Rubber composition with low temperature resistance, grease resistance and high temperature resistance, preparation method, use and application product thereof

A technology of rubber composition and low temperature resistance, which is applied in the field of rubber composition, and can solve the problems that nitrile rubber cannot meet oil resistance and high temperature and low temperature resistance at the same time, and achieve the effect of low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

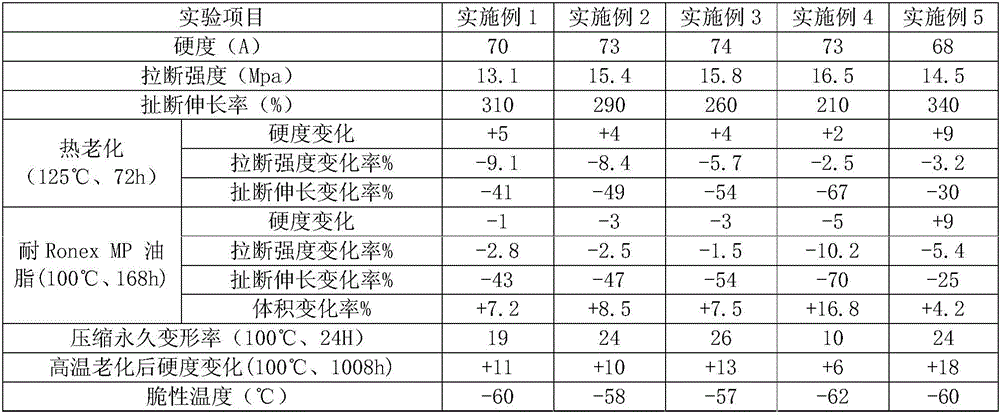

Examples

Embodiment

[0028] The preparation method using the low temperature resistance, grease resistance and high temperature resistance rubber composition disclosed by the present invention comprises the following steps:

[0029] 1. Take the nitrile rubber of the formula amount, and add the formula amount of magnesium oxide, zinc oxide, stearic acid, magnesium methacrylate in turn after passing through the thin pass to be wrapped; then add half of the formula amount of carbon black; then add the formula in turn Amount of flow aid WB222, anti-aging agent 445 and ZMMBI, plasticizer; then add half of the formula amount of carbon black; finally add dicumyl peroxide, tetramethylthiuram disulfide, 4-4'-di Dimorpholine sulfide;

[0030] 2. Kneading the mixture processed in step 1;

[0031] 3. Place the mixture treated in step 2 for one day.

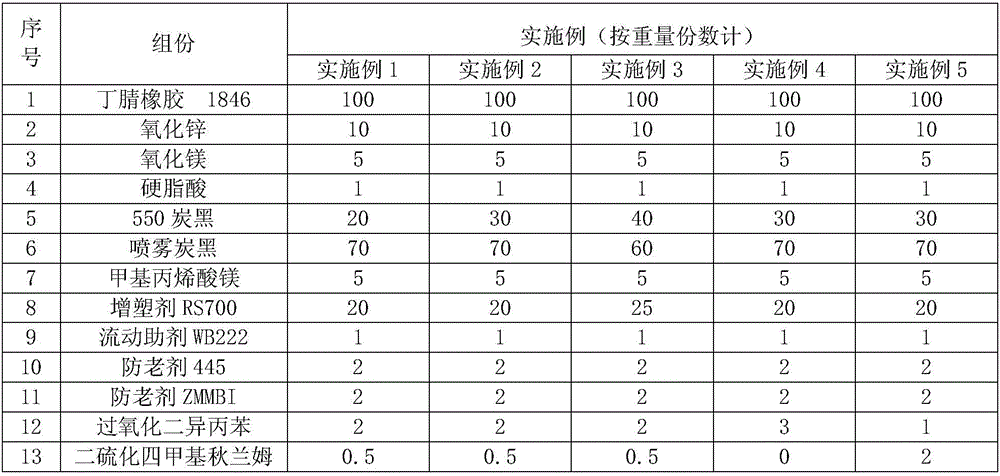

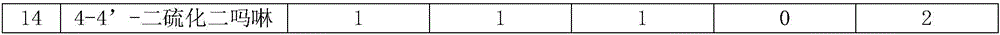

[0032] A rubber composition resistant to low temperature, grease and high temperature has been prepared, and its specific ratio is as follows:

[0033]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com