A kind of nanometer microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and nanotechnology, applied in ceramics, inorganic insulators and other directions, can solve the problems of Q*f value and ceramic reliability decline, poor sintering stability of crystal structure, and difficulty in obtaining pure equality, and achieve good sintering stability, The effect of stable sintering and suitable for large-scale industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also provides a method for preparing the nano-microwave dielectric ceramic material described in the above technical solution, comprising the following steps:

[0055] a) After mixing the rare earth oxide, barium carbonate, aluminum oxide and titanium dioxide, performing the first grinding treatment, and then pre-sintering to obtain a pre-sintered powder;

[0056] b) crushing and sieving the calcined powder obtained in step a), mixing it with a sintering aid, performing a second grinding treatment, and then sequentially performing compression molding and sintering to obtain a nano-microwave dielectric ceramic material.

[0057] In the invention, the rare earth oxide, barium carbonate, aluminum oxide and titanium dioxide are firstly mixed, and then the first grinding treatment is carried out, and then the pre-sintering is carried out to obtain the pre-sintered powder. In the present invention, there is no special limitation on the sources of the rar...

Embodiment 1

[0078] (1) Magnesium oxide, niobium pentoxide, yttrium oxide, cerium oxide and manganese carbonate with a molar ratio of 4:1:0.004:0.53:0.088 are mixed in deionized water, and the quality of the deionized water is the total amount of the powder. 80% of the mass, stirred in a high-speed mixer for 12 hours; then spray-dried with spray drying equipment to obtain dried powder particles; then sieved the dried powder particles with 120 mesh and 240 mesh to remove fine powder and Coarse powder to obtain powder after sieving.

[0079] (2) Put the sieved powder obtained in step (1) in a corundum crucible, and calcinate at 1085° C. for 105 min in an oxidizing atmosphere to obtain a composite oxide powder.

[0080] (3) Mix the composite oxide powder obtained in step (2) with 60% deionized water relative to the mass of the powder, and after stirring for 30 minutes, introduce it into a ball mill tank for ball milling until the particle size D50 is 3.0 μm to 4.0 μm , when the maximum parti...

