Rubber composition for tire and pneumatic tire

A rubber composition and rubber technology are applied in the field of rubber compositions for tires and pneumatic tires, which can solve the problems of reduced performance, increased hardness, inability to improve wet grip performance, etc., and achieve improved elongation at break and improved wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

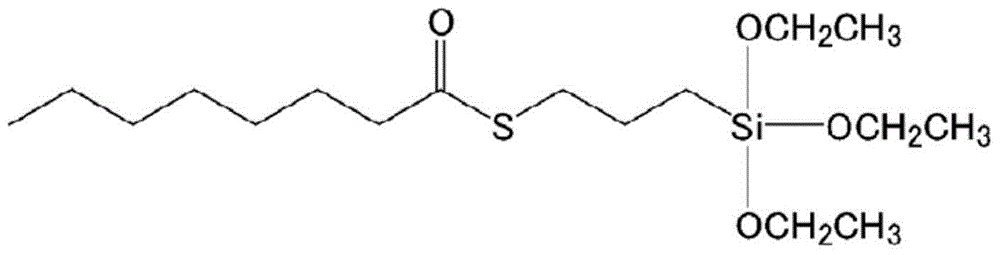

[0076] 18 L of n-hexane, 740 g of styrene (manufactured by KANTO CHEMICAL Co., Ltd.), 1260 g of butadiene, and 10 mmol of tetramethylethylenediamine were added to a 30 L pressure vessel fully purged with nitrogen, and the temperature was heated to 40°C. Next, 10 ml of butyllithium was added thereto, and then, the temperature was raised to 50° C., and the mixture was stirred for 3 hours. Next, 11 ml of the above-mentioned terminal modifier was added to the mixture, and the mixture was stirred for 30 minutes. 15 ml of methanol and 0.1 g of 2,6-tert-butyl-p-cresol were added to the reaction solution. Subsequently, the reaction solution was poured into a stainless steel container containing 18 L of methanol, thereby collecting aggregates. The obtained aggregate was dried under reduced pressure for 24 hours to obtain a modified SBR.

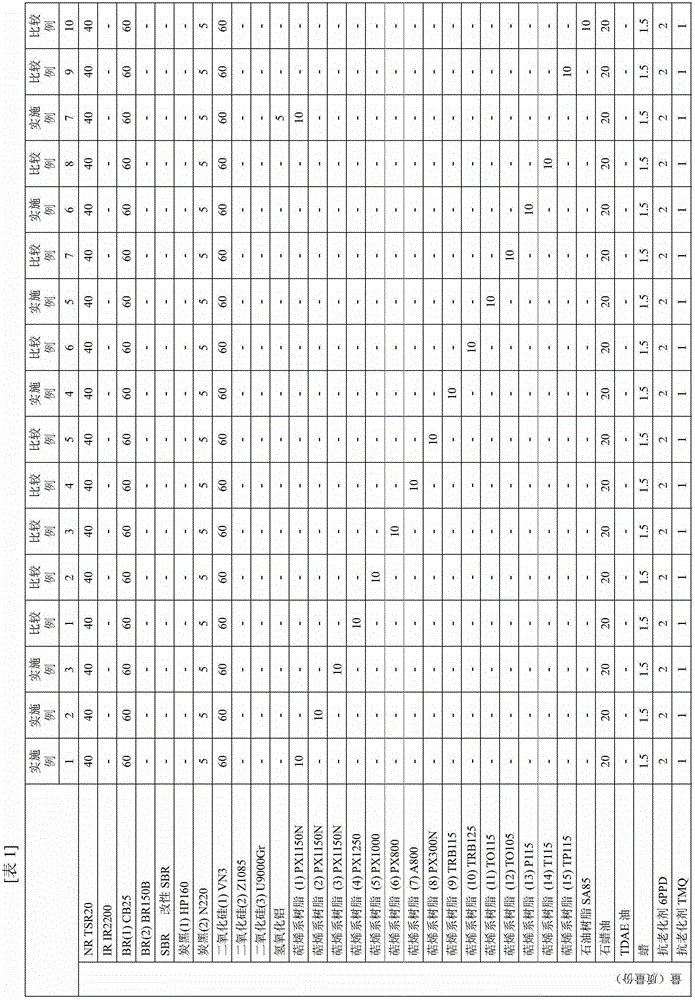

[0077] Hereinafter, various chemicals used in Examples and Comparative Examples will be collectively explained. The terpene-based resins (1) to (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com