Rubber composition for tire tread and tire manufactured using same

一种橡胶组合物、轮胎胎面的技术,应用在用于轮胎胎面的橡胶组合物和使用其制造的轮胎领域,能够解决制动性能降低、降低制动性能和调整稳定性能、低油耗性能不利等问题,达到低油耗性能、良好油耗性能、改善制动性能和操纵性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

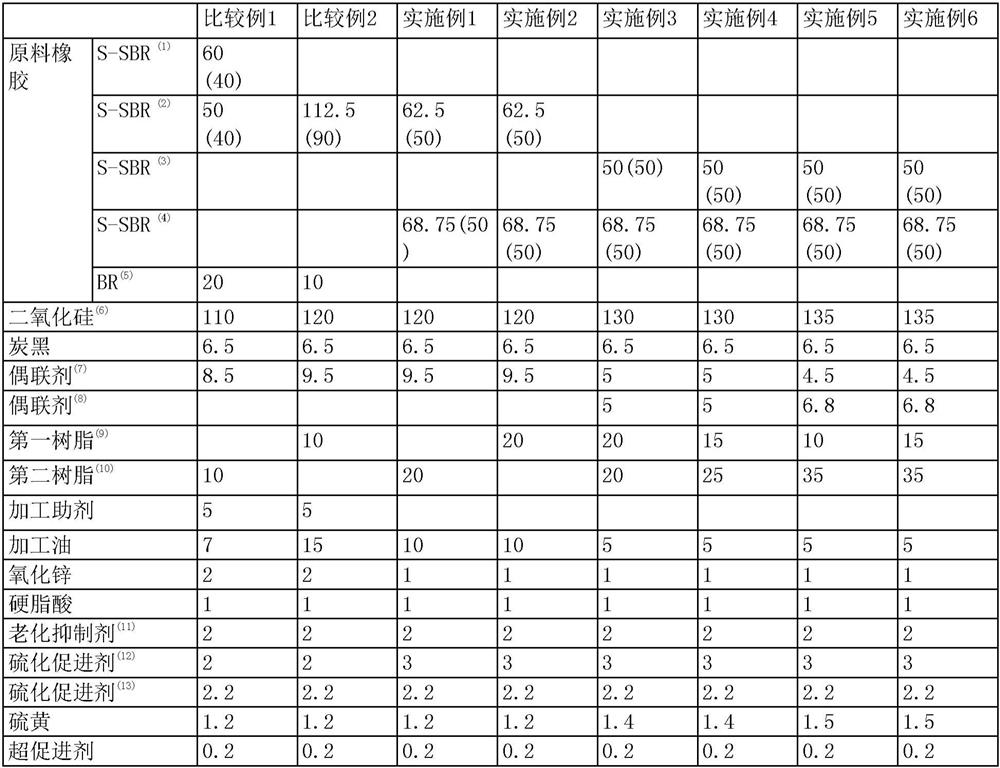

[0114] [Preparation Example: Preparation of Rubber Composition]

[0115] Rubber compositions for tire treads according to the following Examples and Comparative Examples were prepared using the components shown in Table 1 below. The above-mentioned rubber composition is prepared by a usual method for preparing a rubber composition.

[0116] Table 1

[0117]

[0118]