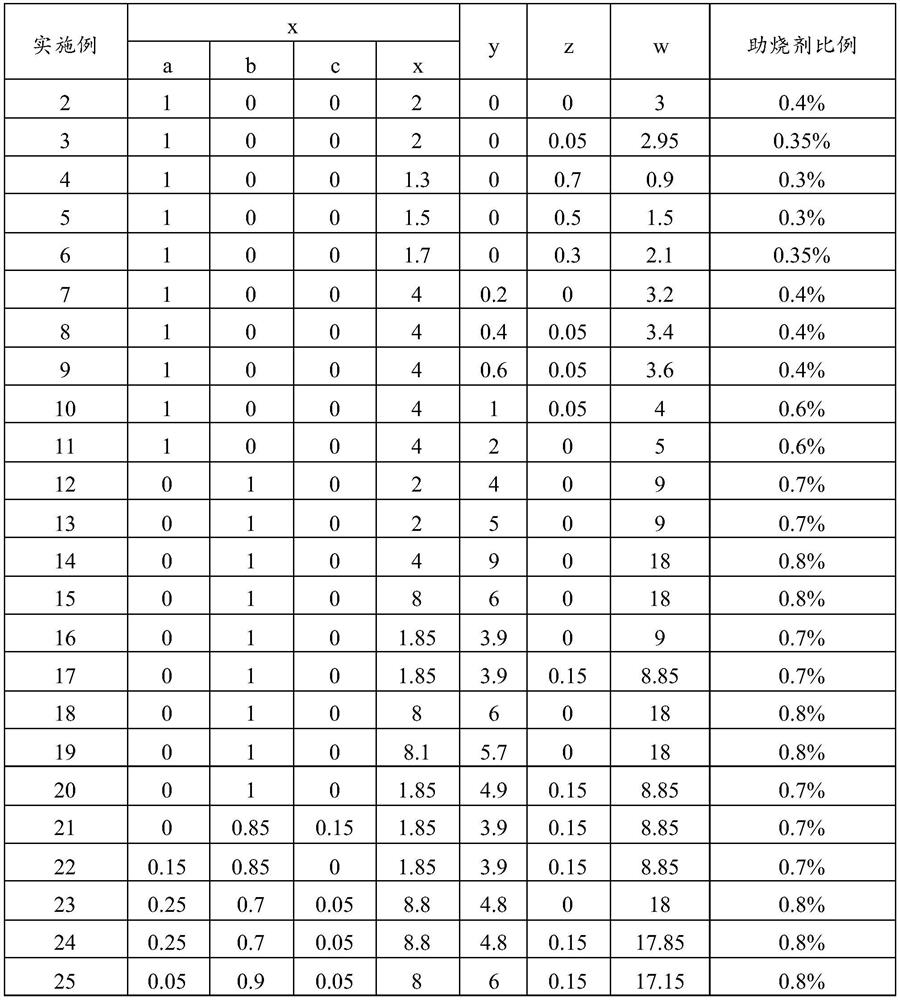

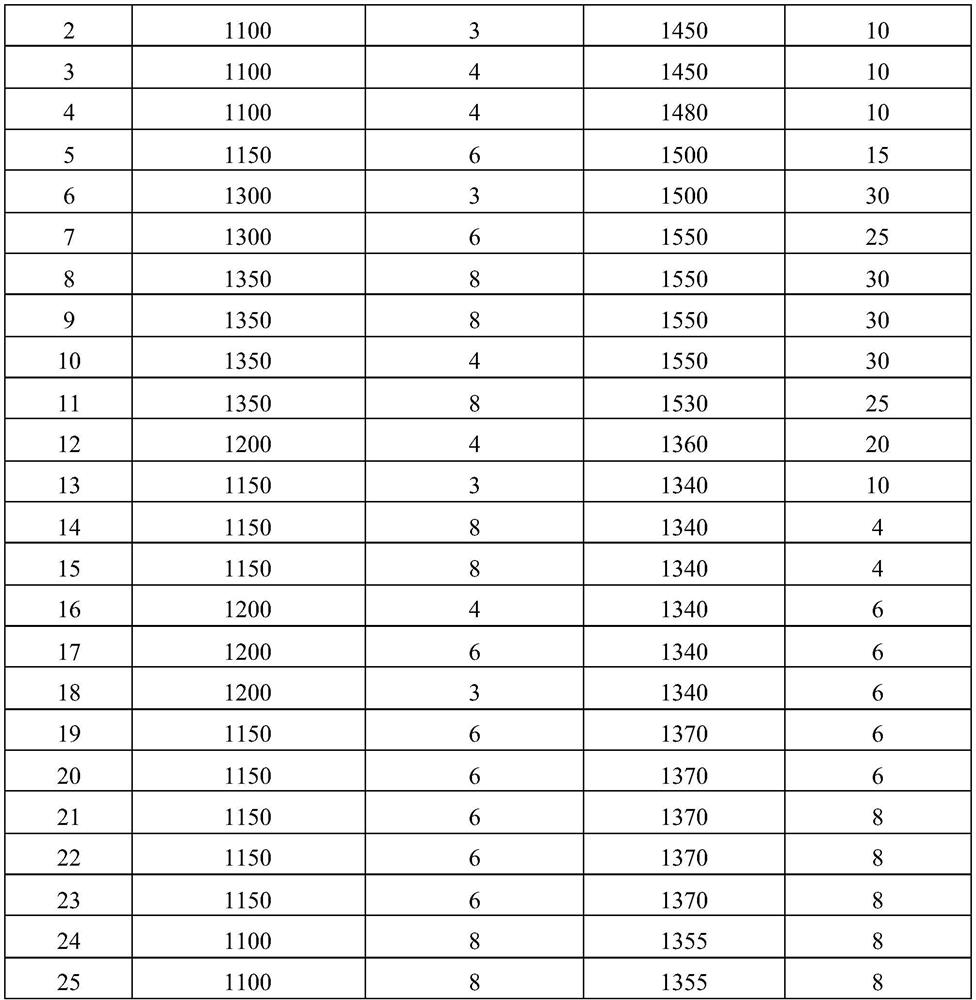

Embodiment 2~25

[0082] (1) The rare earth oxide (Ln 2 o 3 ), barium carbonate, aluminum oxide and titanium dioxide are mixed and stirred evenly with a mixer, fermented with pure water for 24 hours, then sand-milled with a sand mill until the particle size range is 0.1 μm≤D0.5≤0.3 μm, discharged, and spray-dried to obtain The powder after the first grinding process; the Ln 2 o 3 The chemical composition is specifically aLa 2 o 3 -bSm 2 o 3 -cNd 2 o 3 .

[0083] (2) Pre-sintering the powder after the first grinding treatment obtained in step (1) at a temperature of 1000° C. to 1350° C. for 3 hours to 8 hours to obtain a calcined powder.

[0084] (3) The calcined powder obtained in step (2) is pulverized, passed through an 80-mesh sieve, and mixed with the sintering aid provided in Example 1. 0.3% to 0.8%, stir evenly with a mixer, and add dispersant, defoamer, defoamer to control the pH of the slurry between 6 and 8, and then sand again with a sand mill until the particle size range i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com