pneumatic tire

A pneumatic tire and tire technology, applied in tire parts, textiles and papermaking, transportation and packaging, etc., can solve problems such as driver discomfort, achieve easy formation, excellent low fuel consumption performance, and suppress radio noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

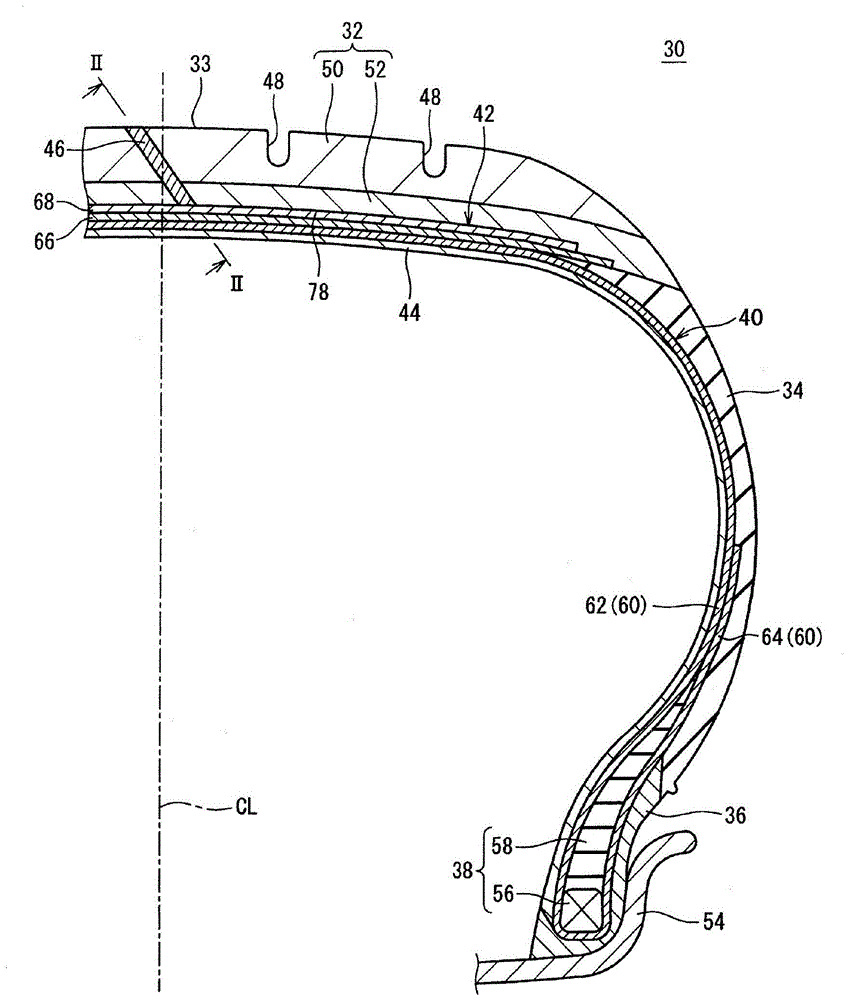

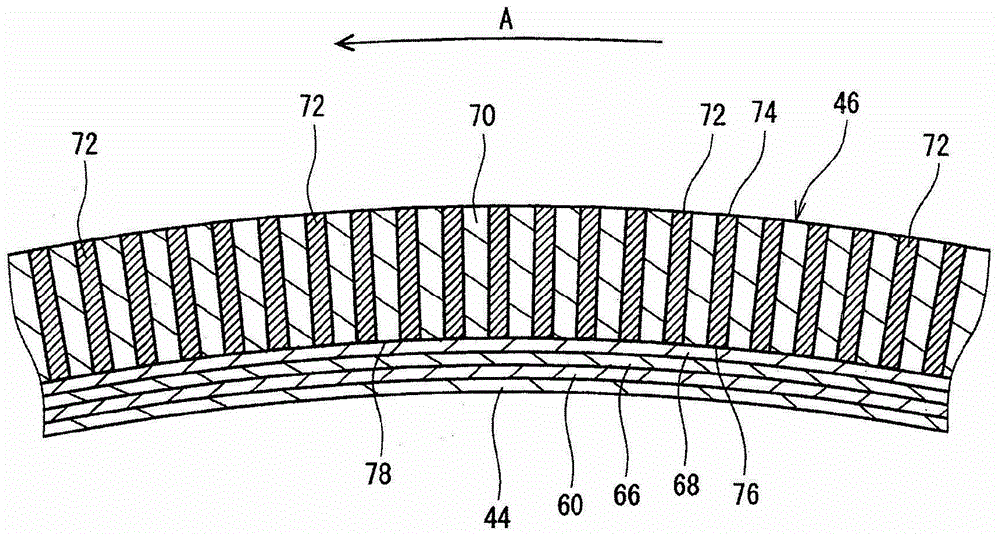

Embodiment 1

[0130] made with Figure 1~3 The structure of the tire shown. The size of this tire is "195 / 65R15". The tire has a through portion. The penetrating portion has a topping rubber and a cord. The topping rubber is molded by crosslinking a rubber composition. The rubber composition comprises: 100 parts by mass of styrene-butadiene copolymer (trade name "SBR1500" of JSR Company), 50 parts by mass of silicon dioxide (trade name "ULTRASIL VN3" of Degussa Company), 5 parts by mass Parts of silane coupling agent (trade name "Si69" of Degussa Company), 1 mass part of wax (trade name "SUNNOC N" of Ouchi Shining Chemical Industry Co., Ltd.), 2 mass parts of anti-aging agent (Ouchi Shining Chemical Co., Ltd. Industrial