Rubber composition and pneumatic tire

A rubber composition, rubber technology, applied in the direction of special tires, tire parts, transportation and packaging, etc., to achieve the effect of balance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

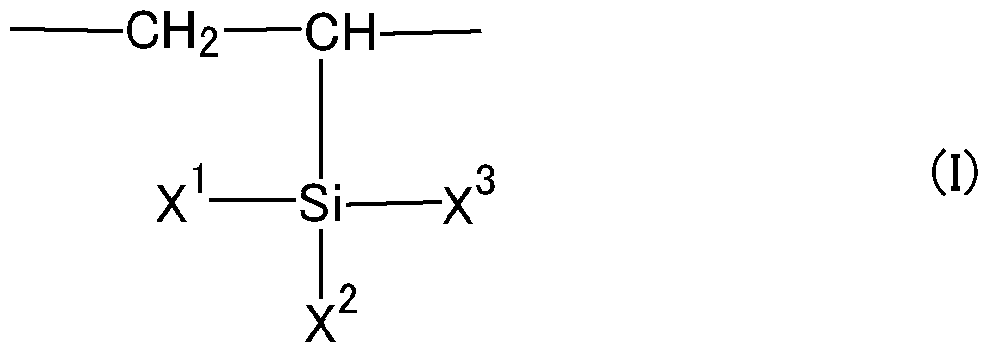

[0310] Production Example 1 (Synthesis of Polymer 1)

[0311] Wash and dry the stainless steel polymerization reactor with an inner volume of 20 liters, replace with dry nitrogen, and hexane (specific gravity 0.68g / cm 3 ) 10.2kg, 547g of 1,3-butadiene, 173g of styrene, 6.1ml of tetrahydrofuran, and 5.0ml of ethylene glycol diethyl ether were put into the polymerization reaction vessel. Next, 16.0 mmol of bis(diethylamino)methylvinylsilane was made into a cyclohexane solution, and 18.5 mmol of n-butyllithium was made into a n-hexane solution, and were added into a polymerization reaction vessel to start polymerization.

[0312] Copolymerization of 1,3-butadiene and styrene was carried out for 3 hours while the stirring rate was set at 130 rpm and the temperature in the polymerization reactor was 65° C., while continuously supplying monomers into the polymerization reactor. The supplied amount of 1,3-butadiene for the entire polymerization was 821 g, and the supplied amount of ...

manufacture example 2

[0315] Production Example 2 (Synthesis of Polymer 2)

[0316] Wash and dry the stainless steel polymerization reactor with an inner volume of 20 liters, replace with dry nitrogen, and hexane (specific gravity 0.68g / cm 3 ) 10.2kg, 547g of 1,3-butadiene, 173g of styrene, 6.1ml of tetrahydrofuran, and 5.0ml of ethylene glycol diethyl ether were added to the polymerization reaction vessel. Next, a n-hexane solution of 17.3 mmol of n-butyllithium was added to carry out copolymerization of 1,3-butadiene and styrene for 1 hour. During the polymerization, the stirring rate was set at 130 rpm and the temperature in the polymerization reactor was 65° C., and the monomer was continuously supplied into the polymerization reaction container.

[0317] After the 1-hour polymerization, a cyclohexane solution of 14.4 mmol of bis(diethylamino)methylvinylsilane was charged into the polymerization reactor at a stirring rate of 130 rpm and a polymerization reactor internal temperature of 65°C.

...

manufacture example 3(

[0325] Production Example 3 (Synthesis of Polymer 3)

[0326] Wash and dry the stainless steel polymerization reactor with an inner volume of 5 liters, replace with dry nitrogen, and hexane (specific gravity 0.68g / cm 3 ) 2.55kg, 137g of 1,3-butadiene, 43g of styrene, 1.5ml of tetrahydrofuran, and 1.2ml of ethylene glycol diethyl ether were added to the polymerization reaction vessel. Next, 3.6 mmol of n-butyllithium was made into a n-hexane solution and put into a polymerization reaction vessel, and copolymerization of 1,3-butadiene and styrene was carried out for 2.5 hours. During the polymerization, the stirring speed was set at 130 rpm and the temperature in the polymerization reactor was 65° C., and the monomer was continuously supplied into the polymerization reactor. The supplied amount of 1,3-butadiene was 205 g, and the supplied amount of styrene was 65 g.

[0327] After the 2.5-hour polymerization, 2.8 mmol of bis(diethylamino)methylvinylsilane was made into a cyclo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com