A kind of graphene modified cemented carbide and preparation method thereof

A technology of graphene modification and cemented carbide, which is applied in the field of preparation of cemented carbide materials and graphene modified cemented carbide. Efficient and rapid preparation, avoiding cumbersome processes, and improving the effect of sintering stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

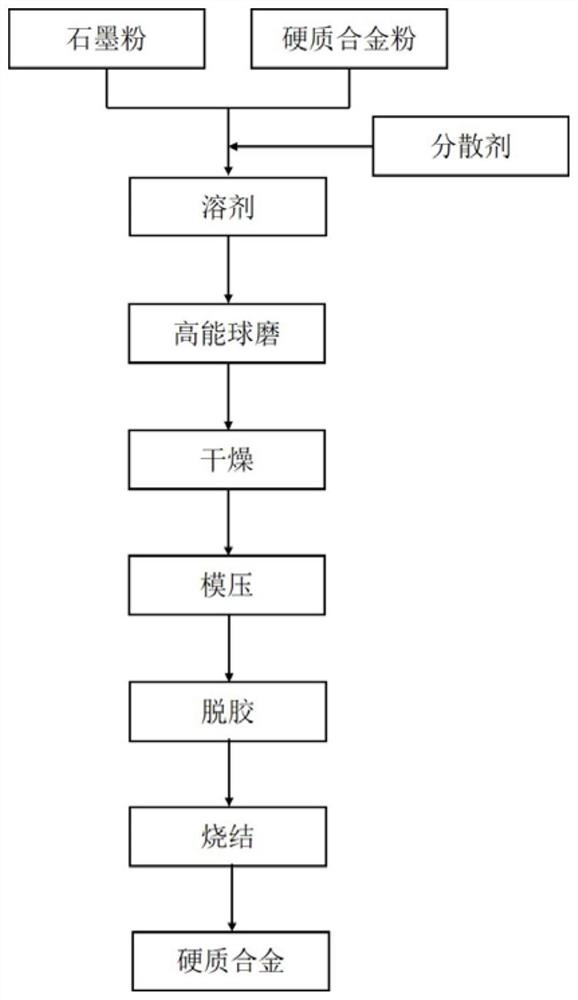

[0019] see figure 1 As shown, one aspect of the embodiments of the present invention provides a method for preparing a graphene-modified cemented carbide, which includes:

[0020] Uniformly mix graphite, dispersant, cemented carbide and solvent, and perform high-energy ball milling to exfoliate graphite into graphene to obtain cemented carbide composite powder containing graphene and cemented carbide;

[0021] The cemented carbide composite powder is granulated, pressed, degummed and sintered to obtain a graphene-modified cemented carbide.

[0022] Further, the graphite includes natural flake graphite and / or expanded graphite.

[0023] Furthermore, the graphite sheet diameter is 1 μm-5 mm.

[0024] Further, the content of graphite in the cemented carbide composite powder is 0.05-5 wt%.

[0025] Further, the cemented carbide includes a combination of at least one of carbides such as WC, CrC and TaC, and Co.

[0026] Furthermore, the cemented carbide contains 80-95wt% WC, 0....

Embodiment 1

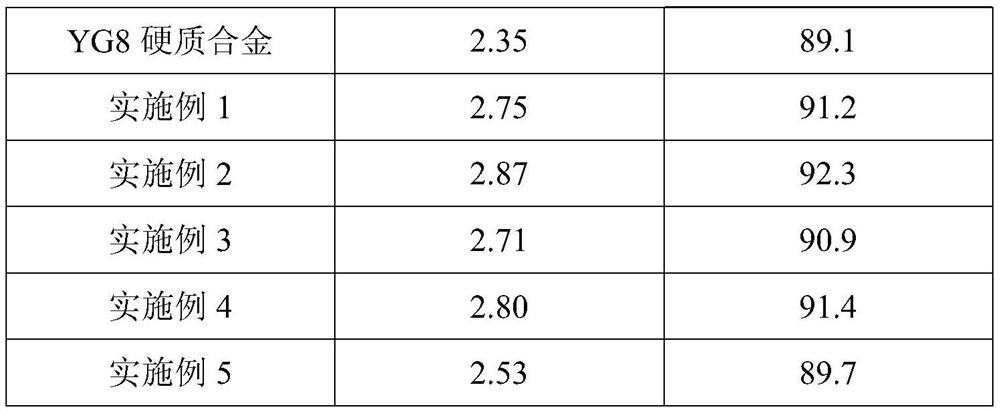

[0047]Mix natural flake graphite (mass fraction of 1wt%) with a sheet diameter of 1mm, polyvinylpyrrolidone (mass fraction of 1wt%), WC, CrC, Co and other powders (YG8 cemented carbide powder) in ethanol, and pass through planetary Ball milling, the grinding medium is a cemented carbide ball with a diameter of 5 mm, the rotation speed is 500 rpm, and the grinding is performed for 48 hours, followed by drying to obtain a cemented carbide composite powder of graphene and cemented carbide powder. The cemented carbide composite powder was mixed and granulated with 2wt% polyvinyl alcohol solution, and then molded under a pressure of 200MPa, followed by degumming at 400°C for 2 hours, and the heating rate was 2°C / min. Then sintering at 1350° C. under low pressure for 5 hours to prepare a graphene-modified cemented carbide material. The bending strength was tested by a three-point bending test method, and the hardness was tested by a Rockwell hardness tester. The test results are sho...

Embodiment 2

[0049] The natural flake graphite (mass fraction is 3wt%) with a sheet diameter of 500 μm is mixed with sodium lauryl sulfate (mass fraction is 1.5wt%), WC, CrC, Co and other powders (YG8 cemented carbide powder) in water, Grinding by planetary ball milling, the grinding medium is a cemented carbide ball with a diameter of 5 mm, the rotation speed is 200 rpm, and the grinding is carried out for 96 hours, followed by drying to obtain a cemented carbide composite powder of graphene and cemented carbide powder. The cemented carbide composite powder was mixed and granulated with 2wt% polyvinyl alcohol solution, and then molded under a pressure of 300MPa, followed by degumming at 400°C for 2 hours, with a heating rate of 2°C / min. Then sintering at 1350° C. under low pressure for 5 hours to prepare a graphene-modified cemented carbide material. The bending strength was tested by a three-point bending test method, and the hardness was tested by a Rockwell hardness tester. The test re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com