company's trade name "NOCRAC 6C"), 1 part by mass of stearic acid (NOF Corporation), 3 parts by mass of zinc oxide (trade name of Mitsui Metal Mining Co., Ltd. "Yaqianhua No. 1"), 1.5 parts by mass Powdered sulfur (Tsurumi Chemical Co., Ltd.) and 1.5 parts by mass of vu...

Embodiment 2-15

[0135] Tires of Examples 2-15 were obtained in the same manner as in Example 1, except that the specifications of the penetration portions were as shown in Tables 1-4 below.

Embodiment 16

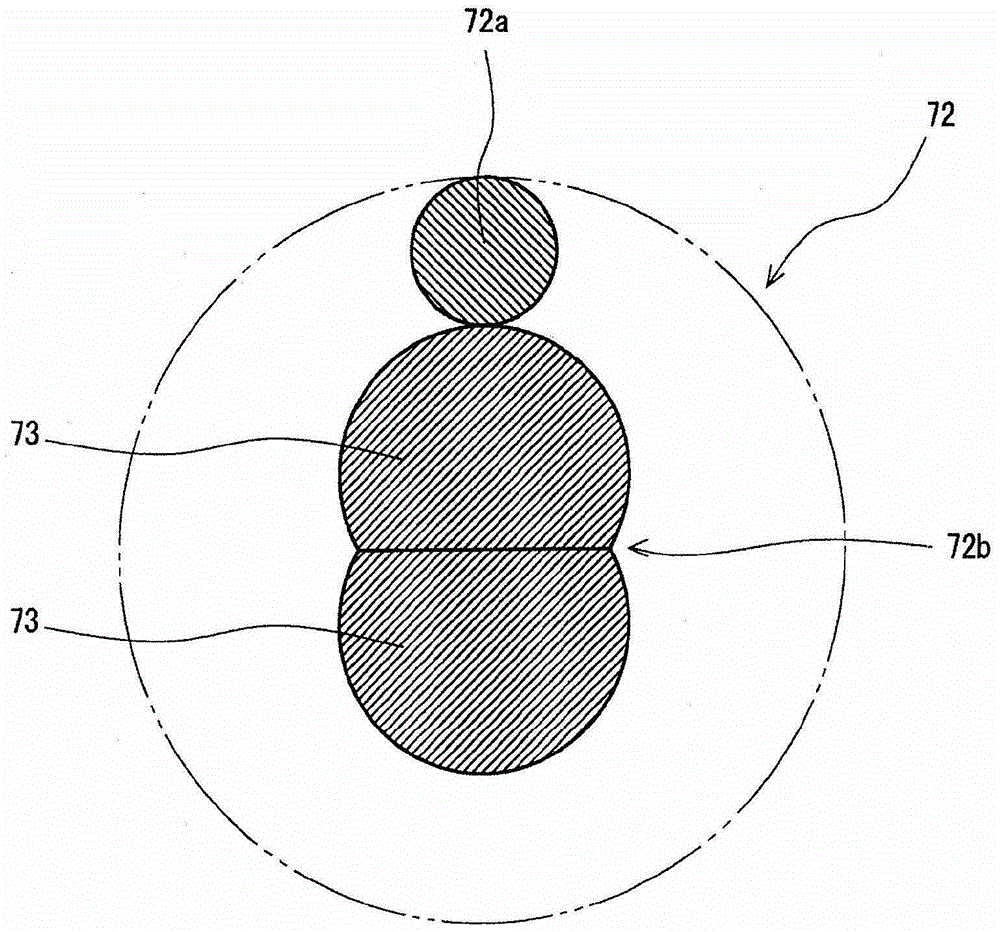

[0141] A tire of Example 16 was obtained in the same manner as in Example 1, except that the specifications of the penetration portion were as shown in Table 5 below. Such as Figure 13 As shown, the cord of this tire has a core and a sheath covering the core. The core consists of conductive filament bundles. Each conductive filament was spun from a resin composition containing 100 parts by mass of nylon 66 and 10 parts by mass of ketjen black. The sheath consists of multiple non-conductive filaments. Each non-conductive filament was spun from nylon 66.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com