Rubber composition for tires

A technology of rubber composition and tire, applied in the field of rubber composition of tire tread, can solve problems such as low dispersibility, and achieve the effects of low heat build-up and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

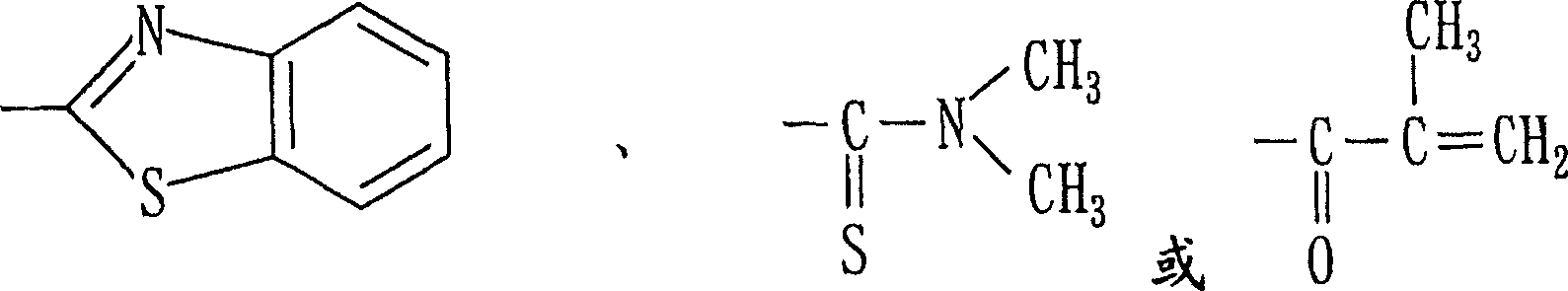

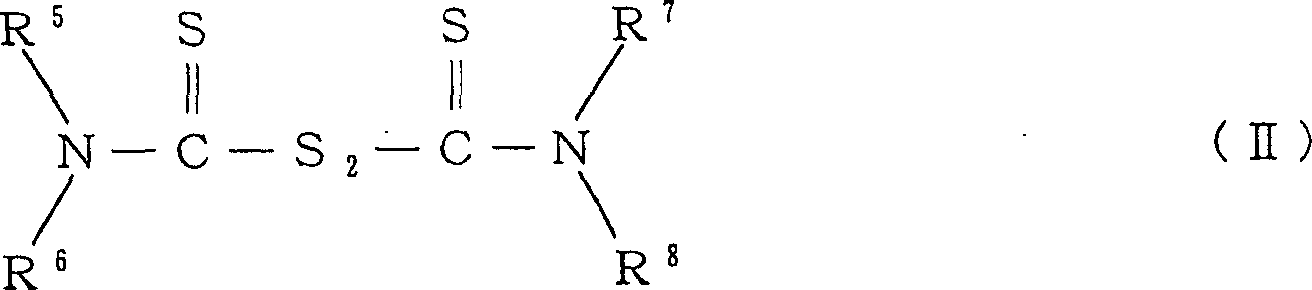

Method used

Image

Examples

Embodiment 1~3 and comparative Embodiment 1~4

[0054] Preparation of test samples

[0055] The components of each rubber formulation shown in Table I below, except sulfur and vulcanization accelerator, were mixed in a 1.8 liter internal mixer for 3-5 minutes. When 150°C was reached, the mixture was discharged as a masterbatch. The sulfur and vulcanization accelerator were then added and mixed by an 8-inch open mill to obtain a rubber composition, which was then used for the following tests.

[0056] Test Methods

[0057] 1) Vulcanization rate (ie optimum vulcanization time T95): Measured according to JIS K6300. Measure t at 1 degree amplitude and 160°C with a vibrating disc vulcanization tester 95 time (min). Comparative Example 1 is shown with an index of 100. The smaller the value, the faster the indicated rubber vulcanizes.

[0058] 2) ΔG': αTechnology RPA2000 is commonly used to measure shear stress-strain G'. The unvulcanized rubber prepared above was vulcanized at 160°C for 20 minutes. G' was measured at ...

Embodiment 4~7 and comparative Embodiment 5~7

[0079] Preparation of rubber composition

[0080] The rubber, silica, carbon black, coupling agent, zinc white and other materials except the vulcanization system were mixed for 5 minutes using a 1.8 liter internal Banbury mixer according to Table II below. The mixture was then discharged from the mixer at 150°C and subsequently cooled to room temperature. Thereafter, the mixture was mixed for 5 minutes using a 1.8-liter internal Banbury mixer, discharged at 150° C., and then the vulcanization accelerator and sulfur were mixed in using an open mill. In Example 4, the rubber, silica, carbon black, coupling agent, zinc white and other materials except the vulcanization system were mixed using a 1.8 liter internal Banbury mixer according to Table II below for 10 minute. The mixture was discharged from the mixer at 150°C and then cooled to room temperature. Thereafter, the mixture was again mixed for 10 minutes using a 1.8 liter internal Banbury mixer. The mixture was discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com