Rubber composition and tire

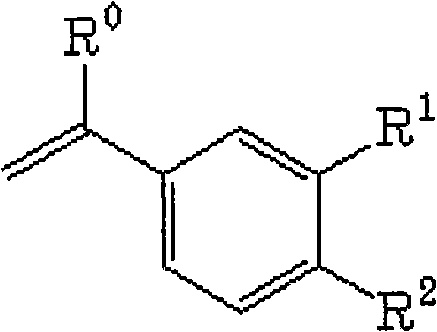

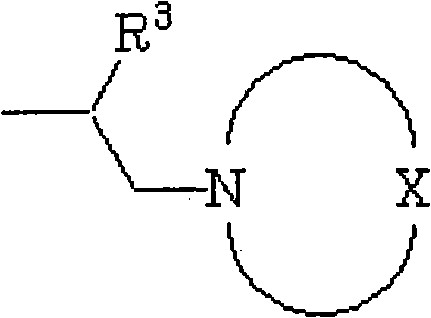

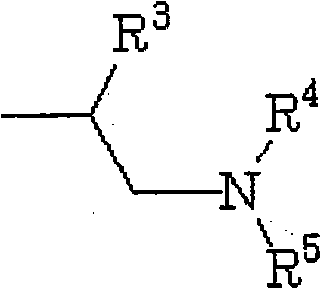

A rubber composition and rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of insufficient improvement and low heat generation, and achieve the effect of good wet grip performance and low heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0474] Next, the present invention will be specifically described based on examples, but the present invention is not limited to these examples.

[0475] Each chemical used in the synthesis of the monomer (1) is listed below.

[0476] Cyclohexane: Cyclohexane (manufactured by Kanto Chemical Co., Ltd.)

[0477] Pyrrolidine: pyrrolidine (manufactured by Kanto Chemical Co., Ltd.)

[0478] Divinylbenzene: divinylbenzene (manufactured by Sigma-Aldrich Japan K.K.)

[0479] 1.6M hexane solution of n-butyllithium: 1.6M hexane solution of n-butyllithium (manufactured by Kanto Chemical Co., Ltd.)

[0480] Isopropyl alcohol: Isopropyl alcohol (manufactured by Kanto Chemical Co., Ltd.)

manufacture example 1

[0481] Production Example 1 (Synthesis of Monomer (1))

[0482] To a 100 ml container in which the air was sufficiently replaced with nitrogen, 50 ml of cyclohexane, 4.1 ml (3.6 g) of pyrrolidine, and 6.5 g of divinylbenzene were added. At 0° C., 0.7 ml of a 1.6 M n-butyllithium hexane solution was further added thereto, and the mixture was stirred. After 1 hour, isopropanol was added to the mixture to stop the reaction, followed by extractive purification to obtain monomer (1).

[0483] The respective chemicals used in the synthesis of polymers (1) and (2) are listed below.

[0484] Cyclohexane: Cyclohexane (manufactured by Kanto Chemical Co., Ltd.)

[0485] Styrene: Styrene (manufactured by Kanto Chemical Co., Ltd.)

[0486] Butadiene: 1,3-butadiene (manufactured by Takachiho Chemical Industry Co., Ltd.)

[0487] Tetramethylethylenediamine: N, N, N', N'-tetramethylethylenediamine (manufactured by Kanto Chemical Co., Ltd.)

[0488] 1.6M hexane solution of n-butyllithium:...

manufacture example 2

[0491] Production Example 2 (Synthesis of Polymer (1))

[0492] Into the 1000ml pressure-resistant vessel in which the air was fully replaced by nitrogen, 600ml of cyclohexane, 12.6ml (11.4g) of styrene, 71.0ml (41.0g) of butadiene, 0.29g of monomer (1), and 0.11 ml tetramethylethylenediamine. At 40° C., 0.2 ml of a 1.6 M n-butyllithium hexane solution was further added thereto, and the mixture was stirred. After 3 hours, 3 ml of isopropanol was added to the mixture to stop the polymerization. After adding 1 g of 2,6-tert-butyl-p-cresol to the reaction solution, the solution was subjected to reprecipitation treatment with methanol, and heat-dried to obtain a polymer (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com