A kind of self-adhesive reactive EPDM composite waterproof membrane and production method thereof

A technology of EPDM rubber and waterproof membrane, which is applied in rubber layered products, chemical instruments and methods, layered products, etc., can solve the problem that the material cannot repair itself, and achieve the effect of high elongation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This self-adhesive reactive EPDM composite waterproof membrane is composed of base layer, surface layer and anti-adhesive isolation layer. The base layer is EPDM waterproof layer, and the surface layer is self-adhesive reactive butyl Rubber layer, anti-adhesive isolation layer is PE anti-adhesive isolation film;

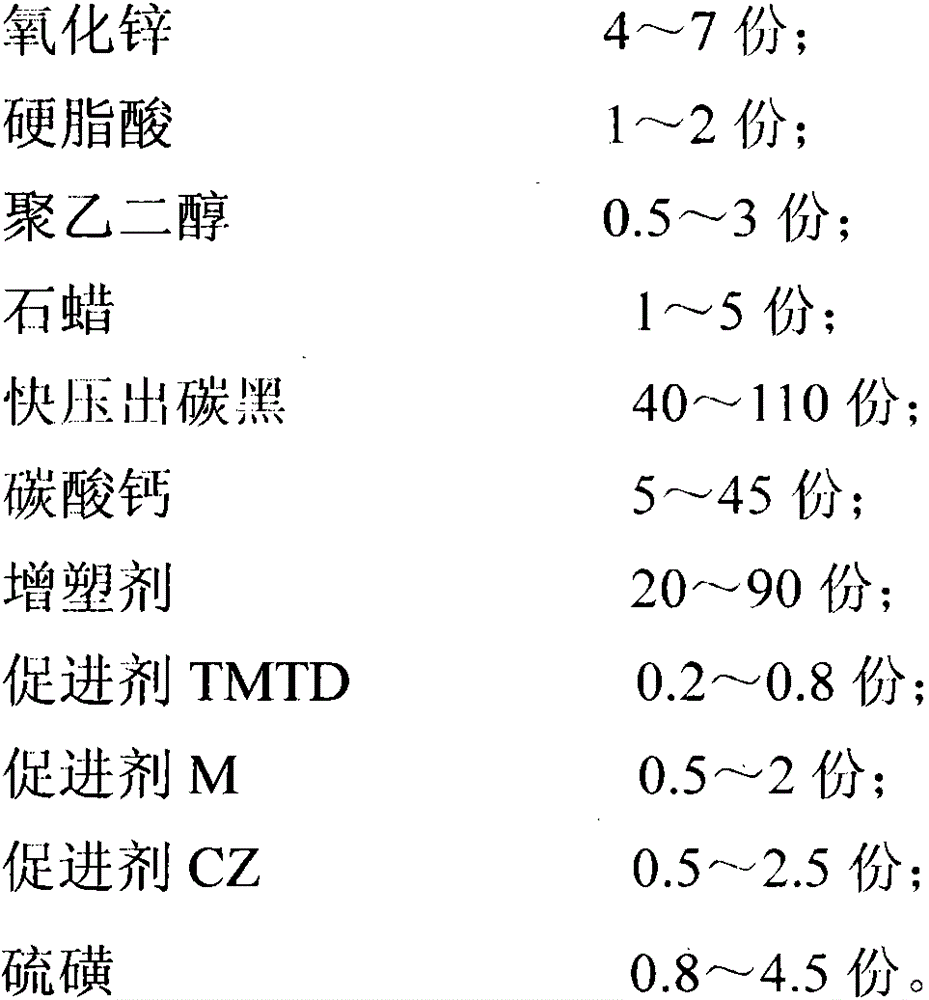

[0045] The proportion of each component of the base rubber is in parts by weight, based on 100 parts of EPDM rubber, and the content of other components is:

[0046]

[0047]

