Self-adhesive reactive ethylene-octene copolymer composite waterproof coiled material and production method thereof

A technology of ethylene octene and waterproof membrane, which is applied in the directions of polymer adhesive additives, film/sheet adhesives, non-polymer adhesive additives, etc. High elongation performance, high weather resistance, and the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This self-adhesive reactive ethylene octene copolymer composite waterproof membrane is composed of a base layer, a surface layer, and an anti-adhesive isolation layer. The base layer is an ethylene octene copolymer waterproof layer, and the surface layer is self-adhesive reactive. 丁 Base rubber layer, the isolation layer is PE anti-adhesive isolation film;

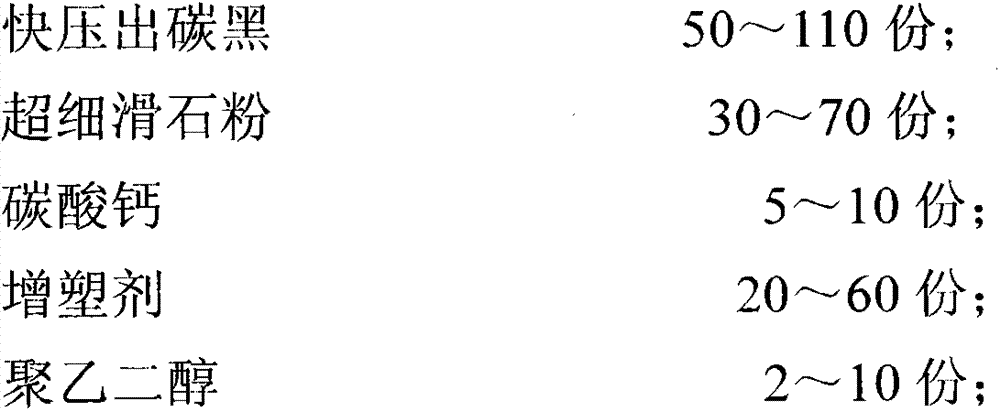

[0045] The proportion of each component of the base rubber is calculated in parts by weight, based on 100 parts of ethylene octene copolymer, and the content of other components is:

[0046]

[0047] The proportioning of each component of the surface layer rubber is in parts by weight, based on 100 parts of butyl rubber, and the content of other components is:

[0048]

[0049] In this example, the self-adhesive reactive ethylene octene copolymer composite waterproof membrane is produced by an on-line continuous composite process. First, the base layer ethylene octene copolymer is extruded and vulcanized; it d...

Embodiment 2

[0067] This self-adhesive reactive ethylene octene copolymer composite waterproof membrane is composed of a base layer, a surface layer, and an anti-adhesive isolation layer. The base layer is an ethylene octene copolymer waterproof layer, and the surface layer is a self-adhesive reactive butyl Rubber layer, the isolation layer is PE anti-adhesive isolation film;

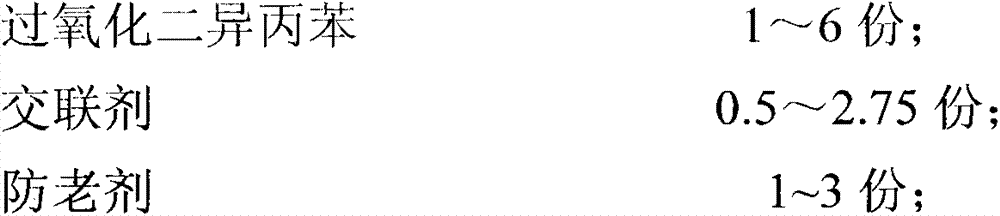

[0068] The proportion of each component of the base rubber is calculated in parts by weight, based on 100 parts of ethylene octene copolymer, and the content of other components is:

[0069]

[0070] The proportioning of each component of the surface layer rubber is in parts by weight, based on 100 parts of butyl rubber, and the content of other components is:

[0071]

[0072] In this example, the self-adhesive reactive ethylene octene copolymer composite waterproof membrane is produced by an online continuous composite process, as follows:

[0073] a. Rubber mixing,

[0074] (1) Put the components of the b...

Embodiment 3

[0090] This self-adhesive reactive ethylene octene copolymer composite waterproof membrane is composed of a base layer, a surface layer, and an anti-adhesive isolation layer. The base layer is an ethylene octene copolymer waterproof layer, and the surface layer is a self-adhesive reactive butyl Rubber layer, the isolation layer is PE anti-adhesive isolation film;

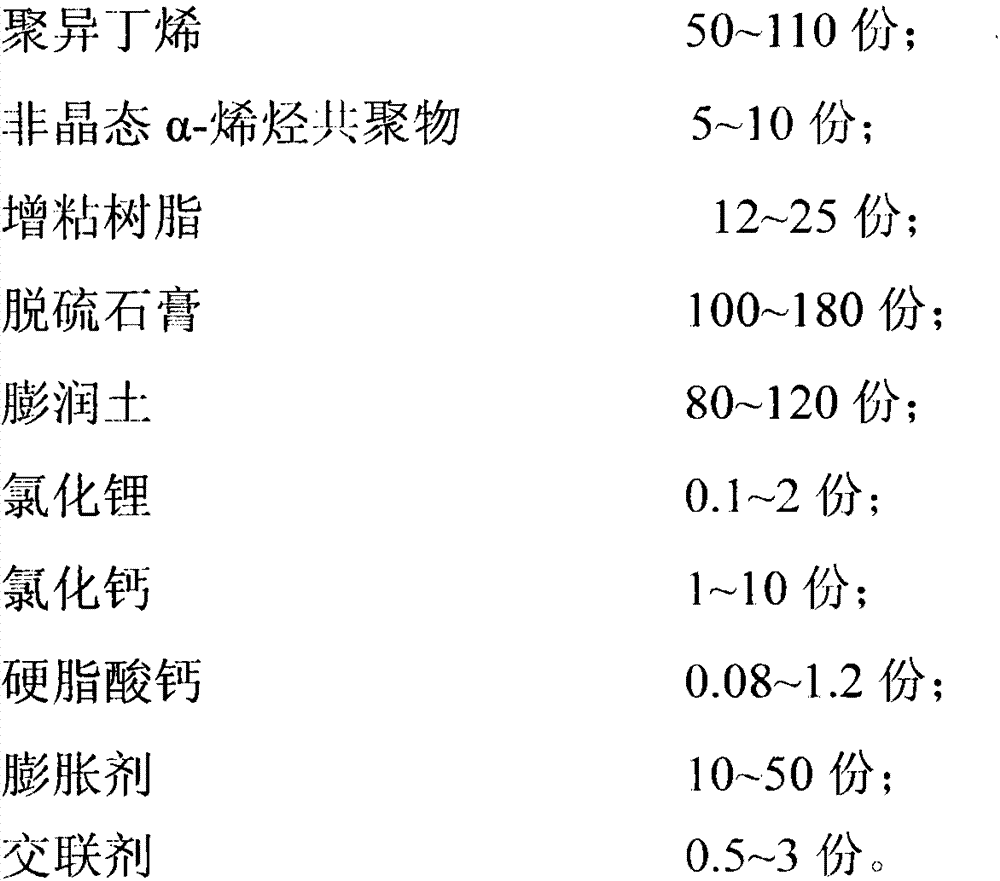

[0091] The proportion of each component of the base rubber is calculated in parts by weight, based on 100 parts of ethylene octene copolymer, and the content of other components is:

[0092]

[0093] The proportioning of each component of the surface layer rubber is in parts by weight, based on 100 parts of butyl rubber, and the content of other components is:

[0094]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com