Producing method of pneumatic tire

A technology for pneumatic tires and a manufacturing method, which is applied to tire parts, tire treads/tread patterns, tires, etc., can solve the problem of difficulty in setting conductive through terminals, etc., and achieve the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

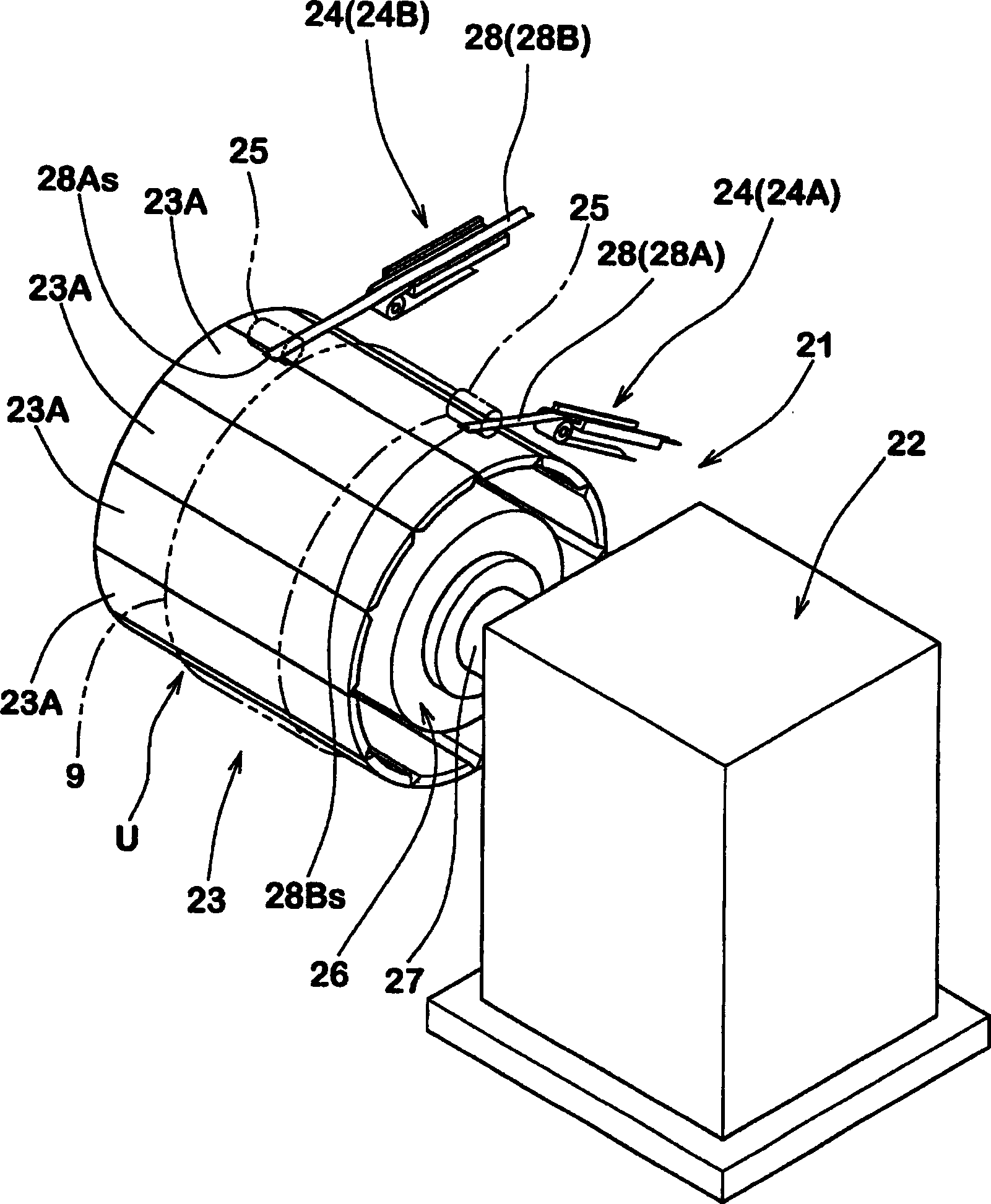

[0031] An embodiment of the present invention will be described below based on the drawings.

