Ultrathin hard alloy tool bit structure with center partition

A cemented carbide knife and cemented carbide technology, which is applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problem of unstable quality of cemented carbide cutter heads, affecting the cutting quality of alloy cutter heads, and the hardness of cutter head alloys. Non-uniformity and other problems, to achieve the effect of good market promotion value, improved sintering stability, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

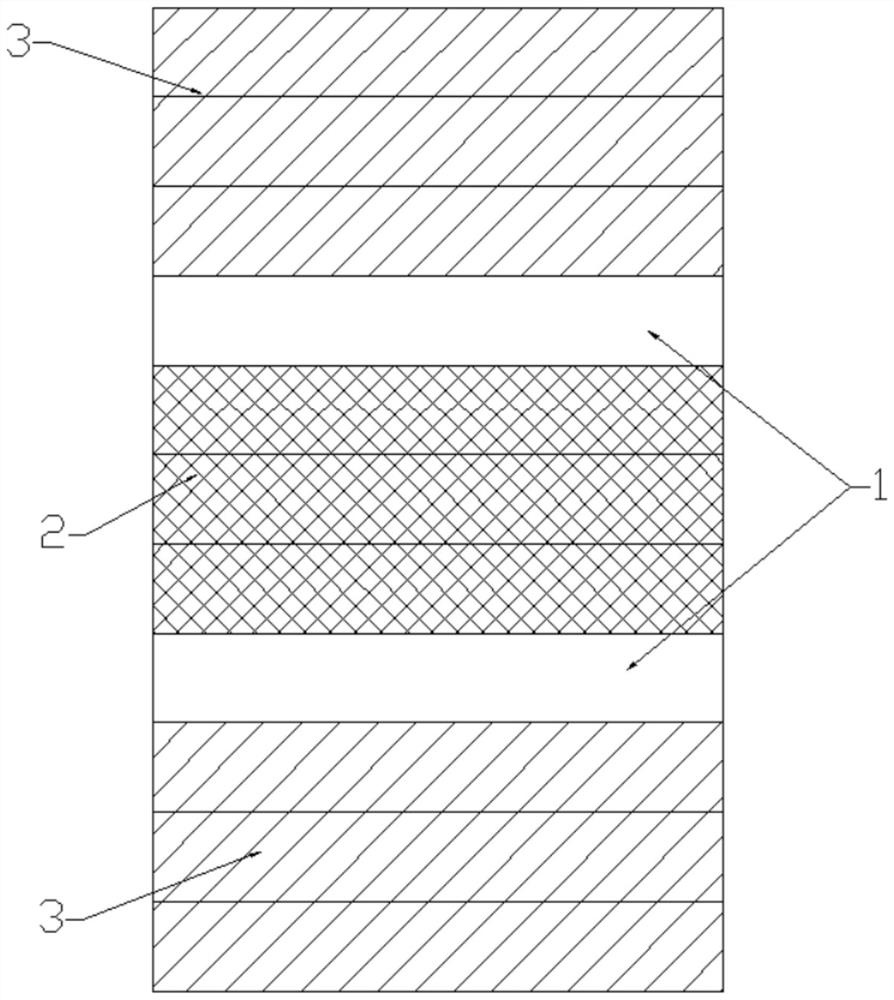

[0019] As shown in the figure, an ultra-thin cemented carbide cutter head structure with a central partition includes an even number of cemented carbide cutter head layers 1, and graphite is arranged between the two adjacent cemented carbide cutter head layers 1 in the middle. Graphite mold indenters 3 are provided on the outer sides of the mold center partition layer 2 and the outermost two cemented carbide cutter head layers 1 .

[0020] The number of the cemented carbide cutter head layer 1 is two layers, the graphite mold center partition layer 2 is located between the two cemented carbide cutter head layers 1, and the graphite mold indenter 3 is located between the two cemented carbide cutter heads. Both sides of the head layer 1.

