Pneumatic radial tire capable of promoting wetland grip performance

A radial tire and grip technology, which is applied to the reinforcement layer of pneumatic tires, tire parts, tire edges, etc., can solve the problems of improving wet grip, achieve excellent handling performance, and improve the wet grip performance of tires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

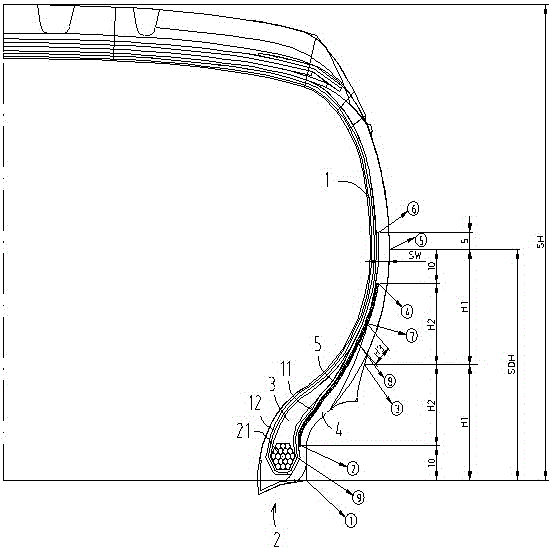

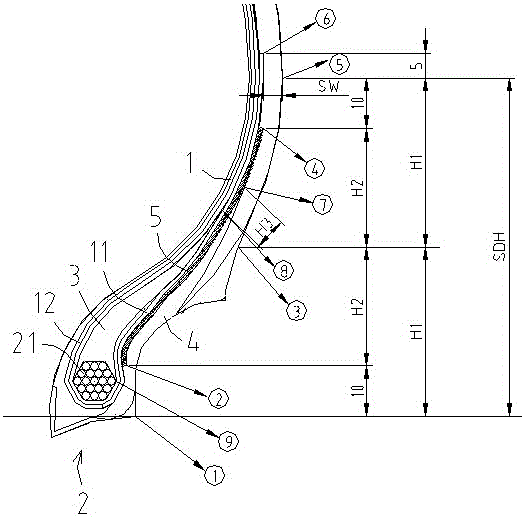

[0021] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] Such as figure 1 and 2 As shown, the pneumatic radial tire includes a carcass layer 1 and a bead portion 2, wherein the bead portion 2 has a single steel wire bead inside and is formed with a bead core 21, and the carcass layer 1 is wound around the bead core Turned up from inside to outside, the carcass layer 1 is composed of a main body portion 11 and a turned up portion 12, an apex 3 is arranged between the main body portion and the turned up portion, and the tire axially outer side of the turned up portion is arranged There are mouth protection glue 4. Between the axially outer side of the turn-up portion 12 of the carcass layer and the axially inner side of the spigot rubber 4, a sidewall reinforcing layer 5 (shaded in the drawing) is arranged along the turn-up portion. part).

[0023] figure 1 The reference sign ① in the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com