Rubber material for wind power generation cable sheath

A rubber material and cable protection technology, applied in the direction of insulated cables, rubber insulators, cables, etc., can solve the problems of poor low temperature resistance and elasticity of wind power cables, unable to meet the requirements of wind power cables, and improve mechanical properties. , High resilience, the effect of avoiding the reduction of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

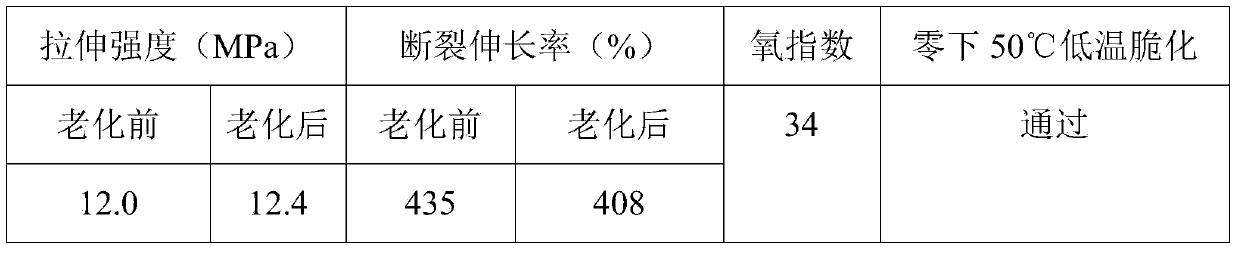

Embodiment 1

[0014] The rubber material for wind power cable sheathing of the present invention, its raw materials include, in parts by weight: 50 parts of chloroprene rubber, 18 parts of cis-butadiene rubber, 32 parts of natural rubber, 15 parts of organically modified montmorillonite, and 1.5 parts of magnesium oxide. parts, zinc oxide 0.8 parts, dicumyl peroxide 1.5 parts, triallyl isocyanurate 0.8 parts, diisobutyl adipate 1 part, ethyl oleate 2.2 parts, hazelnut oil 8 parts , 1.6 parts of stearic acid, 35 parts of carbon black, 10 parts of purple carbon black, 1.5 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 0.5 parts of tetramethylthiuram disulfide, N-isopropyl 1.8 parts of base-N'-phenyl-p-phenylenediamine and 0.4 parts of N-phenyl-2-naphthylamine;

[0015] Wherein, the organically modified montmorillonite is prepared according to the following process: adding 15 parts of sodium-based montmorillonite to 100 parts of water by weight, stirring for 6 hours and then standing for 3...

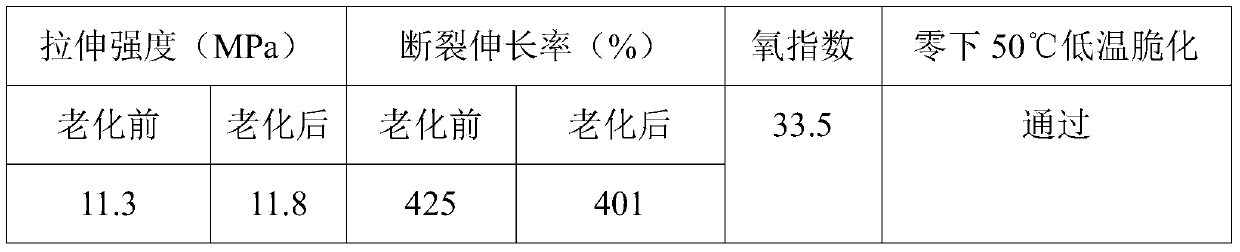

Embodiment 2

[0020] The rubber material for wind power cable sheathing of the present invention, its raw materials include by weight: 70 parts of chloroprene rubber, 10 parts of cis-butadiene rubber, 20 parts of natural rubber, 20 parts of organically modified montmorillonite, 1 part of magnesium oxide parts, zinc oxide 1.3 parts, dicumyl peroxide 2.8 parts, triallyl isocyanurate 0.3 parts, diisobutyl adipate 3 parts, ethyl oleate 0.8 parts, hazelnut oil 5 parts , 1.2 parts of stearic acid, 20 parts of carbon black, 15 parts of purple carbon black, 1.0 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1.6 parts of tetramethylthiuram disulfide, N-isopropyl 2.2 parts of base-N'-phenyl-p-phenylenediamine and 0.8 parts of N-phenyl-2-naphthylamine;

[0021] Wherein, the organically modified montmorillonite is prepared according to the following process: adding 8 parts of sodium-based montmorillonite to 100 parts of water by weight, stirring for 4 hours, and then standing for 30 hours, and taki...

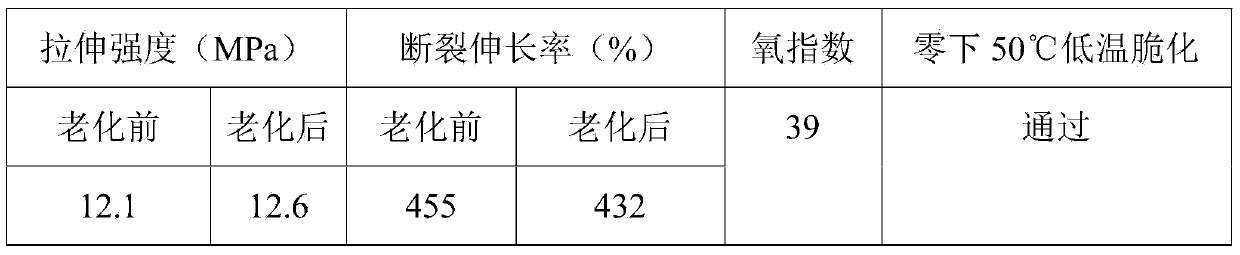

Embodiment 3

[0026] The rubber material for wind power cable sheathing of the present invention includes, in parts by weight, 67 parts of chloroprene rubber, 13 parts of cis-butadiene rubber, 20 parts of natural rubber, 18.2 parts of organically modified montmorillonite, and 1.33 parts of magnesium oxide. parts, zinc oxide 1.05 parts, dicumyl peroxide 1.94 parts, triallyl isocyanurate 0.55 parts, diisobutyl adipate 2.2 parts, ethyl oleate 1.8 parts, hazelnut oil 6.7 parts , 1.38 parts of stearic acid, 32 parts of carbon black, 13.2 parts of purple carbon black, 1.36 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1.38 parts of tetramethylthiuram disulfide, N-isopropyl 2.04 parts of base-N'-phenyl-p-phenylenediamine, 0.65 parts of N-phenyl-2-naphthylamine;

[0027] Wherein, the organically modified montmorillonite is prepared according to the following process: adding 12 parts of sodium-based montmorillonite to 100 parts of water by weight, stirring for 5.2 hours, and then standing for 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com