Vulcanized rubber composition and tire using same

A vulcanized rubber and composition technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of inability to achieve wear resistance, damage resistance, low fuel consumption, and deterioration of system dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

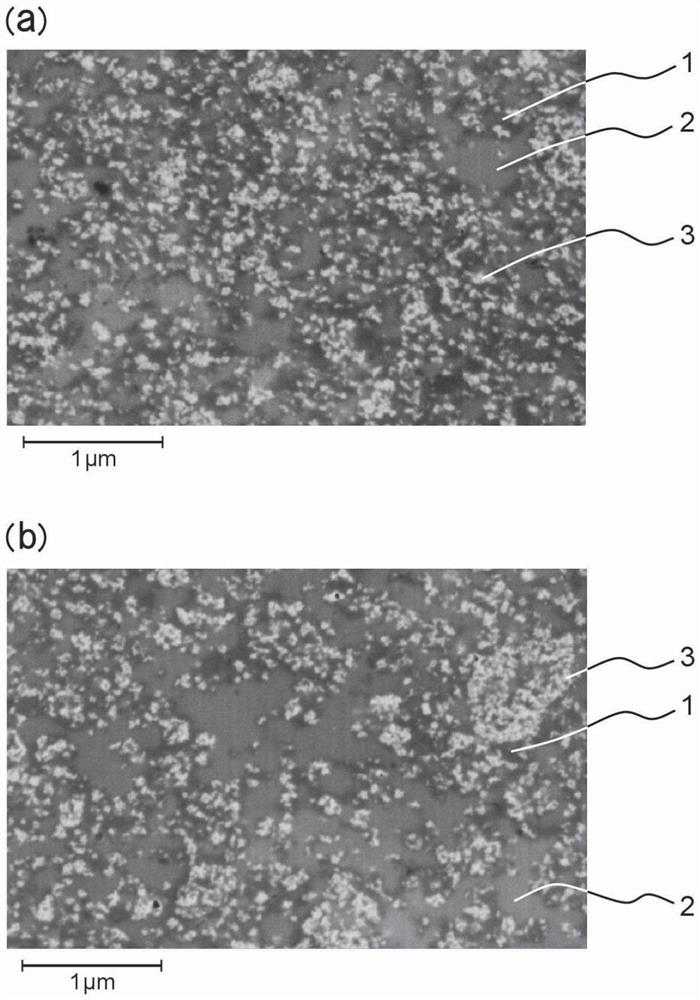

Image

Examples

Embodiment 1~6 and comparative example 1~3

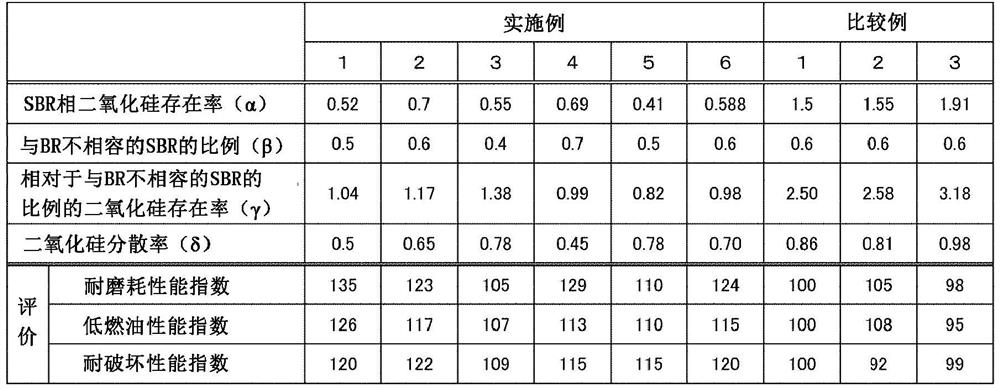

[0093] For each vulcanized rubber composition whose indexes α, β, γ, and δ of the vulcanized rubber composition have the values shown in Table 1, the following tests were used to evaluate wear resistance performance, low fuel consumption performance and fracture resistance performance. The results of each test are listed in Table 1. It should be noted that, regarding the measurement and evaluation of α, δ, wear resistance performance, low fuel consumption performance, and damage resistance performance, the vulcanized rubber composition was stored at room temperature, and after 200 hours (about 1 week) after the vulcanization was completed, Measurements and evaluations were performed on vulcanized rubber compositions. β corresponds to the content (mass) of styrene butadiene rubber incompatible with butadiene rubber relative to the total rubber component (mass) contained in the production of the vulcanized rubber composition, and γ is α / β.

[0094]

[0095] Using the Lambou...

Synthetic example 1

[0128] Synthesis Example 1: Synthesis of SBR1

[0129] 28 g of cyclohexane, 8.6 mmol of tetramethylethylenediamine, and 6.1 mmol of n-butyllithium were added to a 100 ml ampoule purged with nitrogen. Next, 8.0 g of isoprene was gradually added and reacted in an ampoule at 60° C. for 120 minutes to obtain an isoprene block (as an initiator 1).

[0130] Initiator 1 had a weight average molecular weight of 2200, a vinyl bond content of 72.3 (mass %), and a molecular weight distribution (Mw / Mn) of 1.08.

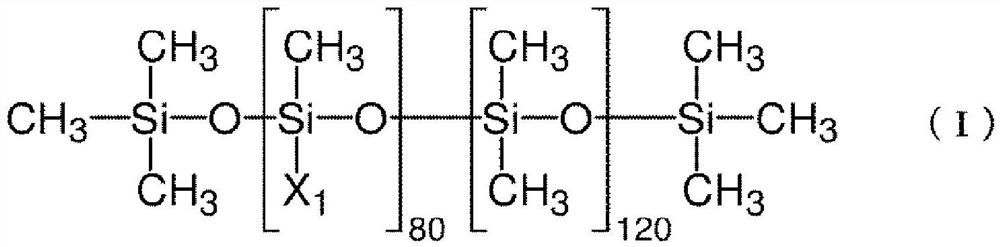

[0131] Next, 4000 g of cyclohexane, 483.5 g of 1,3-butadiene, 211.5 g of styrene, and 0.18 g of tetramethylethylenediamine were charged under a nitrogen atmosphere into an autoclave equipped with a stirrer, and then all the initiators were added. Agent 1, polymerization started at 40°C. After confirming that the polymerization conversion rate reached the range of 95% to 100%, 0.08 mmol of 1,6-bis(trichlorosilyl)hexane was added in the state of a 20% by mass concentration of cyc...

Synthetic example 2

[0147] Synthesis Example 2: Synthesis of SBR2

[0148] Cleaning, drying, and replacement with dry nitrogen in a stainless steel polymerization reactor with an internal volume of 20 liters, and hexane (specific gravity 0.68g / cm 3 ) 10.2kg, 547g of 1,3-butadiene, 173g of styrene, 6.1ml of tetrahydrofuran, and 5.0ml of ethylene glycol diethyl ether were put into the polymerization reactor. Next, 13.1 mmol of n-butyllithium was added as a n-hexane solution to start polymerization.

[0149]The stirring rate was set at 130 rpm, the temperature in the polymerization reactor was set at 65° C., and the monomers were continuously supplied into the polymerization reactor, while performing copolymerization of 1,3-butadiene and styrene for 3 hours. The supplied amount of 1,3-butadiene in all polymerizations was 821 g, and the supplied amount of styrene was 259 g.

[0150] Next, the obtained polymer solution was stirred at a stirring rate of 130 rpm, 11.1 mmol of 3-diethylaminopropyltriet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com