Anode material for lithium-sulfur batteries and preparation method of anode material

A technology of sulfur battery and positive electrode slurry, applied in the field of electrochemical battery, can solve problems such as low Coulomb effect, loss of active material, corrosion of lithium negative electrode, etc., achieve high reversible specific capacity, solve poor reversibility, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

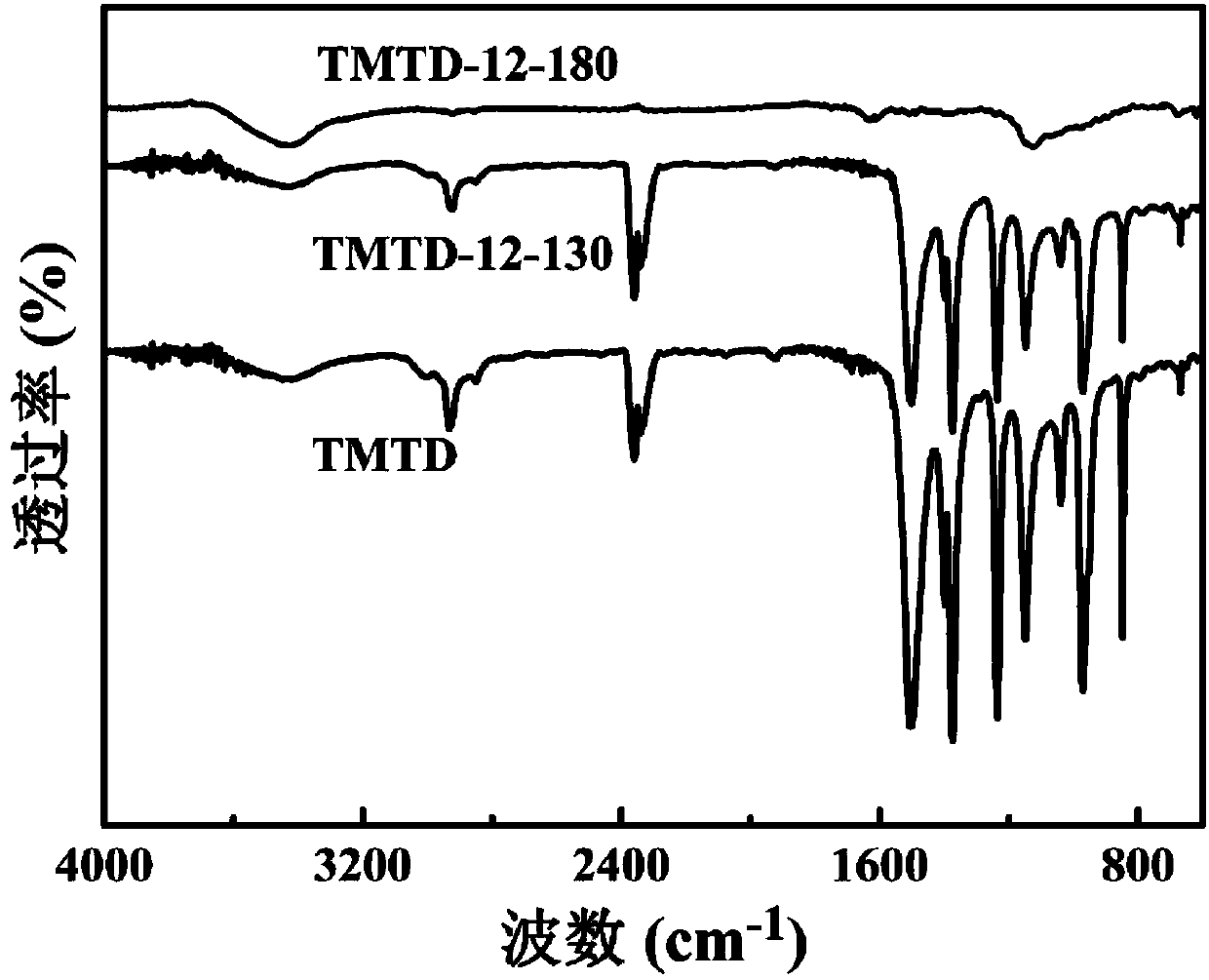

[0019] TMTD-12-120 was prepared by using TMTD as the sulfur source, heating to 120 ℃ and holding it for 12 h.

[0020] Take TMTD-12-120 as the active material, mix it with the conductive agent acetylene black, and the binder polyvinylidene fluoride at a mass ratio of 7:2:1, use N-methyl-2-pyrrolidone as the solvent, stir evenly and then coat on the aluminum foil of the current collector, and then dried in a vacuum oven at 70 °C for 12 h, and set aside.

