Environmentally-friendly polyvinyl chloride/nitrile butadiene rubber (PVC/NBR) composite gloves

An environmentally friendly glove technology, applied in the field of composite gloves, can solve the problems of poor wearing suitability, high manufacturing cost, and hard hand feeling of gloves, and achieve the effects of reducing energy consumption, improving wearing comfort, and being completely harmless to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

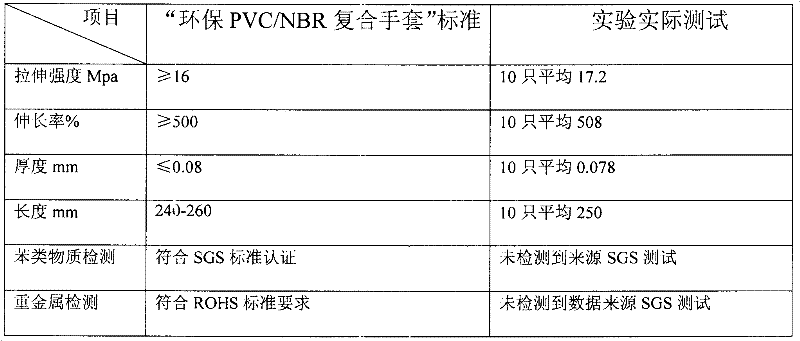

Image

Examples

Embodiment 1

[0022] The first step, according to PVC paste resin powder: ATBC / polyester plasticizer: phenol-free environment-friendly calcium zinc heat stabilizer: nitrile rubber: TMTD / cz accelerator: sulfur: color paste = 100: 40: 0.9: 25 : The ratio of 0.5:0.5:2 selects raw materials for use;

[0023] In the second step, first add ATBC / polyester plasticizer, then add nitrile rubber and phenol-free environment-friendly calcium zinc heat stabilizer, and stir at high speed for 20 minutes;

[0024] The third step is to slowly add PVC paste resin powder, and then stir at high speed for 2 hours;

[0025] In the fourth step, add the vulcanizing agent sulfur and TMTD / cz accelerator, then stir for 20 minutes, and filter the mixed slurry into the sample bucket with a 150-200 mesh stainless steel filter;

[0026] The fifth step is to put the raw materials and the keg into the vacuum drying box at the same time, and use the vacuum pump to carry out vacuum defoaming and slurry preheating, preheating...

Embodiment 2

[0030] The first step, according to PVC paste resin powder: ATBC / polyester plasticizer: phenol-free environment-friendly calcium zinc heat stabilizer: nitrile rubber: TMTD / cz accelerator: sulfur: color paste = 100: 60: 1.8: 40 : The ratio of 1:1:5 is to select raw materials for later use;

[0031] In the second step, first add ATBC / polyester plasticizer, then add nitrile rubber and phenol-free environment-friendly calcium zinc heat stabilizer, and stir at high speed for 30 minutes;

[0032] The third step, slowly add PVC paste resin powder, then stir at high speed for 2.5 hours;

[0033] In the fourth step, add the vulcanizing agent sulfur and TMTD / cz accelerator, then stir for 30 minutes, and filter the mixed slurry into the sample bucket with a 150-200 mesh stainless steel filter;

[0034] The fifth step is to put the raw material and the keg into the vacuum drying box at the same time, and use the vacuum pump to carry out vacuum defoaming and slurry preheating, preheating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com