experiment example 1

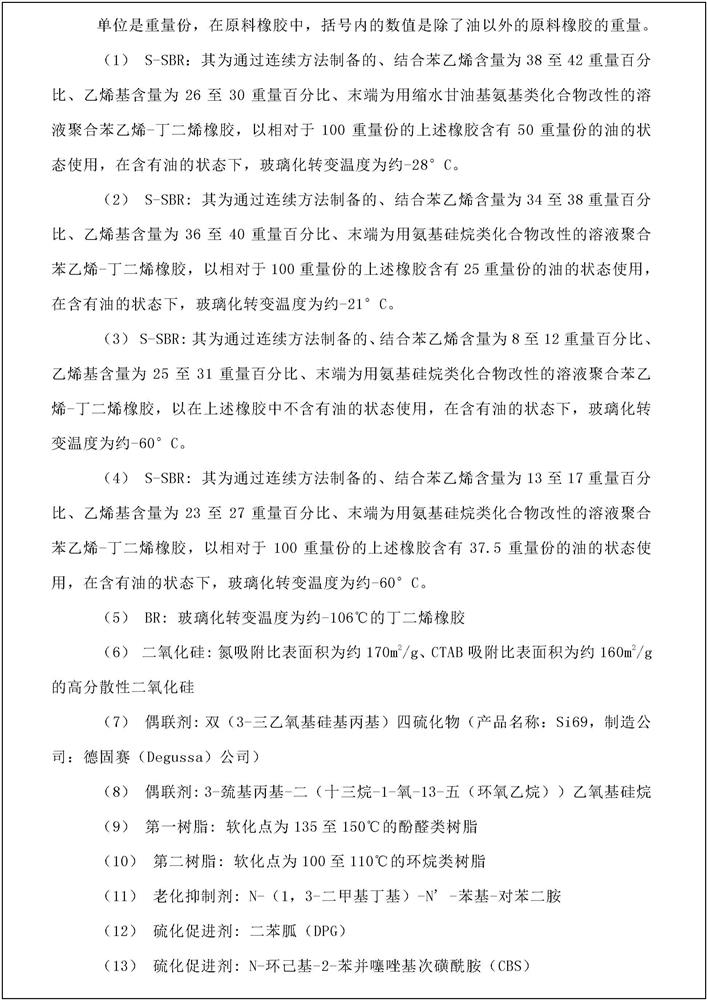

[0119] [Experimental Example 1: Determination of Physical Properties of Prepared Rubber Composition]

[0120] The physical properties of the rubber samples prepared in the above Examples and Comparative Examples were measured, and the results are shown in Table 2 below.

[0121] Table 2

[0122] Comparative example 1 Comparative example 2 Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Mooney viscosity (ML1+4) 78 80 81 79 73 72 68 66 Hardness (ShoreA) 72 74 73 75 75 73 74 74 300% Modulus 105 105 98 102 95 96 98 94 Fracture energy 168 162 172 169 182 187 192 194 wet grip index 100 103 102 102 105 104 106 107 30℃ G*(E+06) 10.2 11.1 10.2 11.2 11.8 11.5 12.3 12.0 tan δ at 60°C 0.173 0.182 0.173 0.178 0.182 0.175 0.171 0.176 60℃ G*(E+06) 7.0 7.5 6.9 7.8 8.2 7.8 8.1 7.9 Lamborn wear index 100 97 105 102 106 109 107 106

[0123]...

experiment example 2

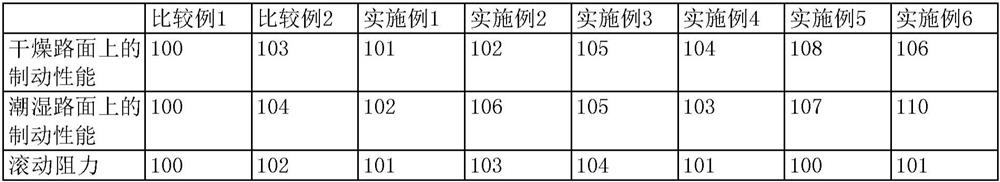

[0131] [Experimental Example 2: Performance Experiment of Tire]

[0132] Treads were manufactured using the rubbers prepared in the above-mentioned Examples and Comparative Examples, and then 245 / 40ZR18-sized tires using the above-mentioned treads as semi-finished products were manufactured. The brake performance and rolling resistance on dry and wet roads of the above tires were tested, and then the relative ratios of Examples 1 to 6 and Comparative Example 2 with respect to the results of the tire of Comparative Example 1 are shown in Table 3 below.

[0133] table 3

[0134]

[0135] Referring to the above-mentioned Table 3, it can be confirmed that in the case of the tires of Examples 1 to 6, by maintaining the rolling resistance at the same level as before, it is possible to minimize the impairment of the low fuel consumption performance and realize extremely dry roads and wet roads Excellent braking performance and high handling performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com