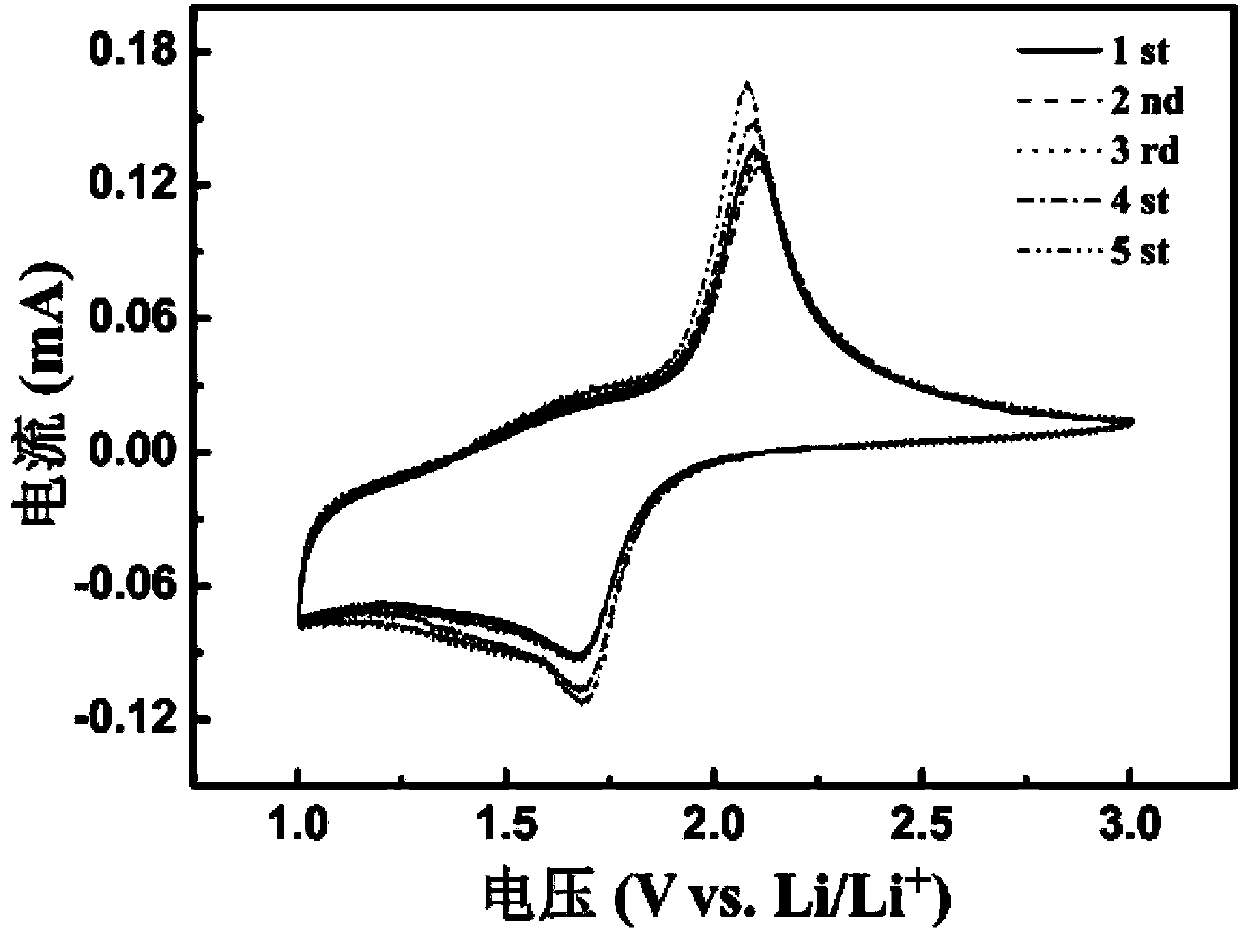

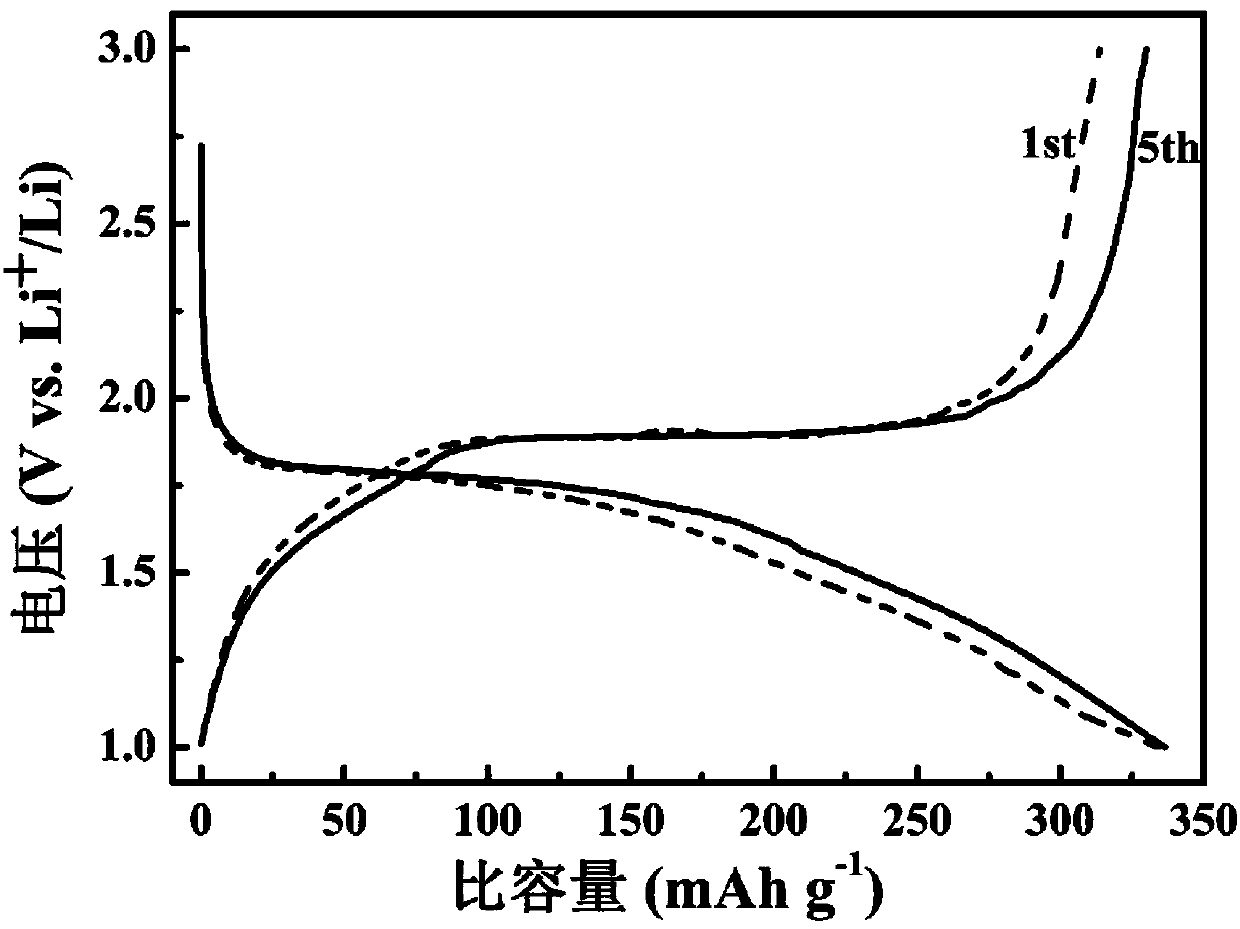

[0021] Lithium sheet as the negative electrode, PP as the diaphragm, using 1 mol / L LiTFSI and 0.1 mol / L LiNO 3 / DOL+DME (dioxolane and ethylene glycol dimethyl ether, volume ratio 1:1) is the electrolyte and assembled into a battery. The battery was first charged and discharged at a current density of 20 mA / g, and the voltage range was 1.0-3.0 V. The initial discharge capacity was 247 mAh / g, and the capacity retention was 60% after 10 cycles.

Embodiment 2

[0023] TMTD-12-140 was prepared by heating to 140 °C and keeping it warm for 12 h with TMTD as the sulfur source. The preparation method of the positive electrode sheet and the battery assembly method were the same as in Example 1. The initial discharge capacity was 166 mAh / g, and the capacity retention was 10% after 10 cycles.

Embodiment 3

[0025] TMTD-12-160 was prepared by heating to 160 °C and keeping it warm for 12 h with TMTD as the sulfur source. The preparation method of the positive electrode sheet and the battery assembly method were the same as in Example 1. The initial discharge capacity was 253 mAh / g, and the capacity retention was 6% after 10 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com