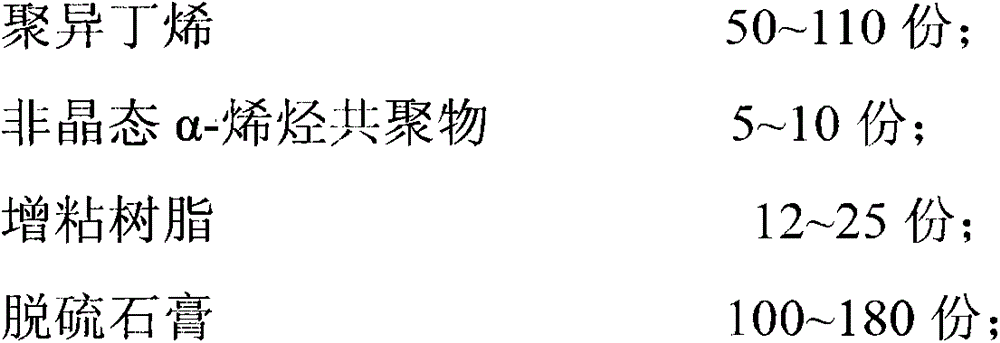

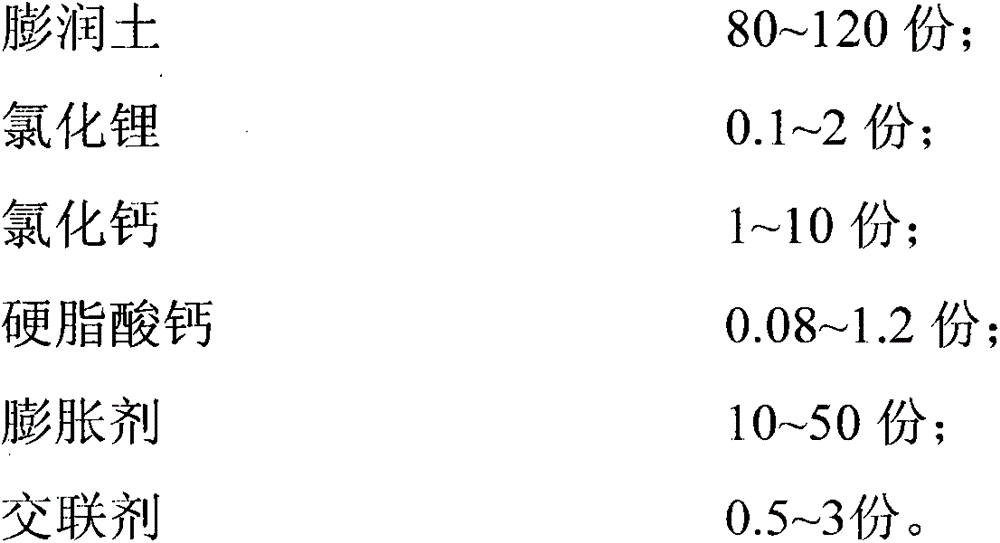

[0048] The proportioning of each component of the surface layer rubber is in parts by weight, based on 100 parts of butyl rubber, and the content of other components is:

[0049]

[0050] In this embodiment, the self-adhesive reactive EPDM composite waterproof membrane is produced by an online continuous composite process. First, the base-layer EPDM rubber is extruded and vulcanized; it directly enters the composite machine and the surface layer self-adhesive reactive butyl Base...

Embodiment 2

[0068] This self-adhesive reactive EPDM composite waterproof membrane is composed of base layer, surface layer and anti-adhesive isolation layer. The base layer is EPDM waterproof layer, and the surface layer is self-adhesive reactive butyl Rubber layer, anti-adhesive isolation layer is PE anti-adhesive isolation film;

[0069] The proportion of each component of the base rubber is in parts by weight, based on 100 parts of EPDM rubber, and the content of other components is:

[0070]

[0071]

[0072] The proportioning of each component of the surface layer rubber is in parts by weight, based on 100 parts of butyl rubber, and the content of other components is:

[0073]

[0074] In this example, the self-adhesive reactive EPDM composite waterproof membrane is produced by an online continuous composite process, as follows:

[0075] a. Rubber mixing,

[0076] (1) Put the components of the base material into the internal mixer according to the weight percentage for mix...

Embodiment 3

[0092] This self-adhesive reactive EPDM composite waterproof membrane is composed of base layer, surface layer and anti-adhesive isolation layer. The base layer is EPDM waterproof layer, and the surface layer is self-adhesive reactive butyl Rubber layer, anti-adhesive isolation layer is PE anti-adhesive isolation film;

[0093] The proportion of each component of the base rubber is in parts by weight, based on 100 parts of EPDM rubber, and the content of other components is:

[0094]

[0095] The proportioning of each component of the surface layer rubber is in parts by weight, based on 100 parts of butyl rubber, and the content of other components is:

[0096]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com