Low-temperature PTC conducting composition, PTC over-current protection device and manufacturing method of PTC over-current protection device

A technology for overcurrent protection devices and conductive compositions, which is applied in the direction of resistors with positive temperature coefficients, conductive materials dispersed in non-conductive inorganic materials, etc., which can solve the problems of insufficient resistance self-recovery ability, heat resistance, Poor aging, poor resistance stability and other problems, to achieve the effect of excellent resistance stability, low operating temperature, high PTC strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

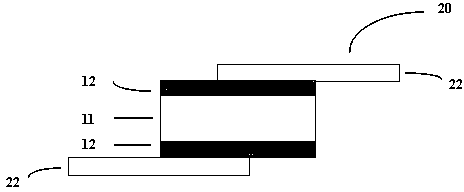

Image

Examples

Embodiment 1

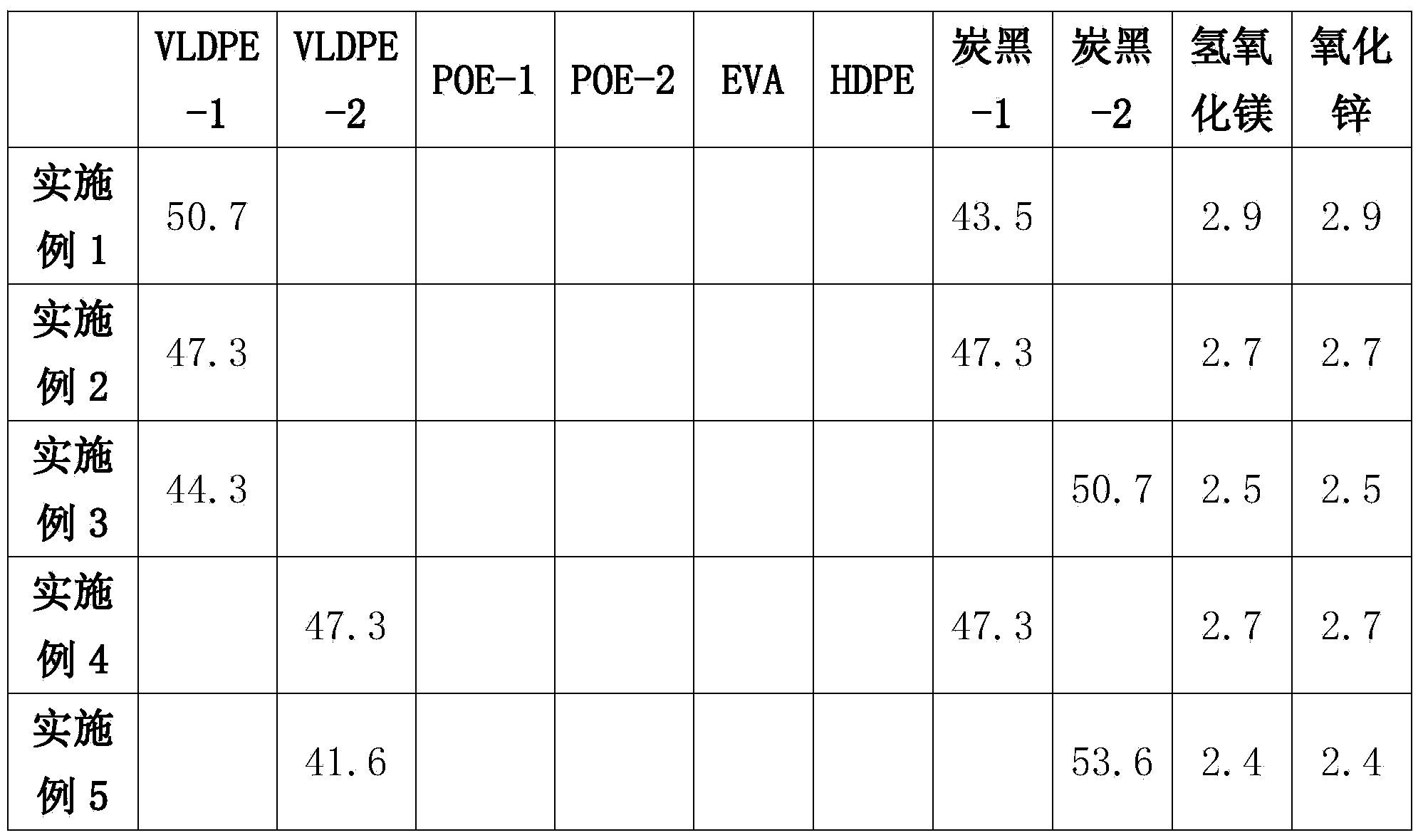

[0038] The composition and weight ratio of the PTC conductive composition of the present embodiment are as follows:

[0039]50.7wt% very low density polyethylene (VLDPE-1, Exact4023, melt index 3.5g / 10min, density 0.882g / cm 3 , melting point 73°C, Exxon Company), 43.5wt% conductive carbon black (carbon black-1: 3030B, particle size 55nm, DBP value 130cm 3 / 100g, Mitsubishi Carbon), 2.9wt% magnesium hydroxide (Mg(OH) 2 , HT-206, particle size 2μm, Jinan Taixing Chemical Industry), 2.9wt% zinc oxide (ZnO, ZHZn-01, particle size 40nm, Wuxi Huize Chemical Industry).

[0040] Weigh according to the mass ratio, and in order, add VLDPE-1 to the internal mixer with a set temperature of 100°C and a speed of 30r / min, banbury for 4 minutes until it melts, then add carbon black and banbury for 8 minutes, and finally add Magnesium hydroxide and zinc oxide were banburyed for 5 minutes to obtain a PTC conductive composition with PTC characteristics.

[0041] The above-mentioned PTC conduc...

Embodiment 2

[0046] The PTC device was fabricated according to the same method as described in Example 1, but the content of VLDPE-1 (Exact4023) was changed from 50.7wt% to 47.3wt%, and the content of conductive carbon black (carbon black-1, 3030B) was changed from 43.5 The wt% changed to 47.3wt%, the content of magnesium hydroxide (HT-206) changed from 2.9wt% to 2.7wt%, and the content of zinc oxide (ZHZn-01) changed from 2.9wt% to 2.7wt%. The physical properties of the PTC device were tested in the same manner as described in Example 1, and the results are listed in Table 2.

Embodiment 3

[0048] Manufacture the PTC device according to the same method as described in Example 1, but with 48.4wt% conductive carbon black (carbon black-2, Raven410, particle size 101nm, DBP value 65cm 3 / 100g, Columbian company) instead of 43.5wt% conductive carbon black (carbon black-1, 3030B) in Example 1, the content of VLDPE-1 (Exact4023) is changed from 50.7wt% to 44.3wt%, magnesium hydroxide ( HT-206) content changed from 2.9wt% to 2.5wt%, zinc oxide (ZHZn-01) content changed from 2.9wt% to 2.5wt%. The physical properties of the PTC device were tested in the same manner as described in Example 1, and the results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com