Anti-battery effect isolation dielectric paste for thick film circuit

A technology for isolating medium and battery effect, applied to circuits, heterogeneous insulating materials, electrical components, etc., can solve problems such as battery effect and product failure, achieve low pollution, improve stability, and improve chemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

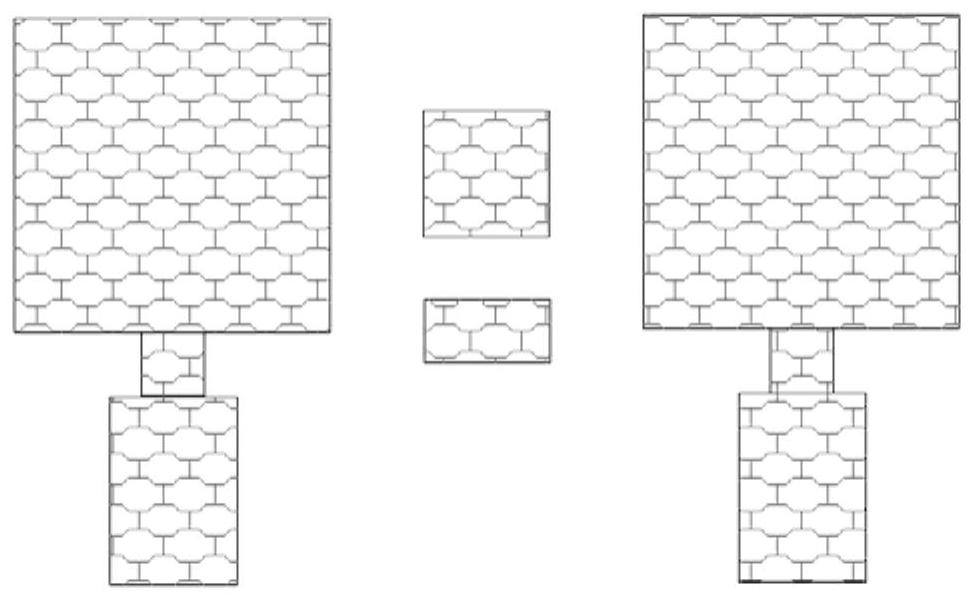

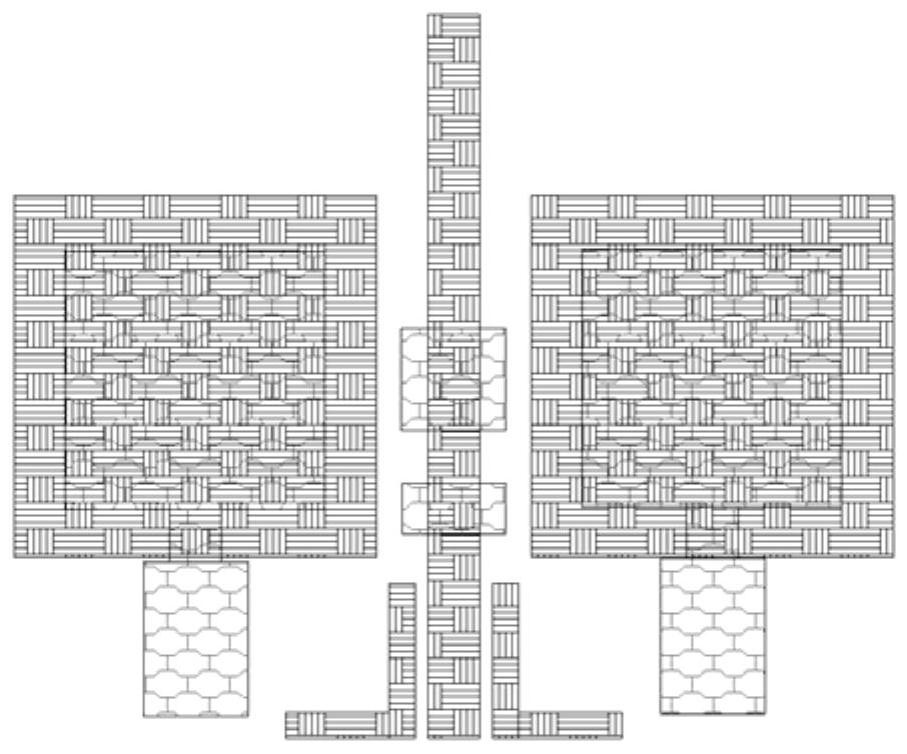

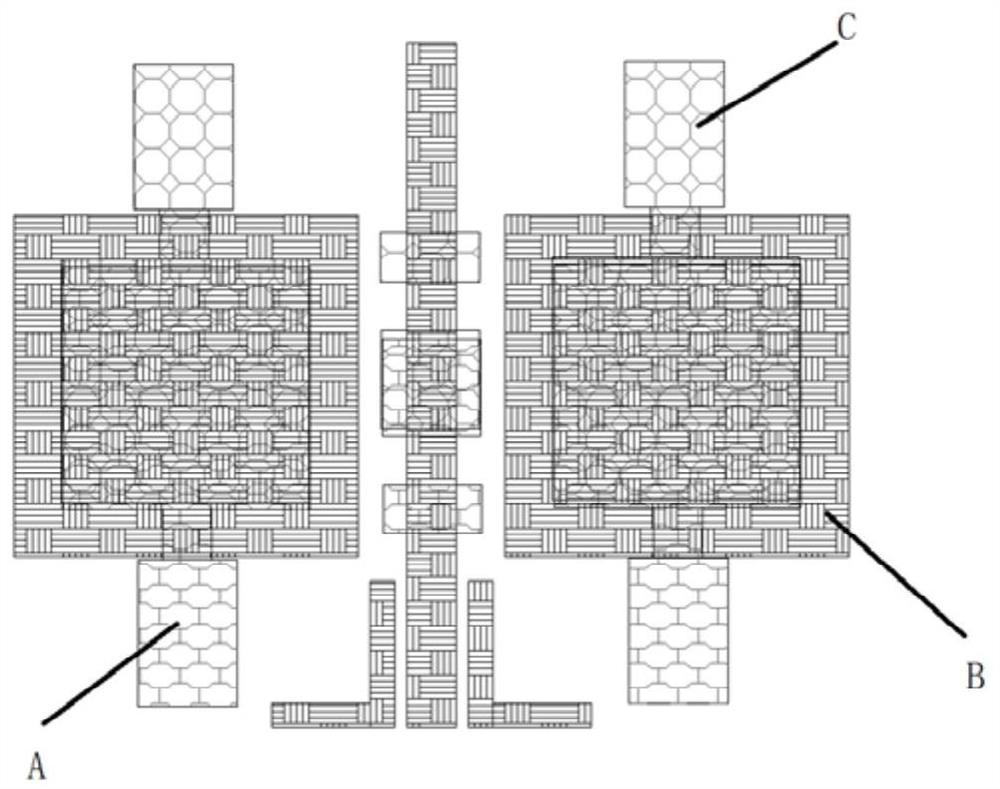

Image

Examples

Embodiment

[0028] Preparation of micron-sized anorthite: After crushing the anorthite ore with a crusher, sieve it with an 80-mesh stainless steel screen, take the undersieve, and then roast it at 800°C for 2 hours, and then ball mill it to a particle size of 1 ~1.3 μm.

[0029] Preparation of glass powder: According to the ratio of oxides listed in Table 1, melting temperature and holding time, after mixing various oxides evenly, the resulting mixture is placed in a melting furnace for melting, and the obtained glass solution is water-quenched to obtain Glass: crush the glass into glass slag, grind the glass slag into a particle size of 1.0-1.3 μm with a ball mill, and dry it to obtain glass powder.

[0030] Table 1 glass powder formula and process parameters

[0031]

[0032] Note: Glass 9 in the table uses Bi 2 o 3 Top up to 100%.

[0033] Preparation of organic carrier: Stir 70g of terpineol and 2g of soybean lecithin in a beaker and heat to 70°C, then add 5g of ethyl cellulos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com