.5 Vulcanizing agent WP5 0.7

[0019] In this example, imported natural rubber (code SMR20#), chlorinated butyl rubber (code CIIR1066), styrene-butadiene rubber (code SBR1712), modified chlorosulfonated rubber (code CSM), leveling agent resin (code RT -40FE) is first added to the internal mixer for mixing. Since the rubber material is composed of multiple rubber types, in order to fully ensure the quality of the mixed rubber and the airtight performance of the vulcanized rubber, the mixing time of a master ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com