Reactive rubber composite water-proof roll and production method thereof

A waterproof membrane and production method technology, applied in the direction of rubber layered products, chemical instruments and methods, layered products, etc., can solve the problems of low coil life, low production efficiency, concrete bonding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This reactive rubber composite waterproof membrane is composed of a base layer and a surface layer, the base layer is an EPDM waterproof layer, and the surface layer is a reactive butyl rubber reaction layer;

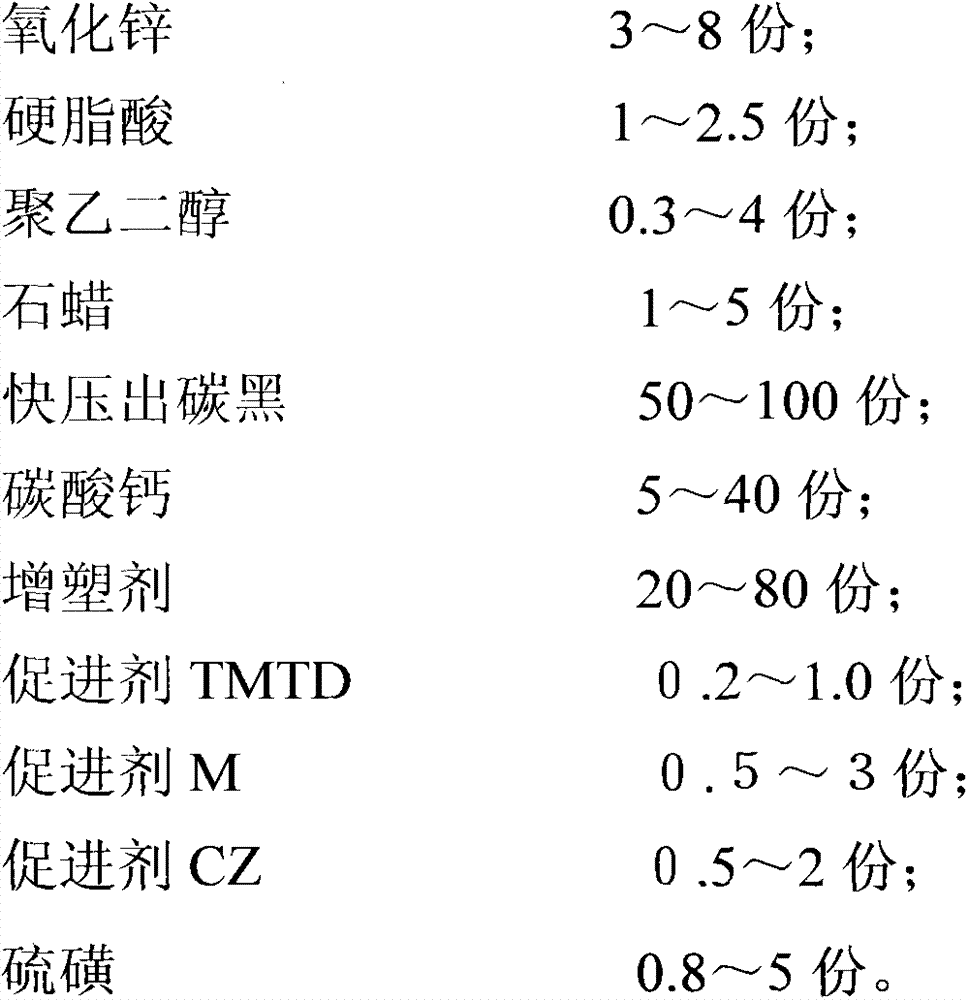

[0055] The proportioning of each component of the base rubber is in parts by weight, based on 100 parts of EPDM rubber, and the content of other components is:

[0056]