Embodiment 2

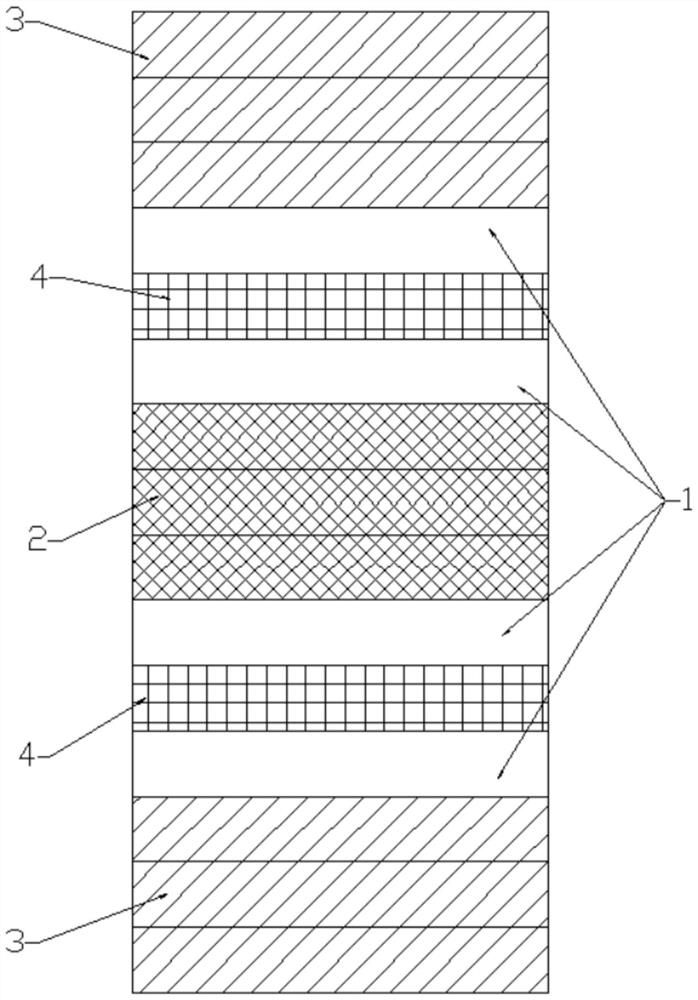

[0022] As shown in the figure, an ultra-thin cemented carbide cutter head structure with a central partition includes an even number of cemented carbide cutter head layers 1, and graphite is arranged between the two adjacent cemented carbide cutter head layers 1 in the middle. Graphite mold indenters 3 are provided on the outer sides of the mold center partition layer 2 and the outermost two cemented carbide cutter head layers 1 .

[0023] The quantity of described cemented carbide cutter head layer 1 is four layers, and graphite mold layer 4 is arranged between the cemented carbide cutter head layers 1 on the same side of described graphite mold central partition layer 2, and described graphite mold central partition layer 2 The two sides are successively a cemented carbide cutter head layer 1, a graphite mold layer 4, a cemented carbide cutter head layer 1, and a graphite mold indenter 3.

Embodiment 3

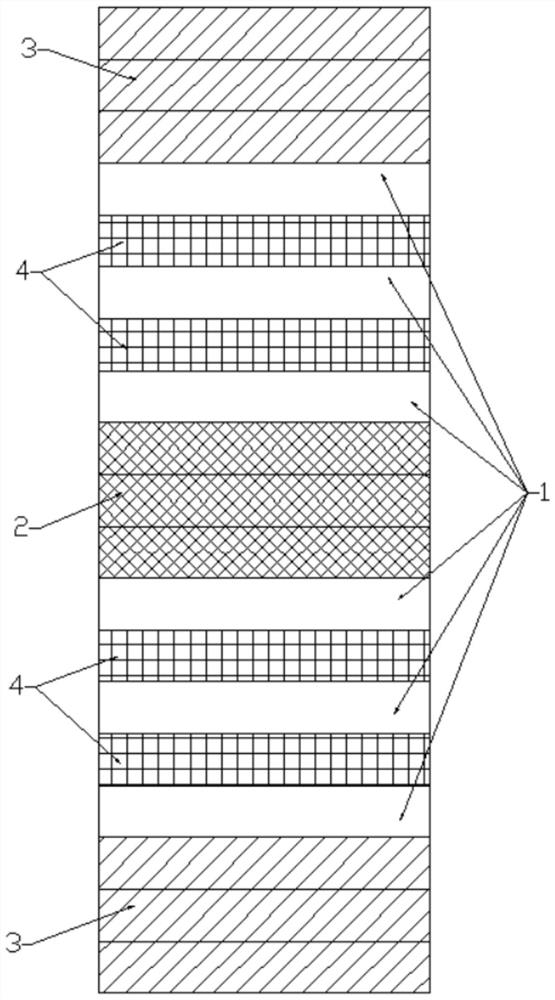

[0025] As shown in the figure, an ultra-thin cemented carbide cutter head structure with a central partition includes an even number of cemented carbide cutter head layers 1, and graphite is arranged between the two adjacent cemented carbide cutter head layers 1 in the middle. Graphite mold indenters 3 are provided on the outer sides of the mold center partition layer 2 and the outermost two cemented carbide cutter head layers 1 .

[0026] The number of the cemented carbide cutter head layer 1 is six layers, and the graphite mold center partition layer 2 is provided with a graphite mold layer 4 between the cemented carbide cutter head layers 1 on the same side of the graphite mold center partition layer 2 The two sides are successively a cemented carbide cutter head layer 1, a graphite mold layer 4, a cemented carbide cutter head layer 1, a graphite mold layer 4, a cemented carbide cutter head layer 1, and a graphite mold indenter 3.

[0027] When the present invention is actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com