Polymer-carbon nanotube-carbon black composite temperature self-regulating positive temperature coefficient (PTC) electric heating material

A heating material, carbon nanotube technology, applied in resistors with positive temperature coefficient, dyed polymer organic compound treatment, fibrous fillers, etc., can solve the problems of uneven dispersion, unstable material properties, difficulties and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

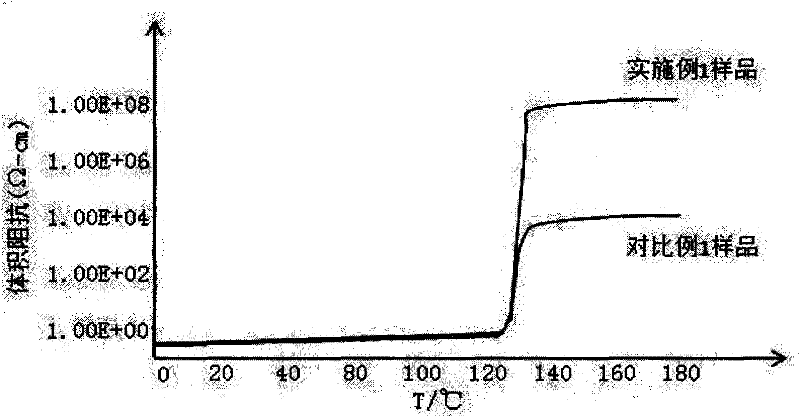

Embodiment 1

[0023] Polymer matrix one: high-density polyethylene HDPE (1): density: 0.953g / cm 3 , melt index: 0.95g / 10min, melting point: 131°C, 15.51g.

[0024] Polymer matrix two: high-density polyethylene HDPE (2): density: 0.962g / cm 3 , melt index: 6.0g / 10min, melting point: 135°C, 3.88g.

[0025] Inorganic filler: magnesium hydroxide: 4.18g.

[0026] High-density polyethylene maleic anhydride grafted polymer: 2.91 g.

[0027] Antioxidant: 0.02g.

[0028] Carbon black: 19.05 g.

[0029] Carbon nanotubes: 0.93 g.

[0030] Process:

[0031] 1). Dispersion of carbon nanotubes: placing carbon nanotubes (CNTs) in 1 wt% PVP aqueous solution and stirring. Use Branson Digital Sonifier (Model 250) Sonicate Tip to carry out ultrasonic dispersion for 10min (30W), and then centrifuge it (3000rpm, 5min). Pour off the supernatant, filter the precipitate with a 0.2 μm PTFE membrane, dry it, and weigh it. About 70% of the CNTs are suspended in the aqueous phase. Mix HDPE (1) (powder) and CN...

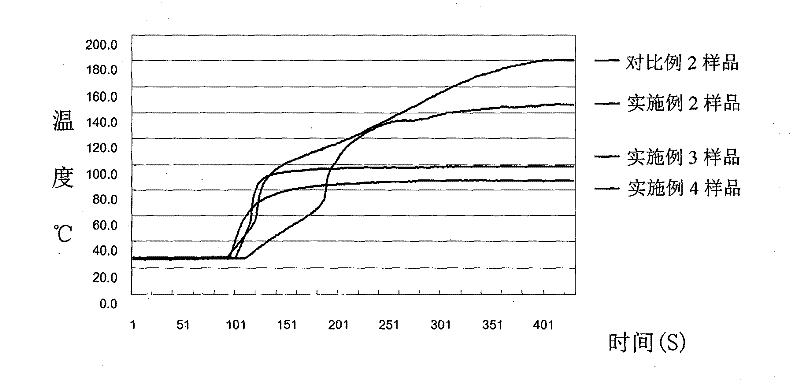

Embodiment 2

[0059] Polymer matrix: high-density polyethylene HDPE (1): HDPE (1): Density: 0.953g / cm 3 , melt index: 0.95g / 10min, melting point: 131°C, 20.04g.

[0060] Inorganic filler: magnesium hydroxide: 4.09g.

[0061] High-density polyethylene maleic anhydride grafted polymer: 3.02 g.

[0062] Antioxidant: 0.02g.

[0063] Carbon black: 17.71 g.

[0064] Carbon nanotubes: 0.45 g.

[0065] Process:

[0066] 1). Dispersion of carbon nanotubes: placing carbon nanotubes (CNTs) in 1 wt% PVP aqueous solution and stirring. Use Branson Digital Sonifier (Model 250) Sonicate Tip to carry out ultrasonic dispersion for 10min (30W), and then centrifuge it (3000rpm, 5min). Pour off the supernatant, filter the precipitate with a 0.2 μm PTFE membrane, dry it, and weigh it. About 70% of the CNTs are suspended in the aqueous phase. Mix HDPE (1) (powder) and CNT according to a certain ratio to ensure that HDPE can be completely immersed in the aqueous phase solution of CNT. Then vacuum dry at 9...

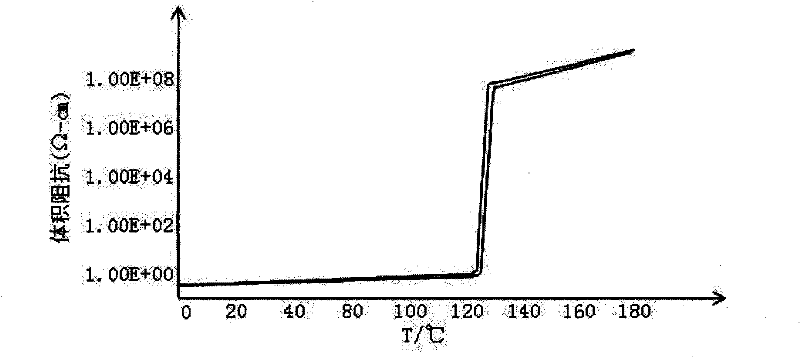

Embodiment 3

[0074] Polymer base: Low-density polyethylene LDPE: Melt index: 3.5g / 10min, 20.04g.

[0075] Inorganic filler: magnesium hydroxide: 4.09g.

[0076] High-density polyethylene maleic anhydride grafted polymer: 3.02 g.

[0077] Antioxidant: 0.02g.

[0078] Carbon black: 17.71 g.

[0079] Carbon nanotubes: 0.45 g.

[0080] Process:

[0081] 1). Dispersion of carbon nanotubes: placing carbon nanotubes (CNTs) in 1 wt% PVP aqueous solution and stirring. Use Branson Digital Sonifier (Model 250) Sonicate Tip to carry out ultrasonic dispersion for 10min (30W), and then centrifuge it (3000rpm, 5min). Pour off the supernatant, filter the precipitate with a 0.2 μm PTFE membrane, dry it, and weigh it. About 70% of the CNTs are suspended in the aqueous phase. Mix LDPE (powder) and CNT according to a certain ratio to ensure that LDPE can be completely immersed in the aqueous solution of CNT. Then vacuum dry at 90°C for 2 to 3 hours to completely remove the moisture.

[0082] 2). Mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com