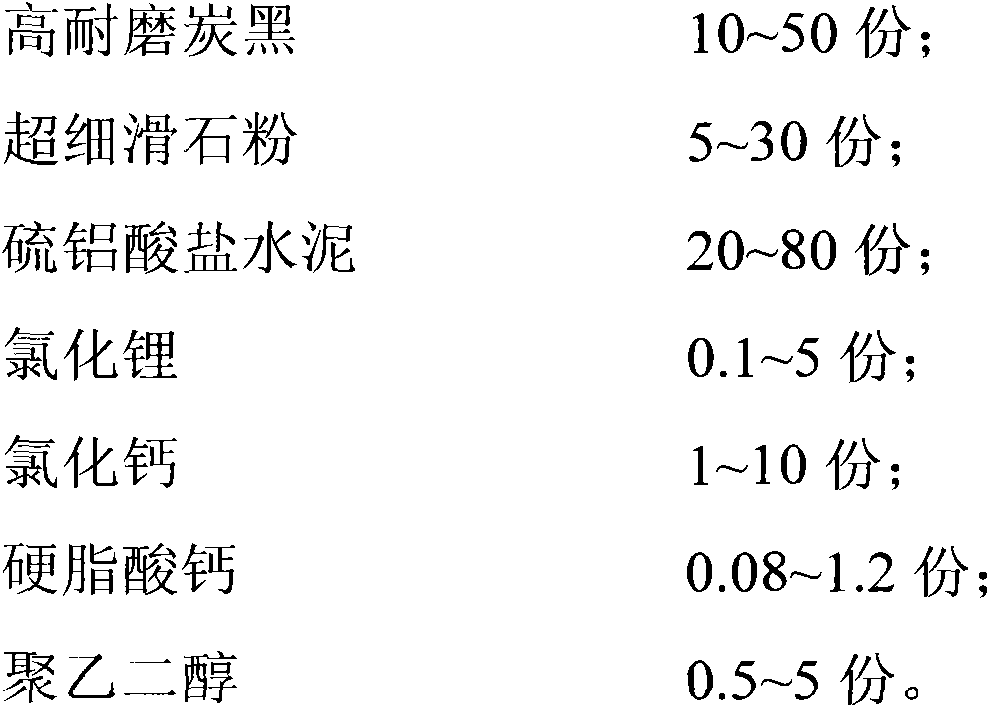

[0057] The proportioning of each component of the surface layer rubber is in parts by weight, based on 100 parts of butyl rubber, and the content of other components is:

[0058]

[0059] In this example, the reactive rubber composite waterproof coiled material is produced by a continuous compounding process. First, the base layer EPDM rubber is extruded and vulcanized; it enters the calender and is compounded with the surface layer butyl rubber, and the composited coiled material is cooled, Trimming, counting, inspection, crimping and packaging are completed continuously and synchronously...

Embodiment 2

[0077] This reactive rubber composite waterproof membrane is composed of a base layer and a surface layer, the base layer is an EPDM waterproof layer, and the surface layer is a reactive butyl rubber reaction layer;

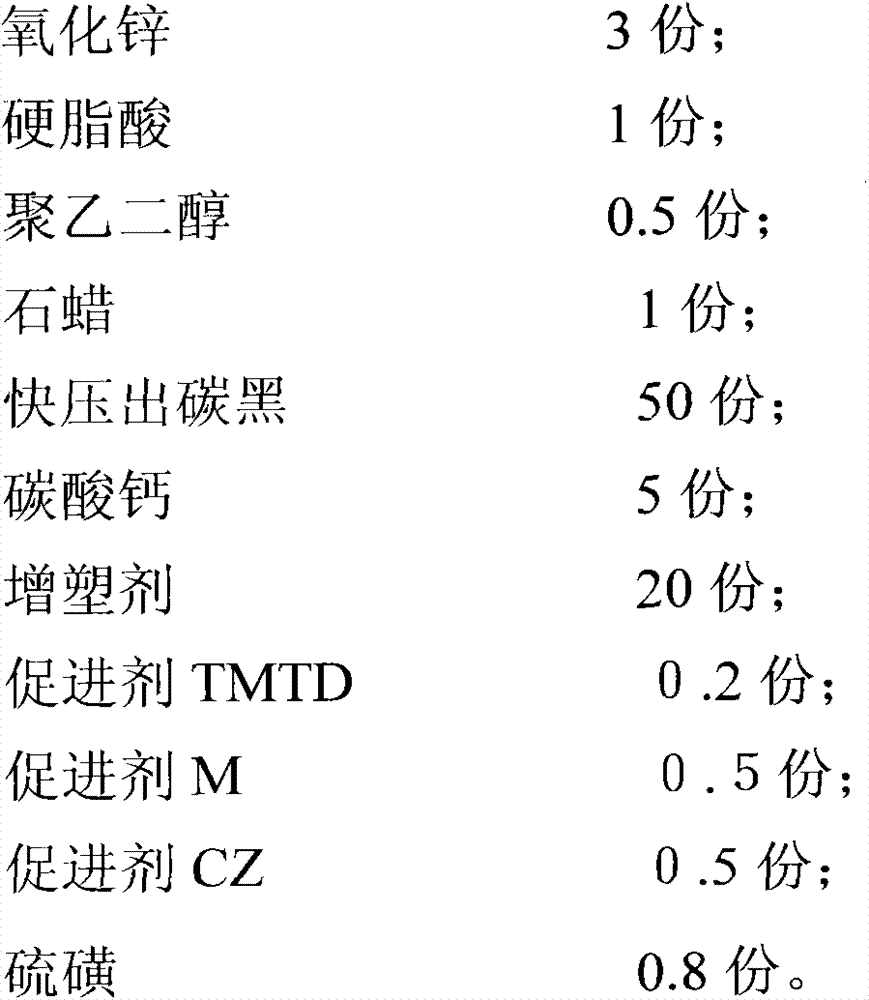

[0078] The proportioning of each component of the base rubber is in parts by weight, based on 100 parts of EPDM rubber, and the content of other components is:

[0079]

[0080] The proportioning of each component of the surface layer rubber is in parts by weight, based on 100 parts of butyl rubber, and the content of other components is:

[0081]

[0082] In this example, the reactive rubber composite waterproof membrane is produced by a segmented composite process, as follows:

[0083] (1), the preparation of base coil

[0084] Put the base compound rubber strip into the extruder; the film formed by the extruder is cut by the thickness measuring device and the edge trimming device to determine the width; after entering the vulcanization device for vulcan...

Embodiment 3

[0102] This reactive rubber composite waterproof membrane is composed of a base layer and a surface layer, the base layer is an EPDM waterproof layer, and the surface layer is a reactive butyl rubber reaction layer;

[0103] The proportioning of each component of the base rubber is in parts by weight, based on 100 parts of EPDM rubber, and the content of other components is:

[0104]

[0105] The proportioning of each component of the surface layer rubber is in parts by weight, based on 100 parts of butyl rubber, and the content of other components is:

[0106]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com