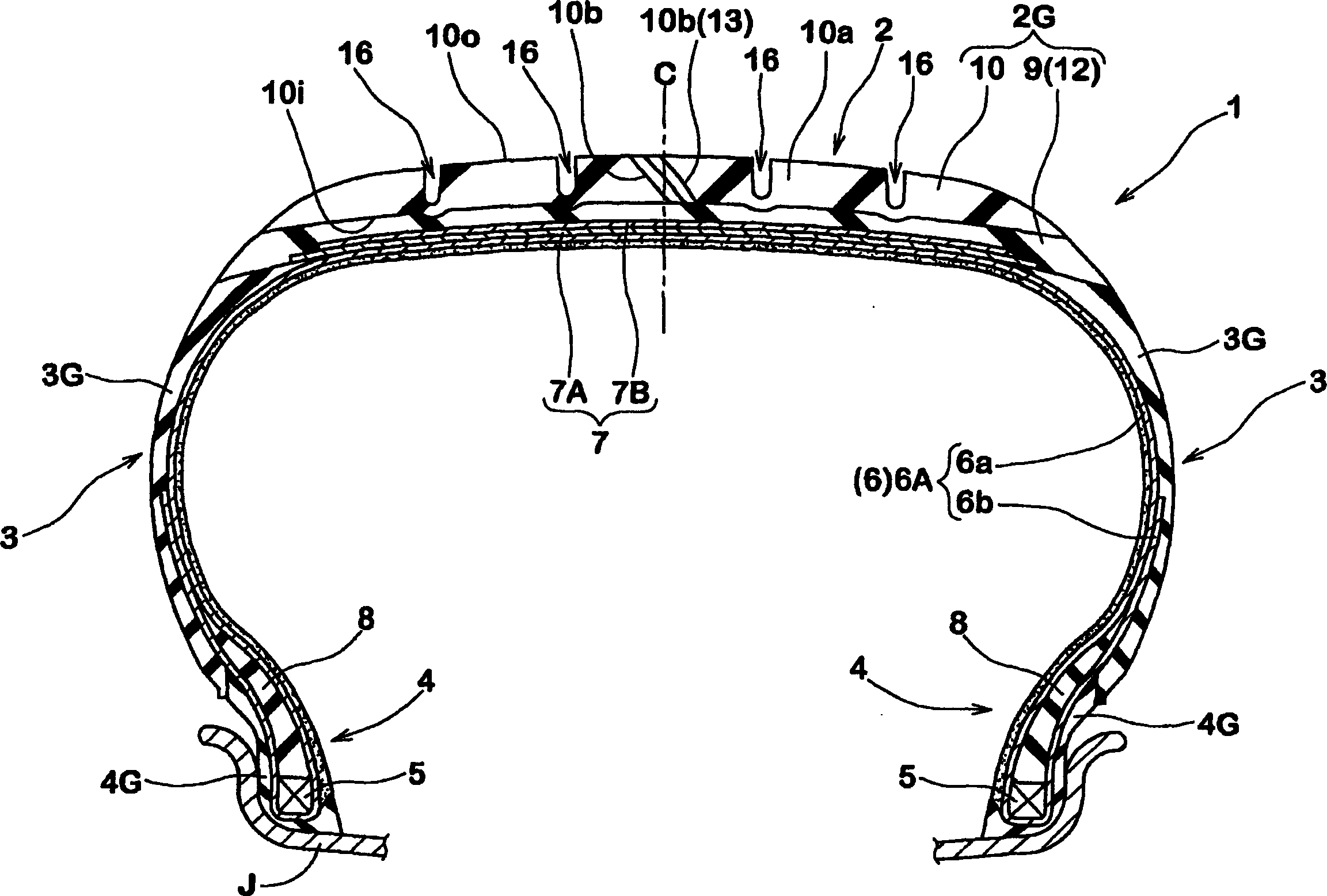

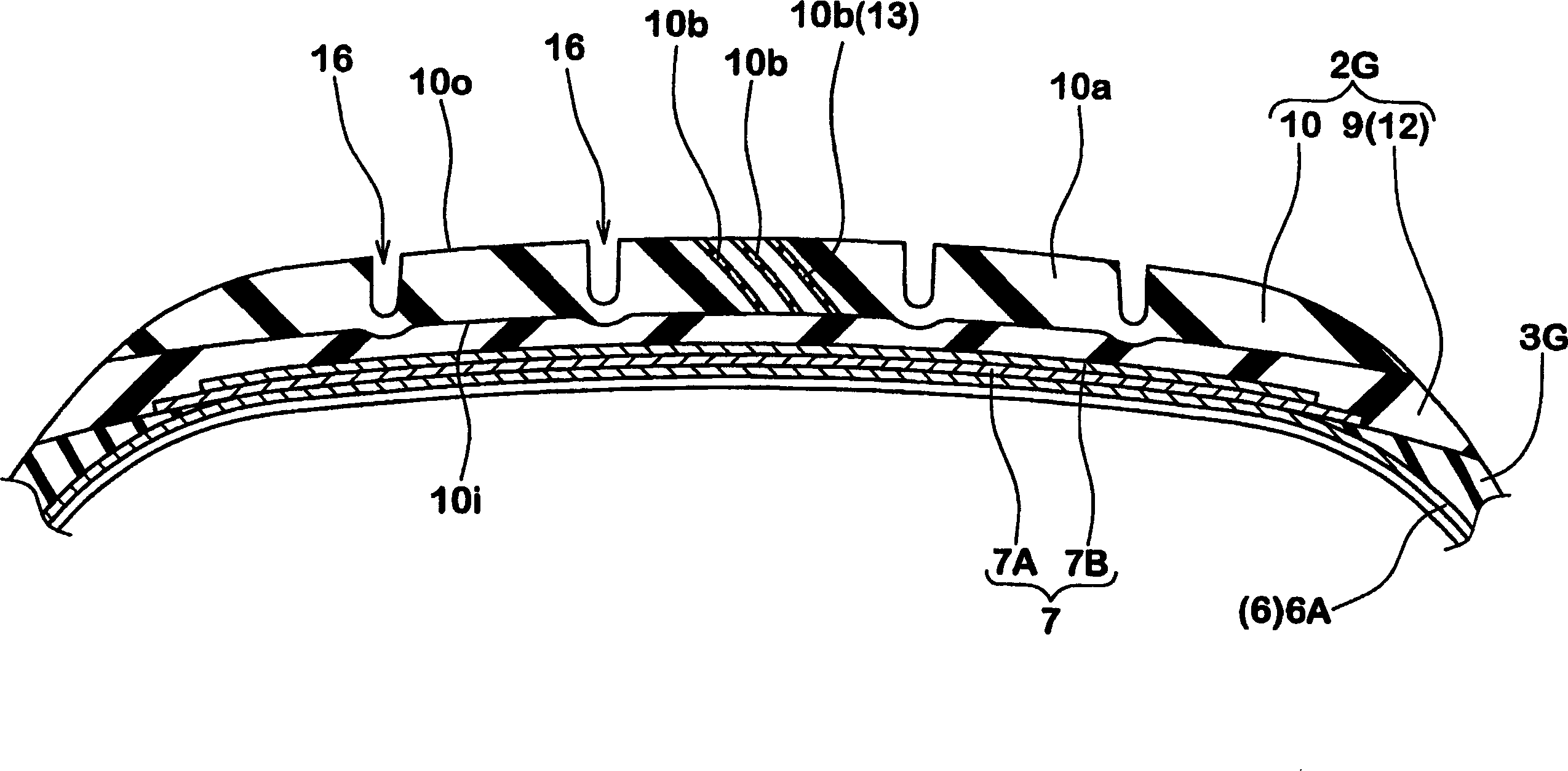

[0032] figure 1 is a cross-sectional view of a pneumatic tire 1 manufactured by the method of the present invention. The pneumatic tire 1 includes: an annular carcass 6 extending from the tread portion 2 to the bead core 5 of the bead portion 4 via the sidewall portion 3; outside and on the inside of the tread portion 2.

[0033] The carcass 6 includes, for example, a carcass ply 6A of radial structure. The carcass ply 6A includes, for example, an annular main body portion 6 a extending between the bead cores 5 and 5 , and a pair of turned-back portions 6 b continuously extending from both sides of the main body portion 6 a around the bead core 5 . Fold the tire axially from the inside to the outside. A bead apex 8 extending radially outward from the bead core 5 is arranged between the main body portion 6 a and the turnback portion 6 b of the carcass ply 6A.

[0034] The tread r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com