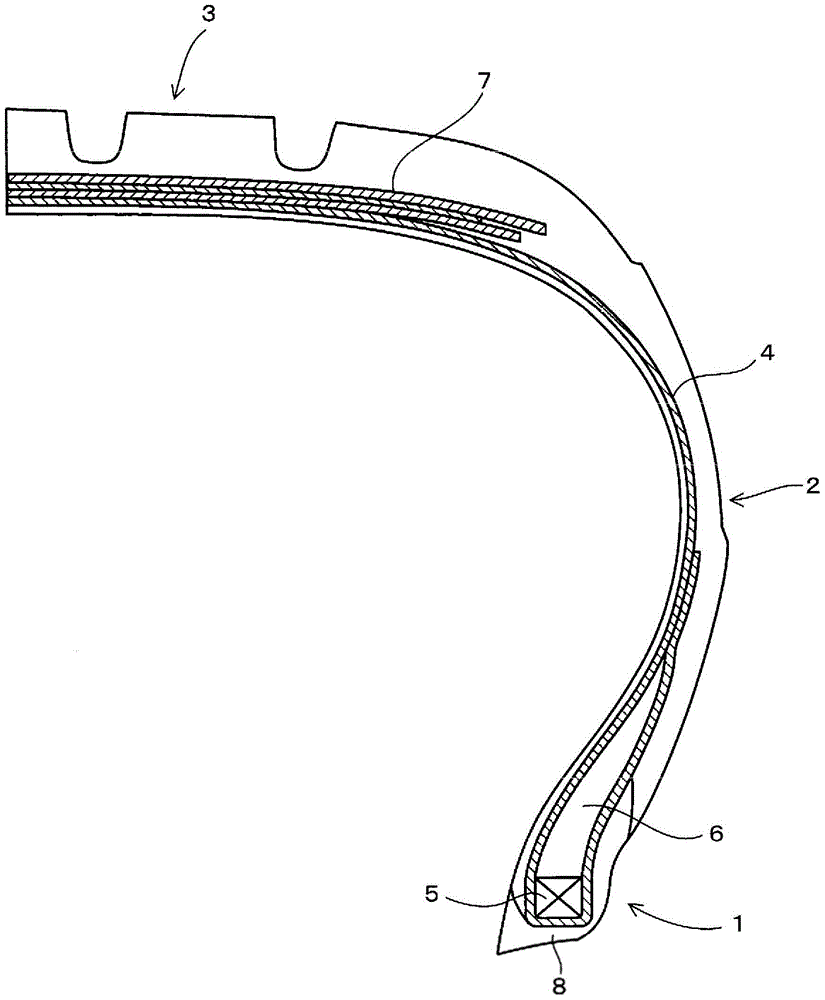

Rubber composition for tire sidewall and pneumatic tire using same

A rubber composition and tire technology, applied in special tires, tire parts, transportation and packaging, etc., to achieve the effects of suppressing the decrease in hardness, improving low fuel consumption, cutting resistance and bending fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

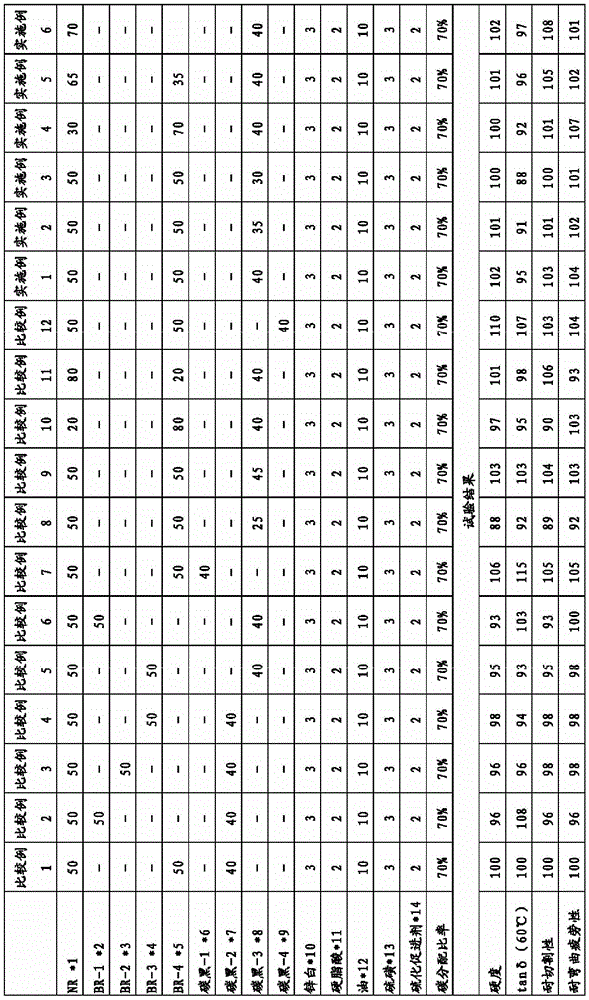

Embodiment 1~6 and comparative example 1~11

[0062] Sample preparation

[0063] In the compounding (parts by mass) shown in Table 1, the vulcanization accelerator and components other than sulfur were kneaded for 5 minutes using a 1.5-liter closed-type Banbury mixer, and then the clinker was released at a temperature of 150°C. And carry out room temperature cooling. Then, the clinker was added with a vulcanization accelerator and sulfur using a roll rubber mixer, and kneaded for 2 minutes to obtain a rubber composition for tire sidewalls. Then, the obtained rubber composition was vulcanized under pressure at 160° C. for 20 minutes in a prescribed mold to prepare a vulcanized rubber test piece. The physical properties of the obtained rubber composition or vulcanized rubber test piece were measured by the following test methods.

[0064] Hardness: The Shore A hardness at 20°C was measured in accordance with JIS K6253. The result is shown with the value of Comparative Example 1 as an index of 100. The larger the index, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com